Preparation device for barium sulfate in chemical tank workshop

A barium sulfate, chemical tank technology, applied in the direction of feeding device, calcium/strontium/barium sulfate, chemical instruments and methods, etc., can solve problems such as troublesome barium sulfate precipitation, difficult to collect barium sulfate precipitation, etc., to achieve convenient collection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

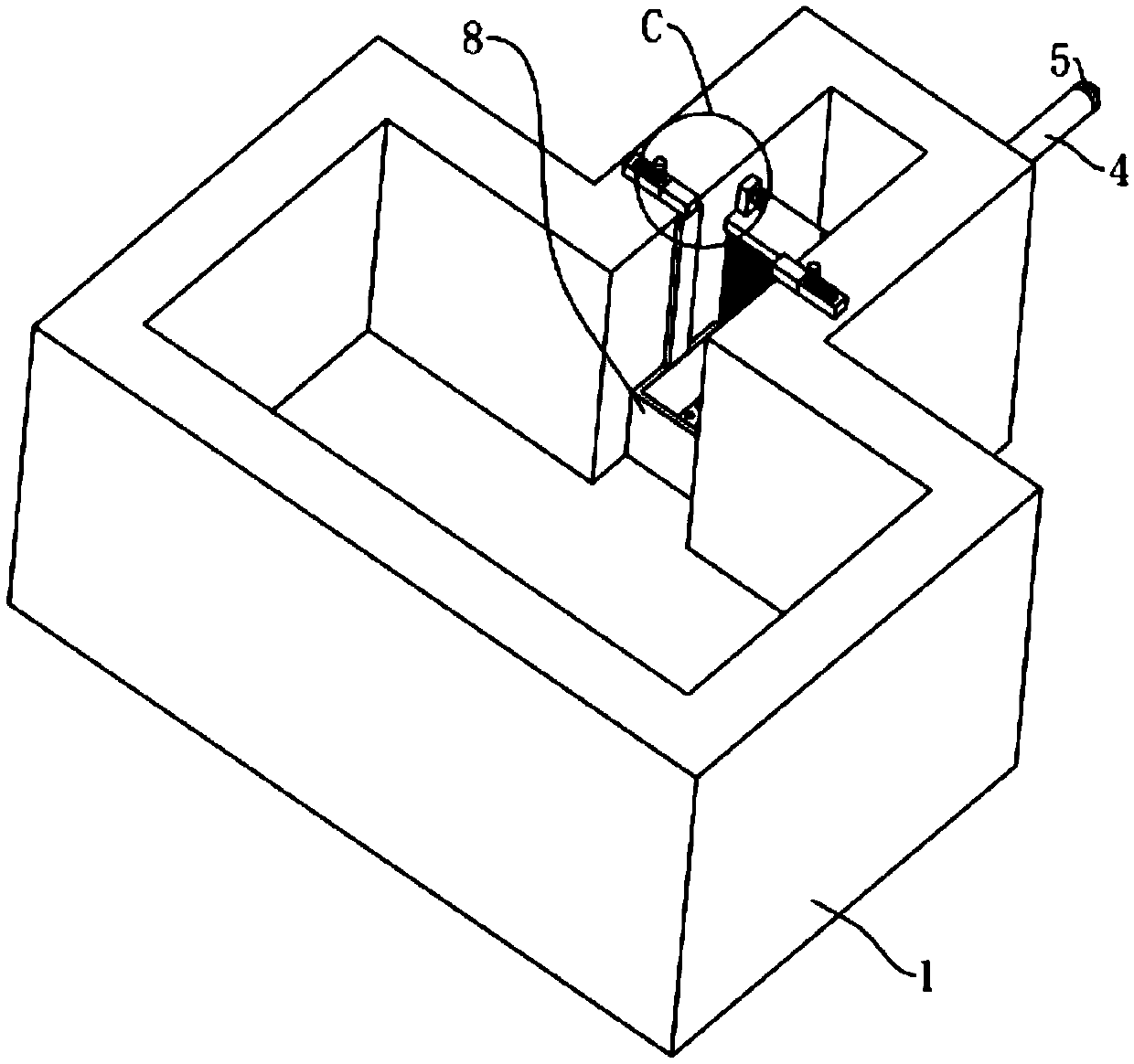

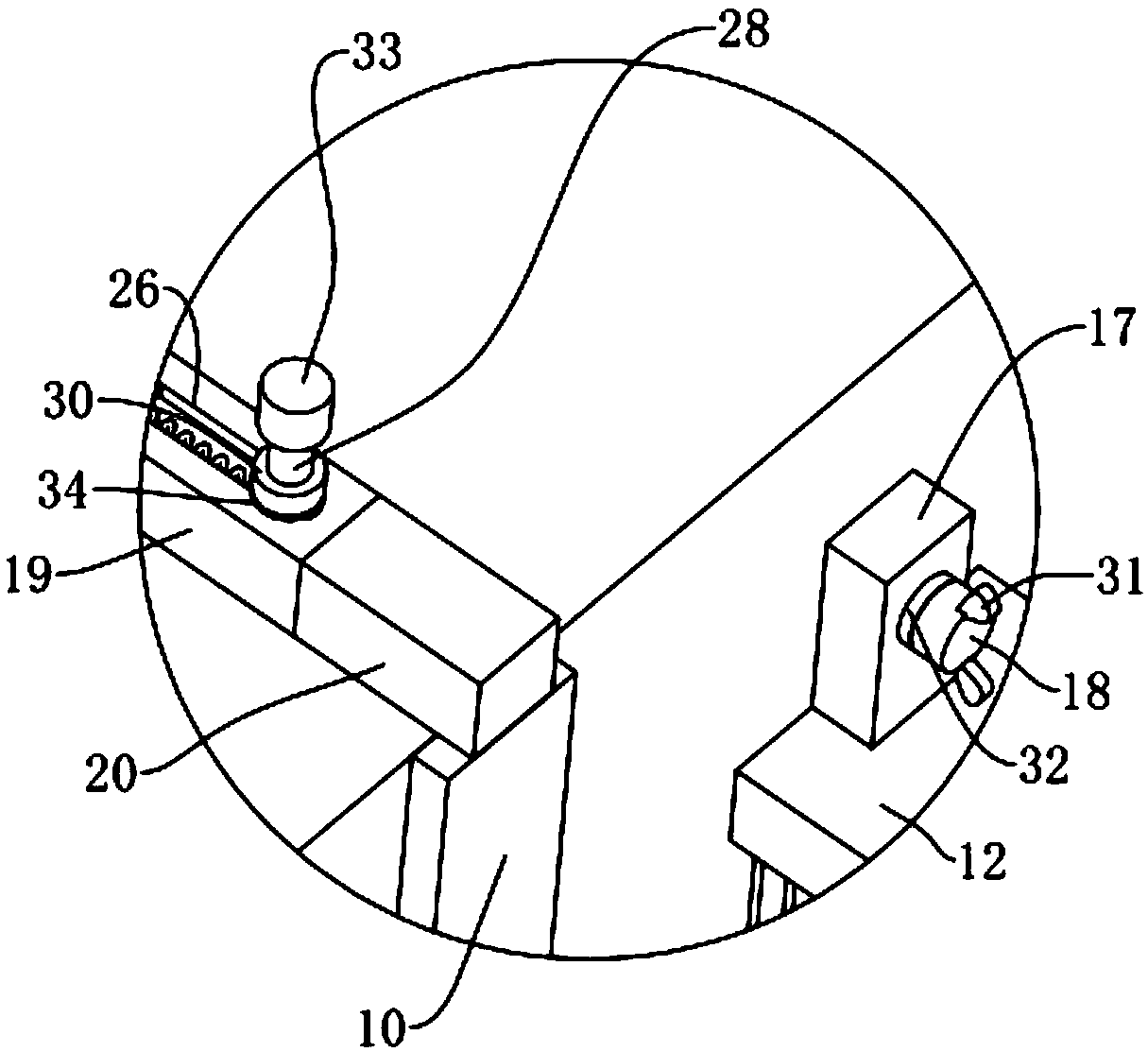

