Low alloy steel and cast steel combination cable clamp

A low-alloy steel and cast steel technology, applied in the field of low-alloy steel and cast steel combined cable clamps, can solve the problems of high casting difficulty, low reliability, complex shape, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

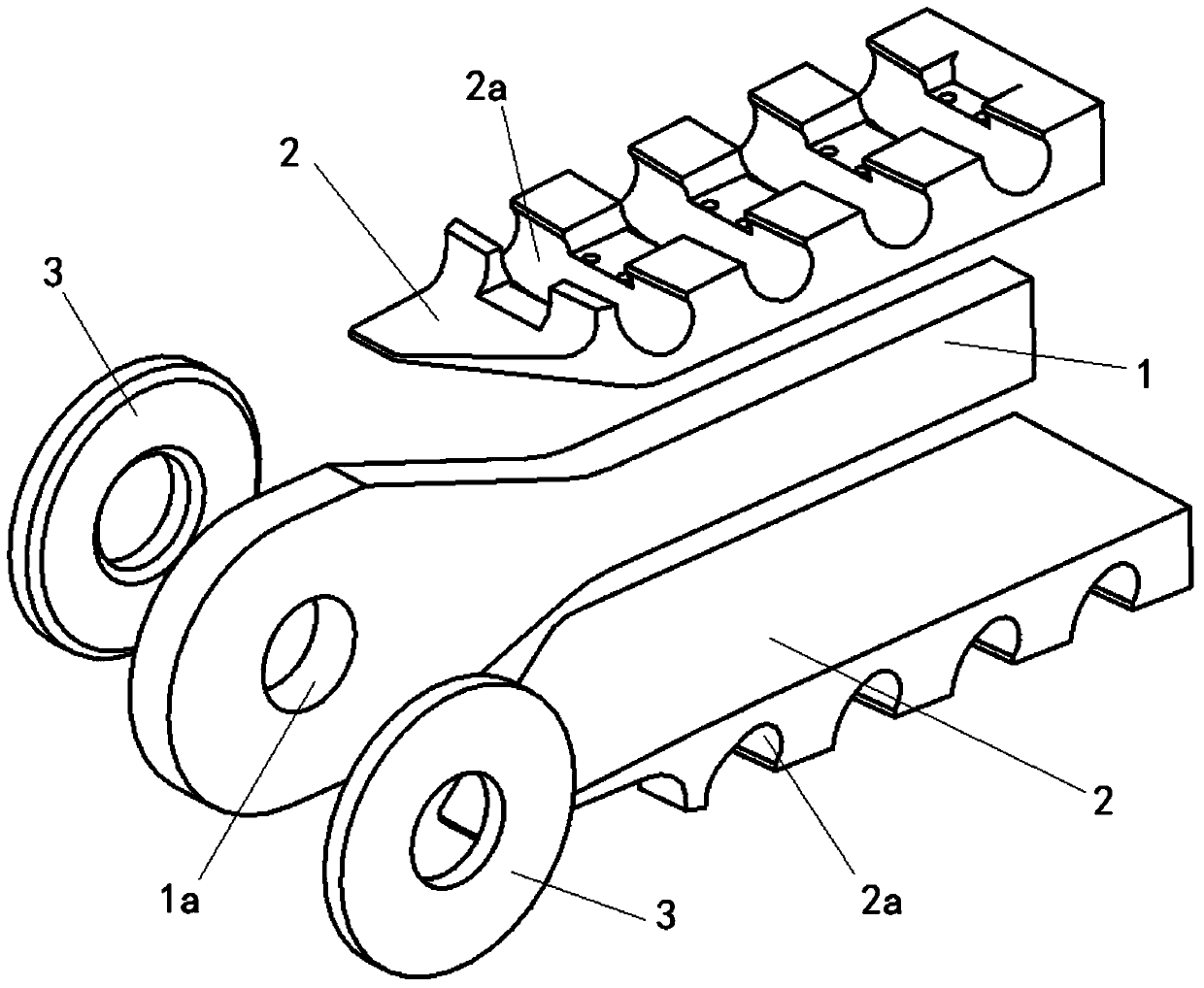

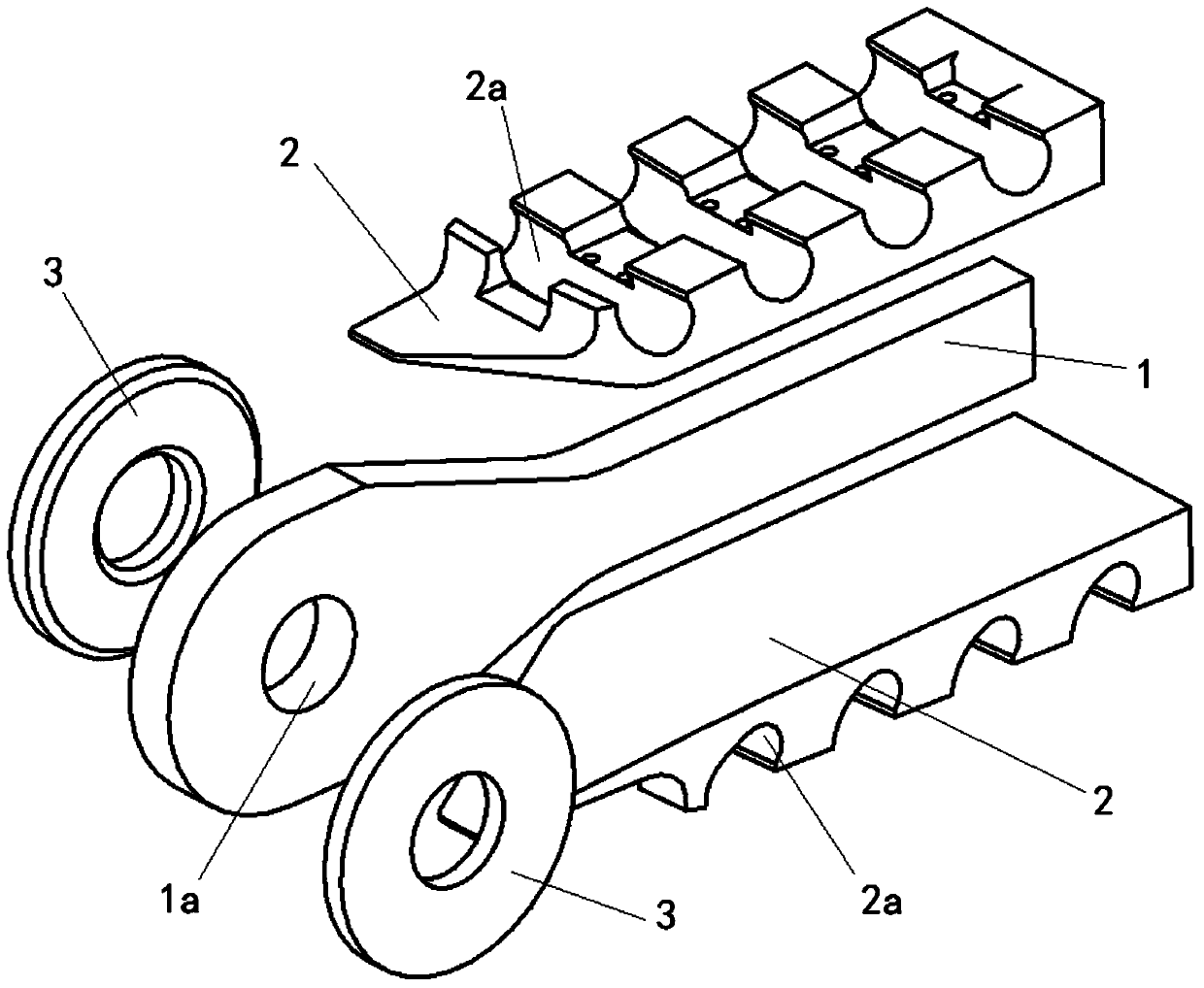

[0022] figure 1 A specific embodiment of the low-alloy steel and cast steel composite cable clamp of the present application is shown, which is used to connect the radial cable and the hoop cable of the spoke-type single-layer cable net. The same as the traditional cable clamp, the The cable clamp also includes a radial cable connecting lug plate 1 with a radial cable connecting hole 1a and a hoop cable groove seat 2 with a plurality of hoop cable positioning grooves 2a. In actual application, the radial cable in the cable net structure is connected with the radial cable connecting hole 1a of the radial cable connecting lug plate 1, and the hoop cable is inserted into the hoop cable positioning groove 2a of the hoop cable groove seat 2. The hoop cable is compressed and fixed by means of a pressure plate (not shown in the figure), and the aforementioned pressure plate is locked and fixed with the hoop cable groove seat 2 by bolts.

[0023] The key improvement of this embodiment i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com