Brake test device for two-wheeled motorcycle

A two-wheeled motorcycle, braking test technology, applied in the direction of measuring device, vehicle test, machine/structural component test, etc., can solve the problems such as safety problems and performance test effects that cannot be completely solved, and improve the measurement accuracy and test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

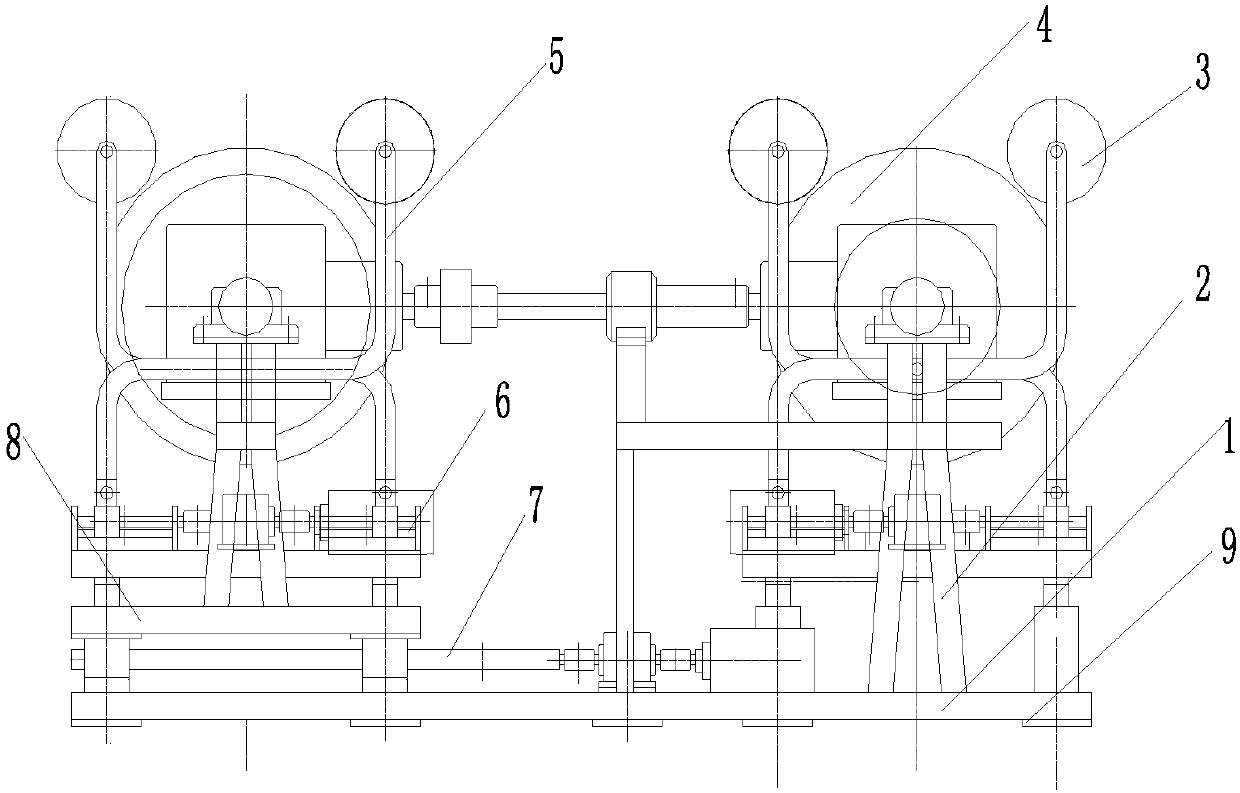

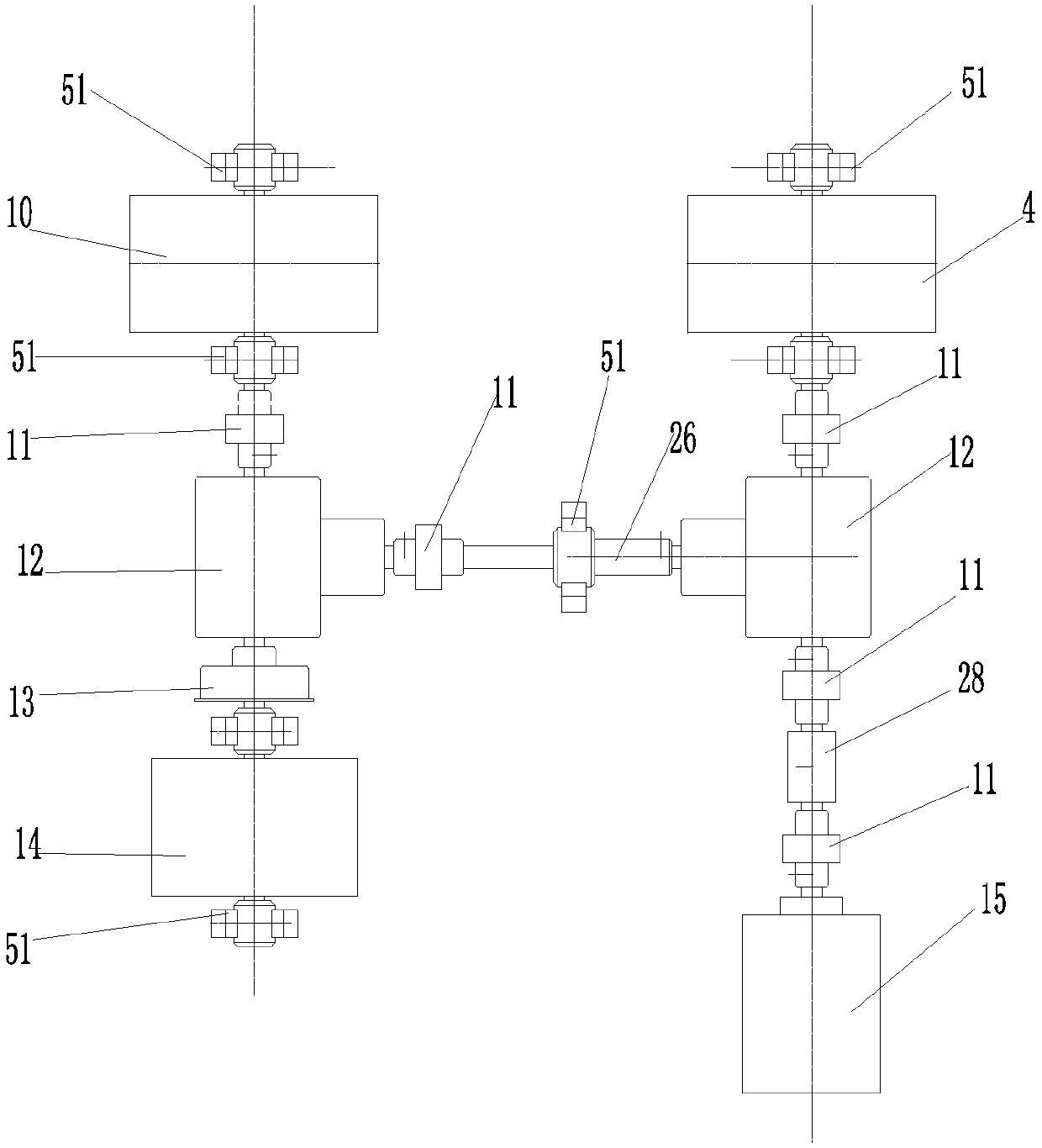

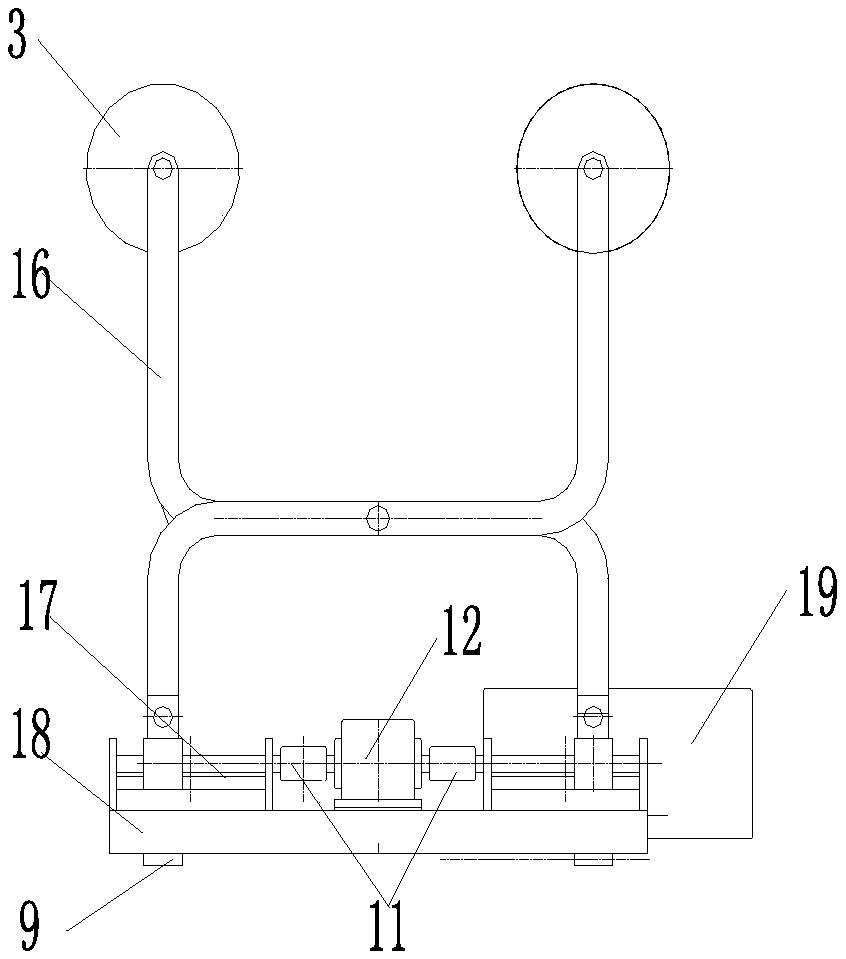

[0017] As an embodiment of the present invention, such as figure 1 , 2 , 3, 4, and 5, a two-wheeled motorcycle brake test device is characterized in that: it includes a main transmission system 8, a loading system 5, a wheelbase adjustment system, a chassis 1 and an electric control system, the main transmission The two front and rear rollers 10 and 4 of the system are connected in linkage through a telescopic transmission shaft. A motor is connected to one side of the rear roller in the length direction, an inertia roller is connected to the front roller in the length direction, and a frequency converter is connected to the motor shaft. Both sides of the front and rear rollers are respectively provided with auxiliary rollers 3 in the loading system. The front roller part in the main transmission system is installed on the wheelbase adjustment system 7, and the loading system is installed on the wheelbase adjustment system. The main transmission system The rotating speed torq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com