Quickly-assembled motorized floating barge and assembling method

A barge and maneuvering technology, applied to barges/flat-bottomed boats, ships, etc., can solve the problems of inflexible movement and single working conditions, and achieve the effects of reducing slapping, reliable connection, and flexible disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

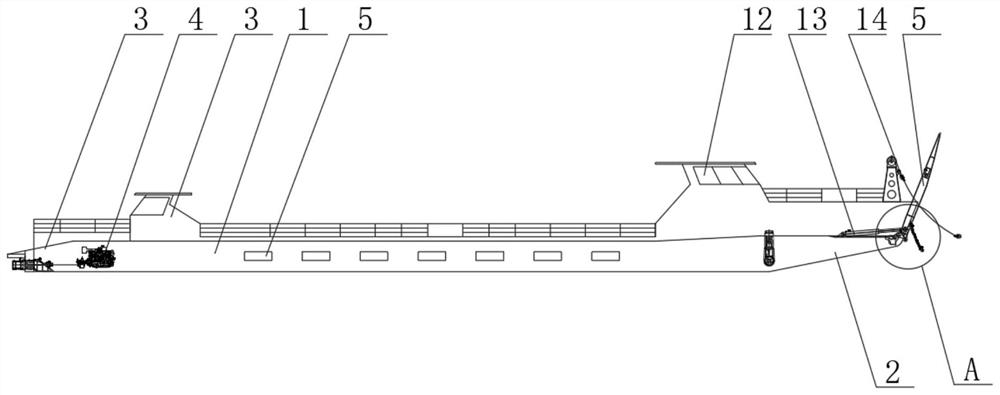

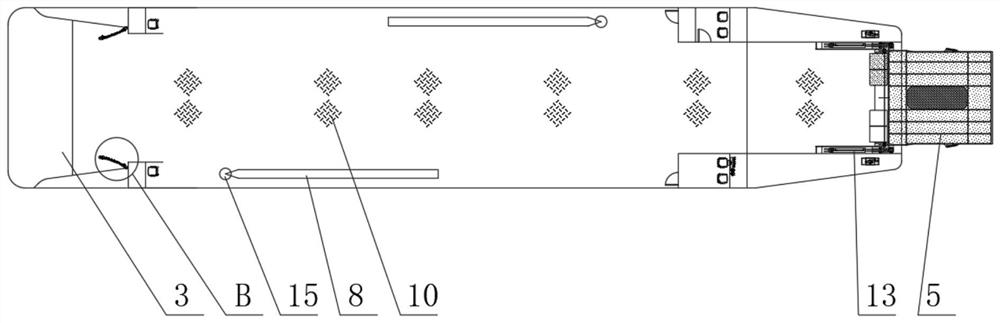

[0030] Such as Figure 1-Figure 4 As shown, the rapidly assembled mobile floating barge of this embodiment includes a barge body 1, the bow of the barge body 1 is provided with a wave splitting bow 2, and the tail of the barge body 1 is provided with a stern slide 3, and the wave splitting bow 2 and the stern The slideway 3 is matched and connected; the barge body 1 is provided with a power system 4 near the stern slideway 3, and the bow and stern of the barge body 1 are respectively provided with a cab and a control room 12,

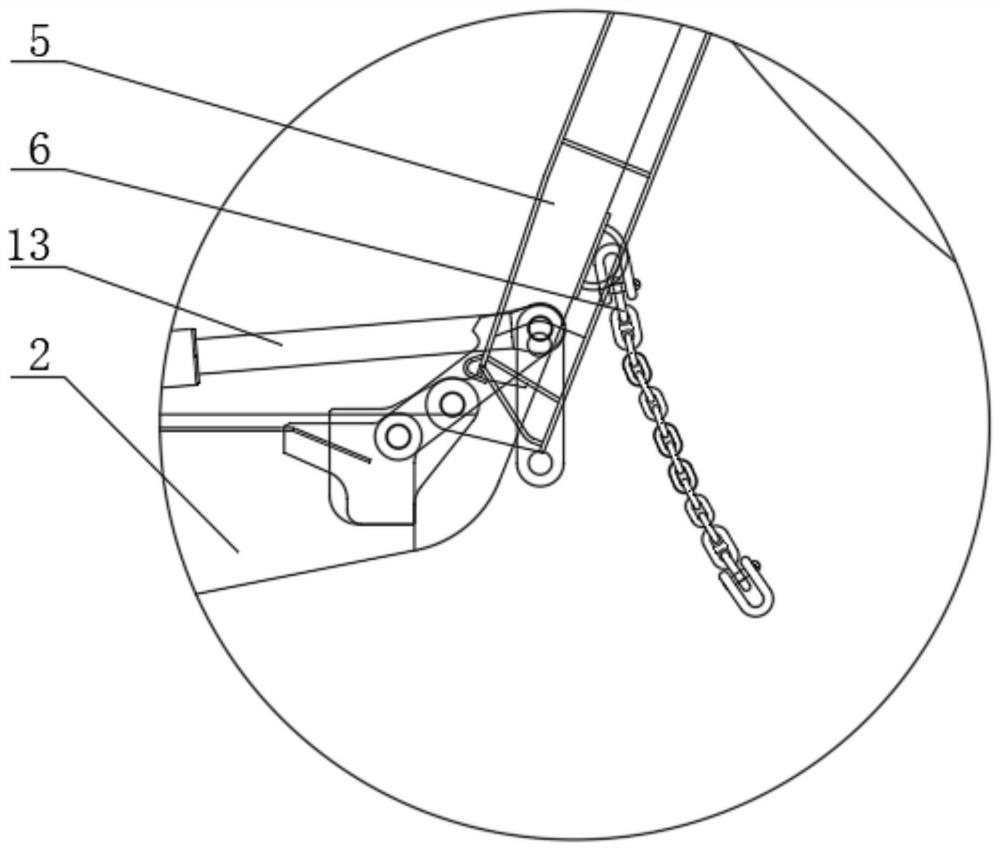

[0031] The wave splitting bow 2 is located at the bottom of the bow of the barge body 1, and the advancing direction end of the wave splitting bow 2 is rotatably connected with the bow ramp 5, and the bow ramp 5 is correspondingly provided with bow limit hinges 6,

[0032] The stern slideway 3 is located at the top...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com