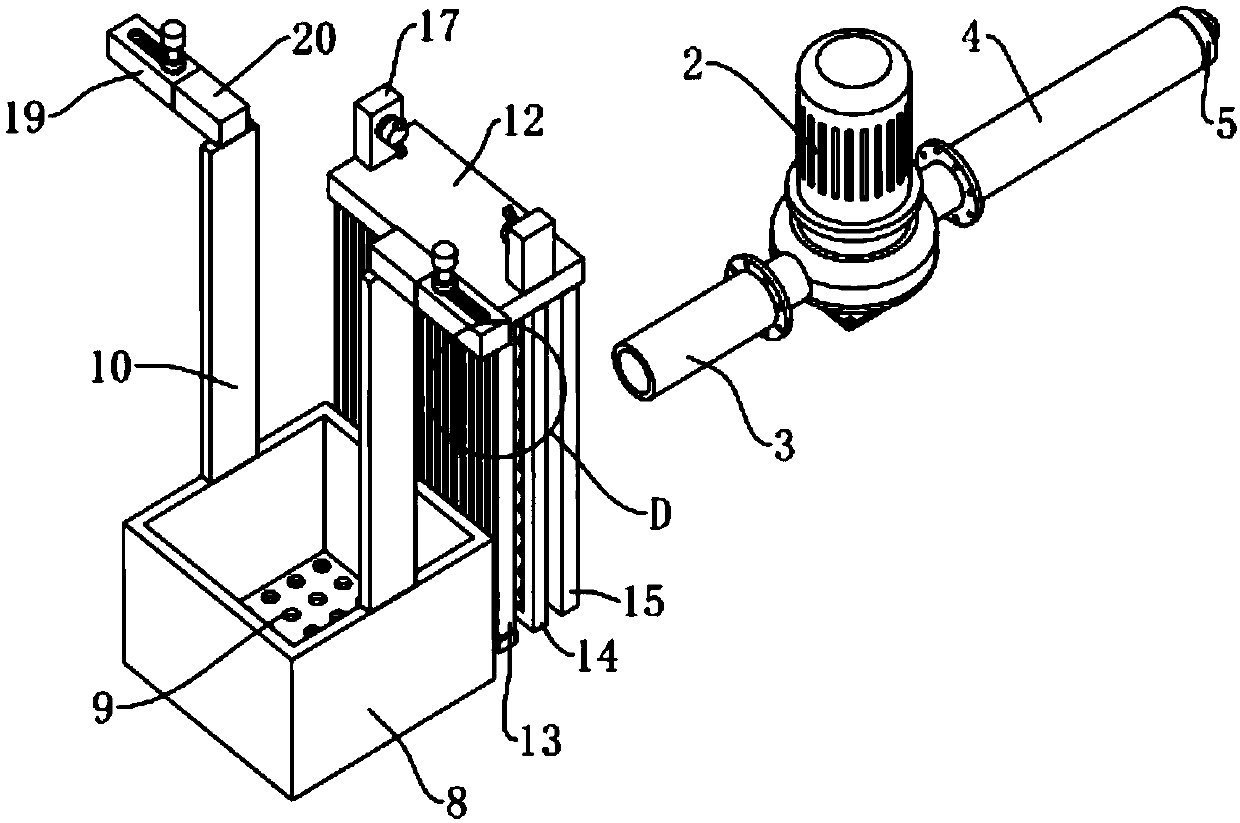

[0035] Such as Figure 1 to Figure 6 As shown, a barium sulfate production device in a chemical pool workshop includes a chemical pool 1 and a water pump 2 fixed on the outside of the chemical pool 1, wherein the shape of the chemical pool 1 is a convex shape, and the chemical pool 1 is a reaction pool. The liquid in the chemical tank 1 connects the water inlet of the water pump 2 with a first pipeline 3, and extends the first pipeline 3 into the chemical tank 1 at the end far away from the water pump 2, and connects the water outlet of the water pump 2 with a The second pipeline 4, and the end of the second pipeline 4 is threadedly connected with a blocking cover 5; in the chemical tank 1, a filter assembly is disassembled and connected with two sets of first locking parts, and a collection device is also arranged in the chemical tank 1 Box 8, collecting box 8 is used for collecting barium sulfate precipitation, and offers the first through hole 9 of densely dotted circle in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com