Air reservoir air tightness test bench

A technology of air storage cylinder and cylinder plug, which is applied in the use of liquid/vacuum degree for liquid tightness measurement, and by detecting the appearance of fluid at the leak point, etc. Efficiency and other issues, to achieve the effect of high degree of automation, reasonable structural design, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0019] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

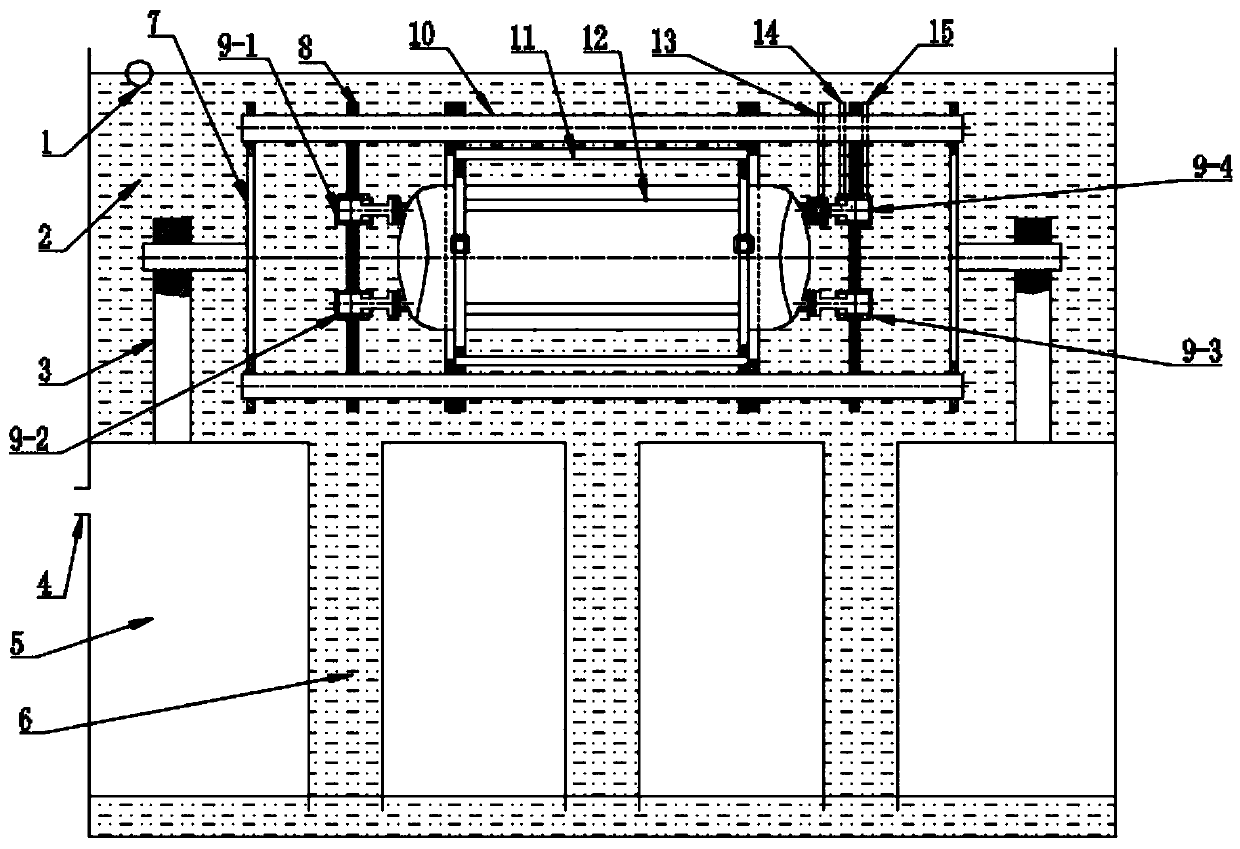

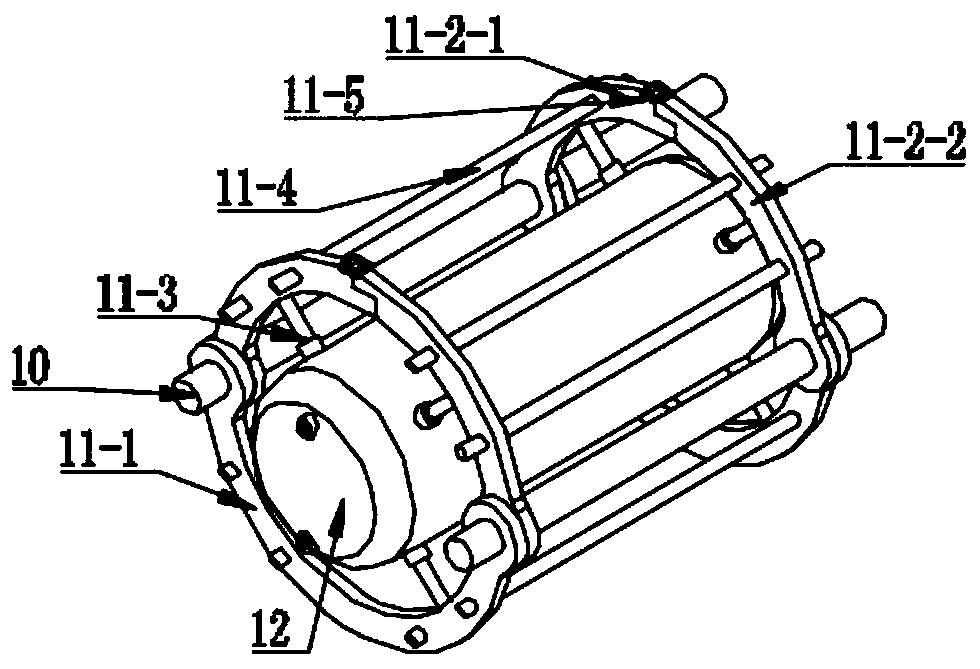

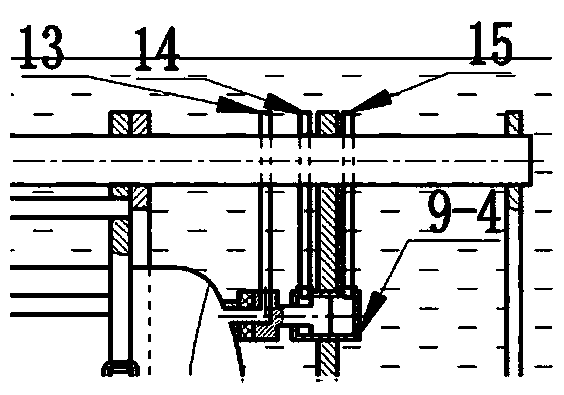

[0020] see Figure 1~3 , in an embodiment of the present invention, an airtightness test bench for an air storage tank, which includes: an upper water tank 2 and a lower water tank 5, and the upper water tank 2 and the lower water tank 5 are communicated through a connecting pipe 6; the left side of the lower water tank 5 An air filling port 4 is provided; a liquid level sensor 1 is provided in the upper water tank 2, and the liquid level sensor 1 is used to detect the liquid level height in the upper water tank 2, which is convenient for the user to monitor the li...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap