Knife components and food processors

A knife assembly and knife technology, applied in the field of food cooking machines, can solve the problem that the knife and the knife shaft are difficult to take into account the convenience of disassembly and assembly, safety and reliability, etc., and achieve the effect of simple and convenient disassembly operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

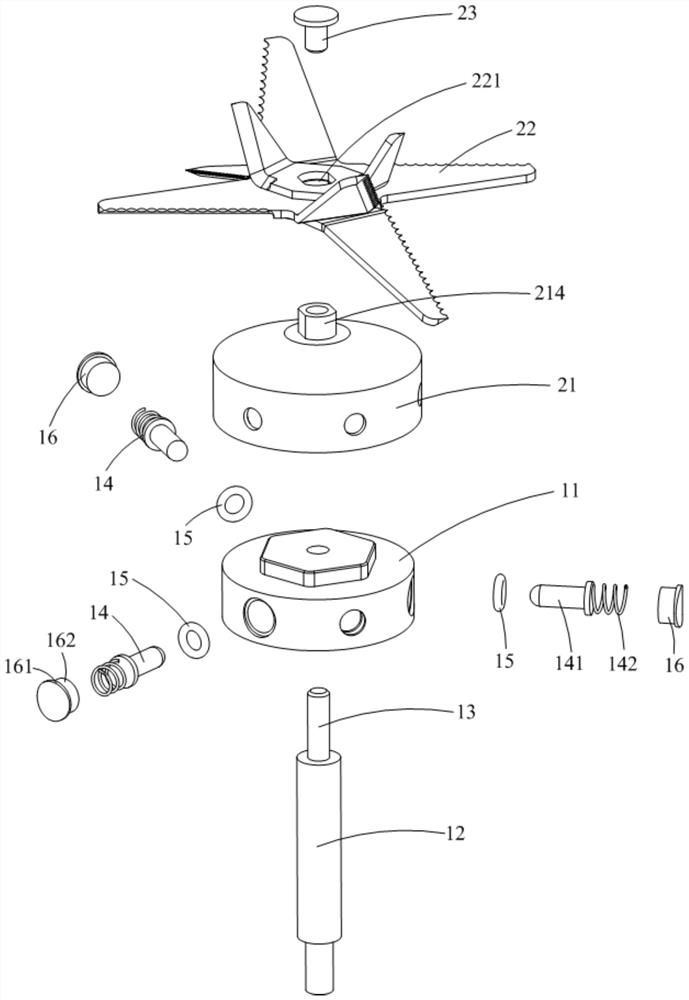

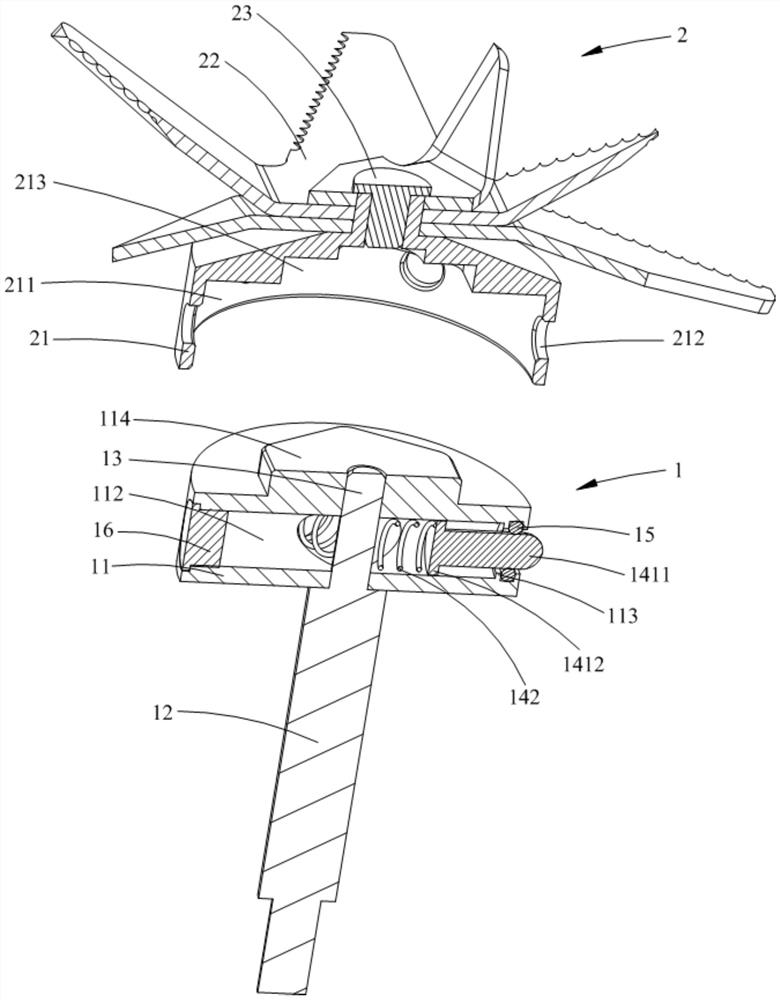

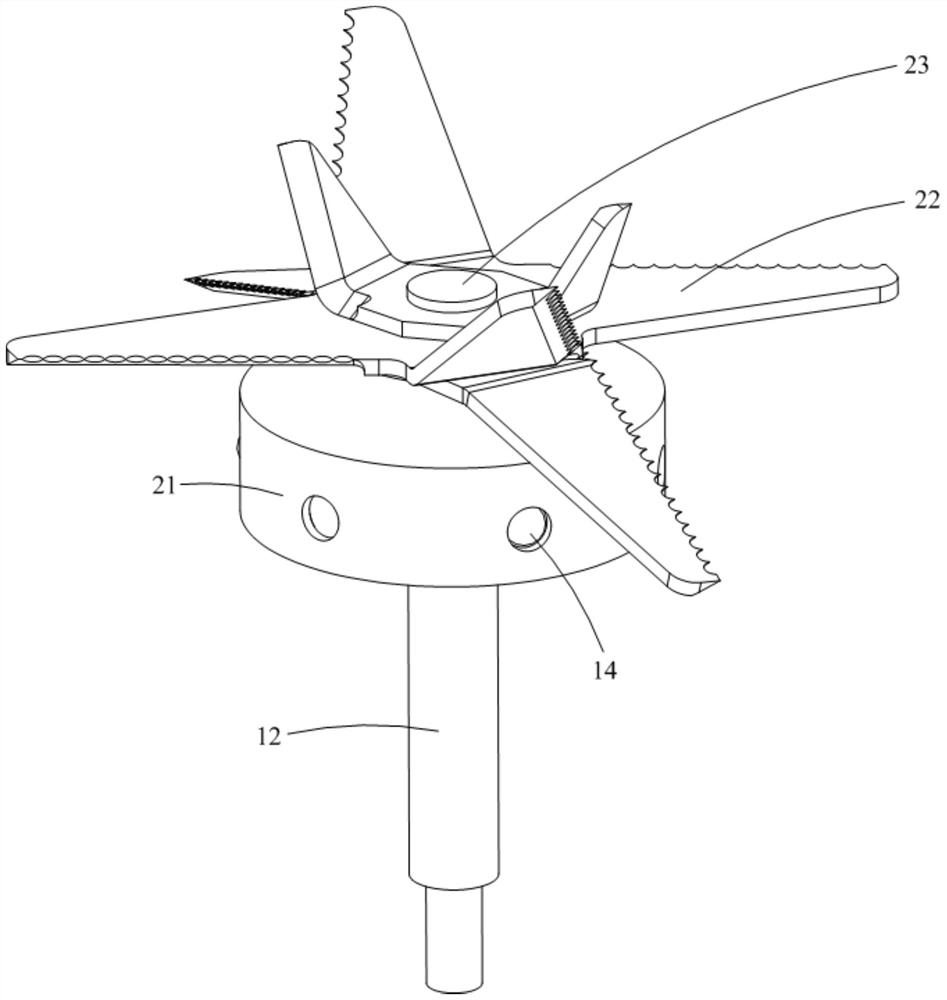

[0057] Such as Figure 1-9 As shown, the knife assembly 100 provided by Embodiment 1 of the present invention is used in a food cooking machine, and includes a knife shaft 1 and a knife 2 detachably mounted on the knife shaft 1. The bottom of the knife 2 is provided with a concave cavity 211, and the concave cavity 211 Positioning hole 212 is provided on the side wall; knife shaft 1 includes seat body 11, shaft body 12, support rod 13 and elastic member 14, seat body 11 is accommodated and positioned in concave cavity 211, shaft body 12 from seat body 11 The bottom extends downwards, the support rod 13 vertically passes through the connecting seat 201 body 11, and the elastic member 14 includes a positioning rod with one end arranged in the seat body 11 and the other end extending laterally out of the seat body 11 and inserted into the positioning hole 212 141 and two ends abut against the positioning rod 141 and the first elastic member 142 of the supporting rod 13 respective...

Embodiment 2

[0095] The main difference between the knife assembly 100 and the food cooking machine provided in this embodiment and the first embodiment is that the elastic member 14 is set differently, which is specifically reflected in: Figure 1-9 As shown, in Embodiment 1, the elastic member 14 only includes one elastic piece; Figure 10-12 As shown, in this embodiment, the elastic member 14 includes two elastic pieces. Specifically, in this embodiment, the elastic member 14 further includes a second elastic member 143 sheathed on the rod body 1411 , one end of the second elastic member 143 abuts against the convex cap 1412 , and the other end abuts against the shoulder 113 . In this embodiment, when the cutter assembly 100 is rotating, the positioning rod 141 can overcome the elastic force of the second elastic member 143 under the action of centrifugal force to compress the second elastic member 143 and protrude outward to increase the depth inserted into the positioning hole 212 a...

Embodiment 3

[0106] The main difference between the knife assembly 100 and the food cooking machine provided in this embodiment and the first and second embodiments is that the connection mode between the support rod 13 and the base body 11 is different, which is specifically reflected in: Figure 1-12 As shown, in Embodiment 1 and Embodiment 2, the support rod 13 realizes its locking connection with the seat body 11 through the cooperation of the external thread on it and the internal thread in the vertical mounting hole 111; Figure 13 As shown, in this embodiment, the nut 17 outside the vertical mounting hole 111 of the support rod 13 is locked and positioned on the base body 11 . Specifically, in this embodiment, the vertical mounting hole 111 is a light through hole, and the support rod 13 includes a main rod body 131 penetrating in the light through hole and a stud 132 passing through the light through hole from the top of the main rod body 131, The cutter shaft 1 also includes a nut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com