Food frying device

A technology of food oil and equipment, applied in the direction of oil/fat roasting, etc., can solve the problems of affecting work efficiency, slow processing speed, loss of processors, etc., and achieve the effect of improving frying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings.

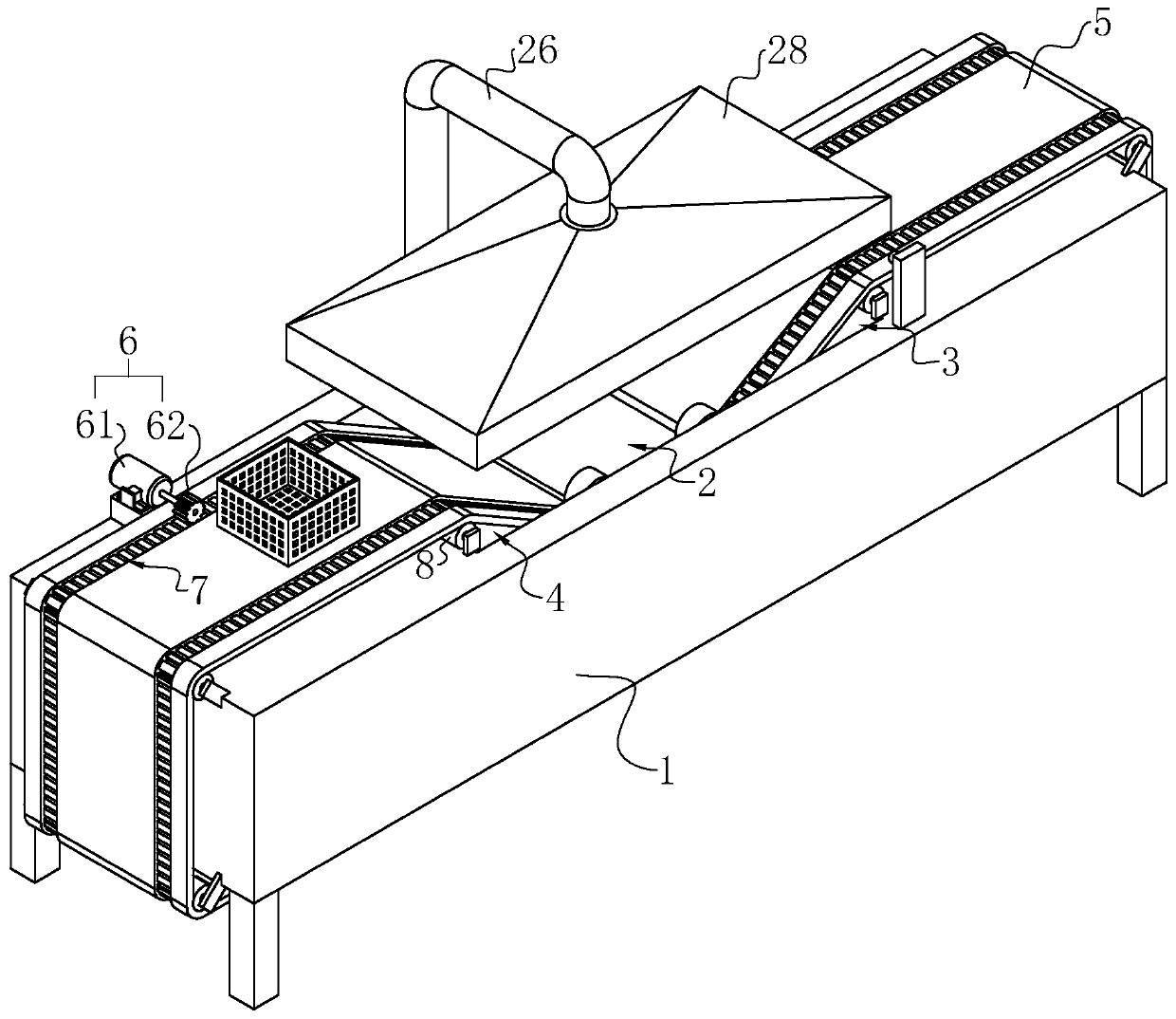

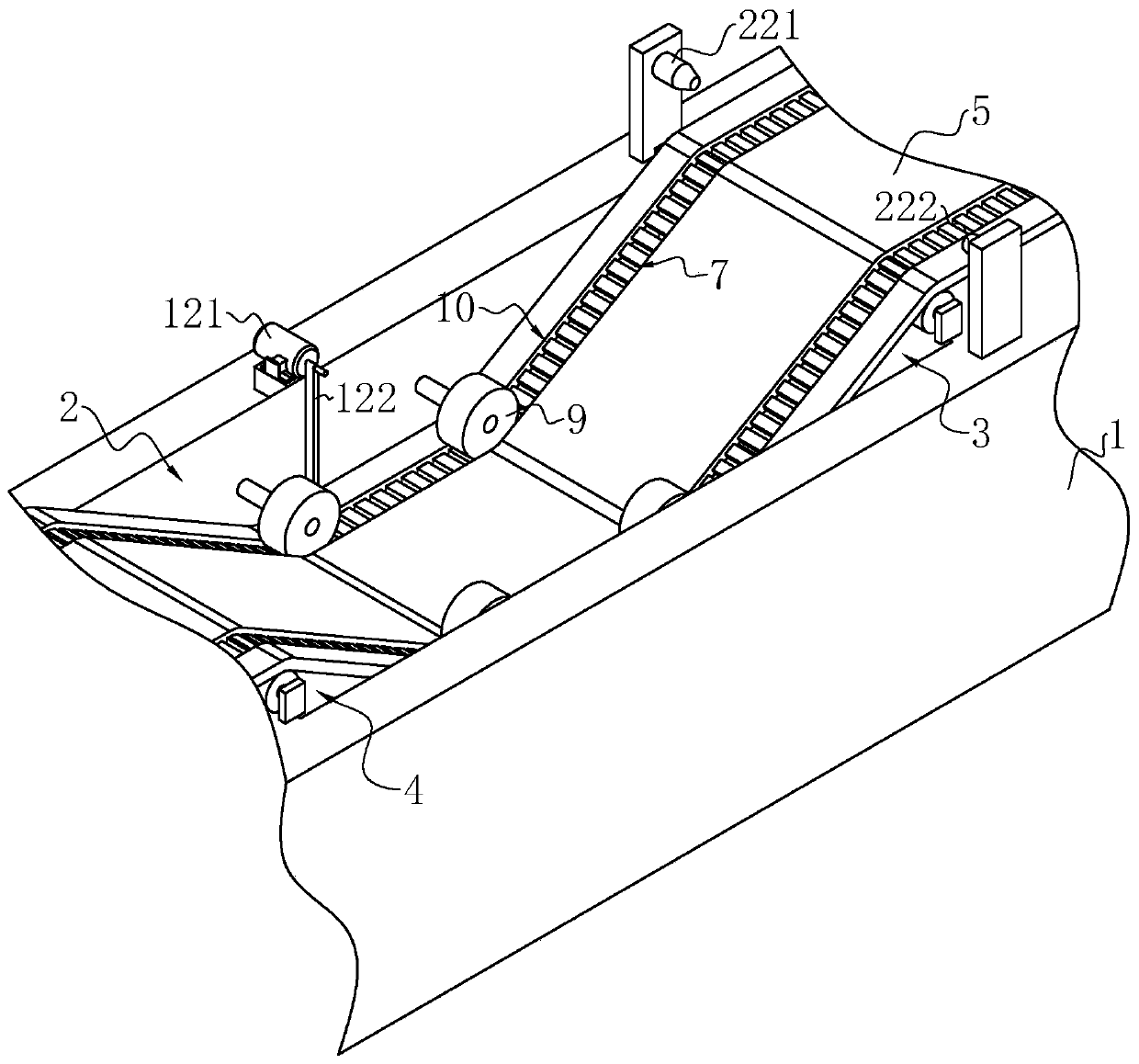

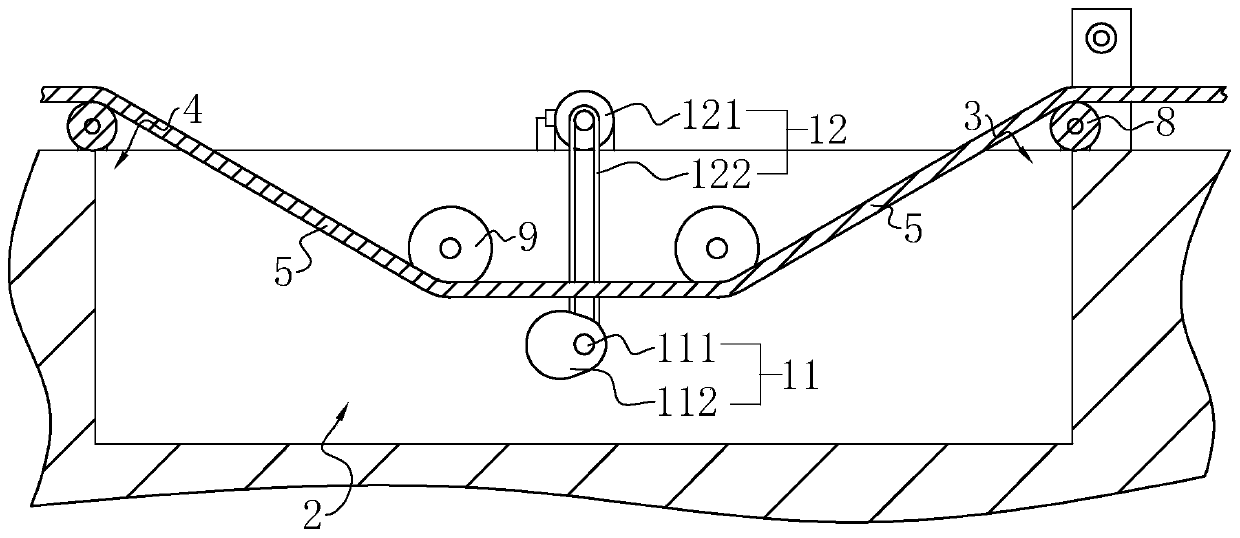

[0038] refer to figure 1 and figure 2 , a kind of food frying equipment, comprises body 1, and body 1 is provided with oil tank 2, and oil tank 2 is used for containing oil tank 2, and oil tank 2 is provided with input port 3 and output port 4. The body 1 is provided with a first heating assembly for heating the oil tank 2, and a temperature sensor is also provided in the oil tank 2, and the temperature sensor is electrically connected with the first heating assembly, so that the temperature in the oil tank 2 is kept within a preset range Inside.

[0039] refer to figure 1 and figure 2, the body 1 is provided with a conveyor belt 5, the conveyor belt 5 is used to drive the food into the oil tank 2 and leaves, the width direction of the conveyor belt 5 is parallel to the width direction of the oil tank 2, and the conveyor belt 5 along its width direction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com