Canal bottom lining machine with herringbone two-way concrete scraper mechanism

A herringbone and concrete technology, applied in artificial waterways, water conservancy projects, buildings, etc., can solve problems such as large space occupation, unsuitable use, and complex structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

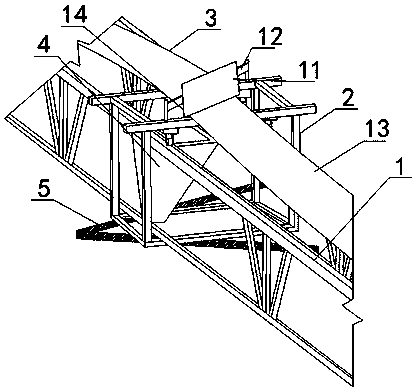

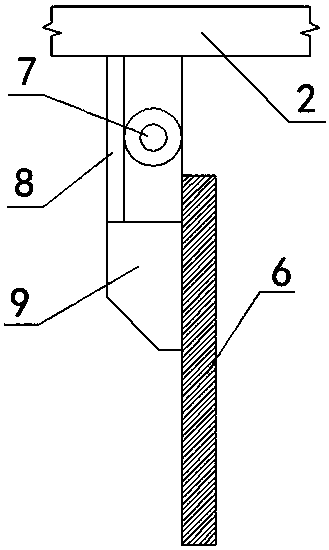

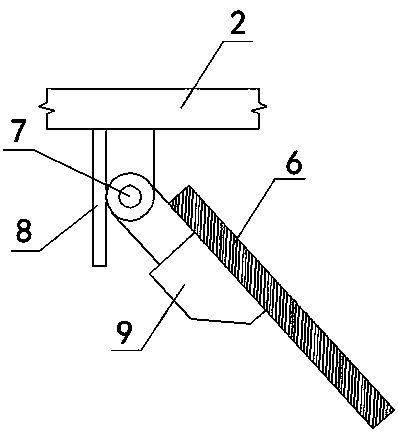

[0023] The first embodiment, such as figure 1 , figure 2 , image 3 and Figure 4 Shown: a trench bottom lining machine with a herringbone bidirectional concrete scraper mechanism, which includes: a truss 1, a paving trolley 2 arranged on the truss 1 and a conveying device 3 arranged on the top of the truss 1, It also includes a scraper mechanism 5 and a lower hopper 4 arranged on the paving trolley 2, and the feeding port of the lower hopper 4 is arranged at the output end 14 of the conveying device 3; the scraper mechanism 5 includes a scraper Plate 6, hinge 7, upper stopper 8 and lower stopper 9, the scraper 6 is arranged at the bottom of the paving trolley 2 through the hinge 7, and the upper stopper 8 is arranged at the hinge 7. The upper part of the outer side, the lower block 9 is arranged on the lower part of the outer side of the hinge 7, the upper block 8 and the lower block 9 can be rotated and abutted outward according to the hinge 7, and the scraper There are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com