Single lamp indicating type winding mechanism and magnet adsorbing thread residue wire coil winding method

A winding mechanism and indication technology, which is applied in the direction of conveying filamentous materials, thin material handling, transportation and packaging, etc., can solve laborious problems, achieve convenient removal of wire coils, good reliability, and is not easy to scatter wire coils Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

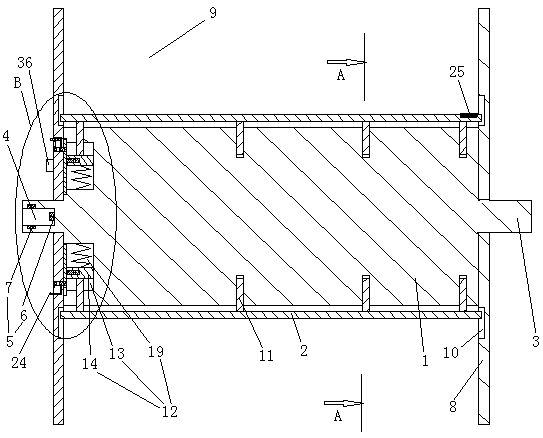

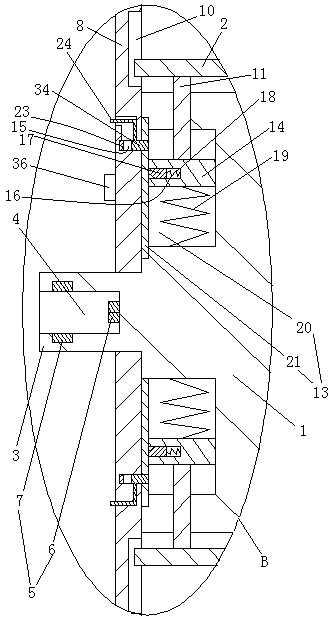

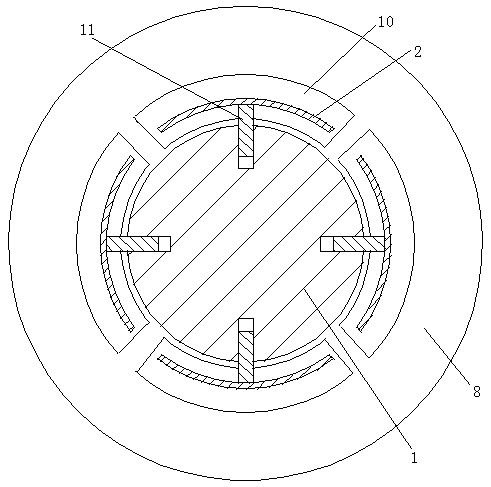

[0022] Embodiment one, see figure 1 , figure 2 , image 3 and Figure 4 , a single-light indicating winding mechanism, including a rotating shaft 1 and a number of winding rods 2 located on the periphery of the rotating shaft and extending axially along the circumferential direction of the rotating shaft. Specifically, there are 4 winding rods. Both ends of the rotating shaft are provided with shaft heads 3 . A counterbore 4 coaxial with the shaft head is provided on the end face of the shaft head. A power introduction structure 5 is arranged inside the counterbore 4 . The power introduction structure includes a conductive block 6 arranged on the bottom wall of the counterbore and a conductive ring 7 arranged on the peripheral wall of the counterbore and extending along the circumferential direction of the counterbore. End plates 8 are provided at both ends of the rotating shaft. The end plate is sleeved on the shaft head. Both end plates are detachably connected toge...

Embodiment 2

[0024] Embodiment two, the difference with embodiment one is:

[0025] see Figure 5 . The power introduction structure also includes an insulating plug 26 that is rotatably connected in the counterbore, a first conductive head 27 that abuts against the conductive block on the end surface of the insulating plug, and a conductive head installation hole 28 that is arranged on the peripheral surface of the insulating plug. And the second conductive head 29 pierced in the conductive head installation hole. A third conductive head 30 and a conductive spring 31 that drives the second conductive head to abut against the conductive ring are arranged in the conductive head installation hole. The conductive spring is electrically connected with the second conductive head and the third conductive head. The first conductive head is connected with a first power line 32 , and the third conductive head is connected with a second power line 33 . When in use, the first power line and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com