Asymmetric inerter

An inertial container and asymmetric technology, applied in the field of asymmetric inertial containers, can solve the problems of increasing use cost, not conforming to the development theme, energy loss, etc., and achieve the effect of avoiding impact, good stability, and safe and reliable driving environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

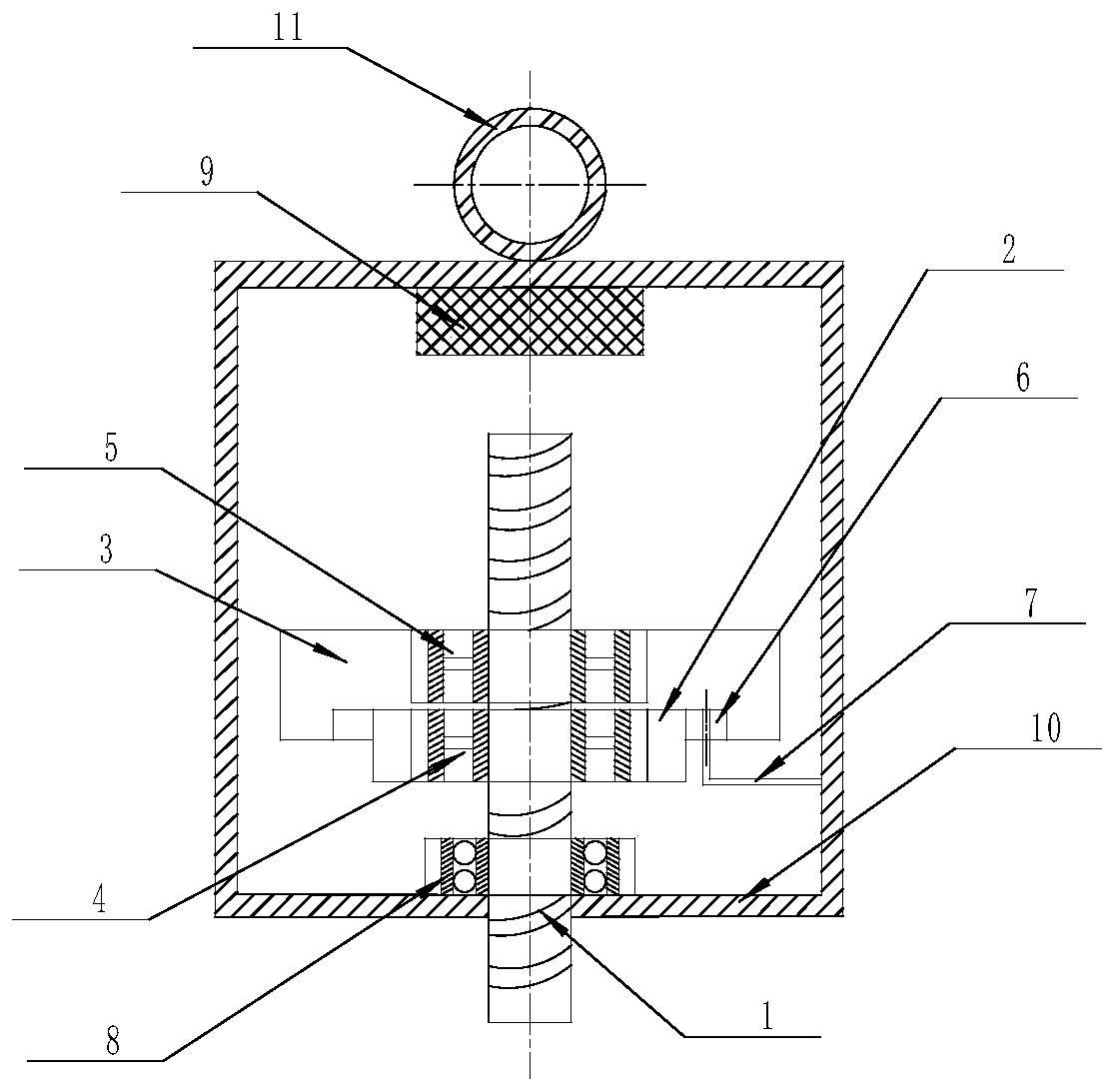

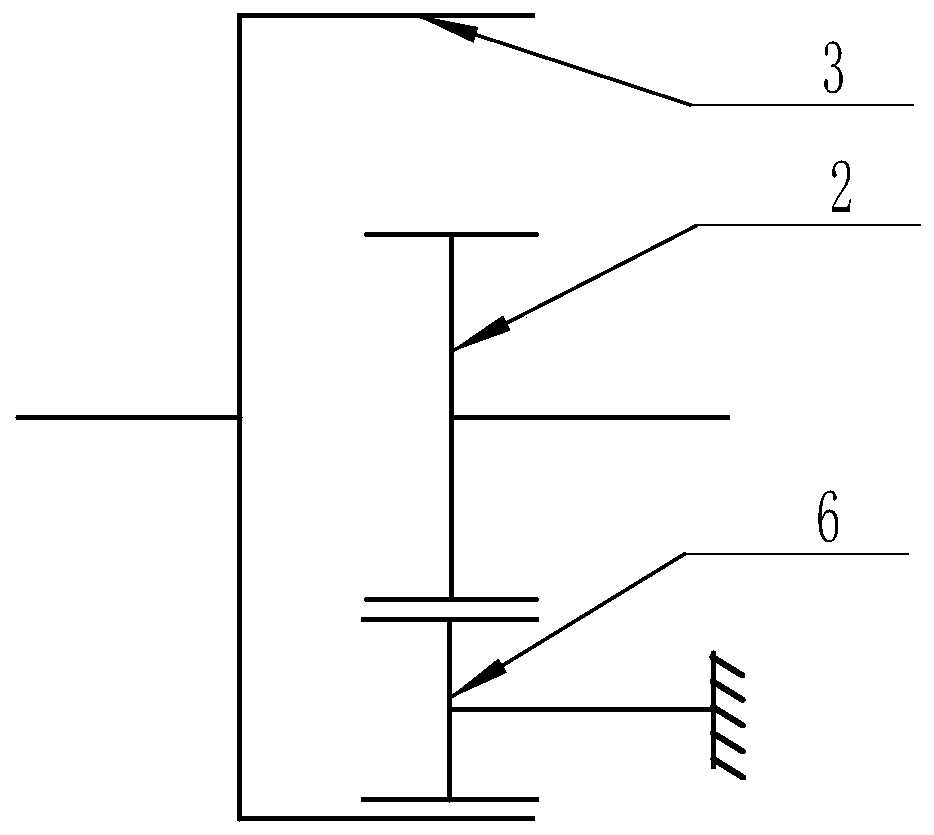

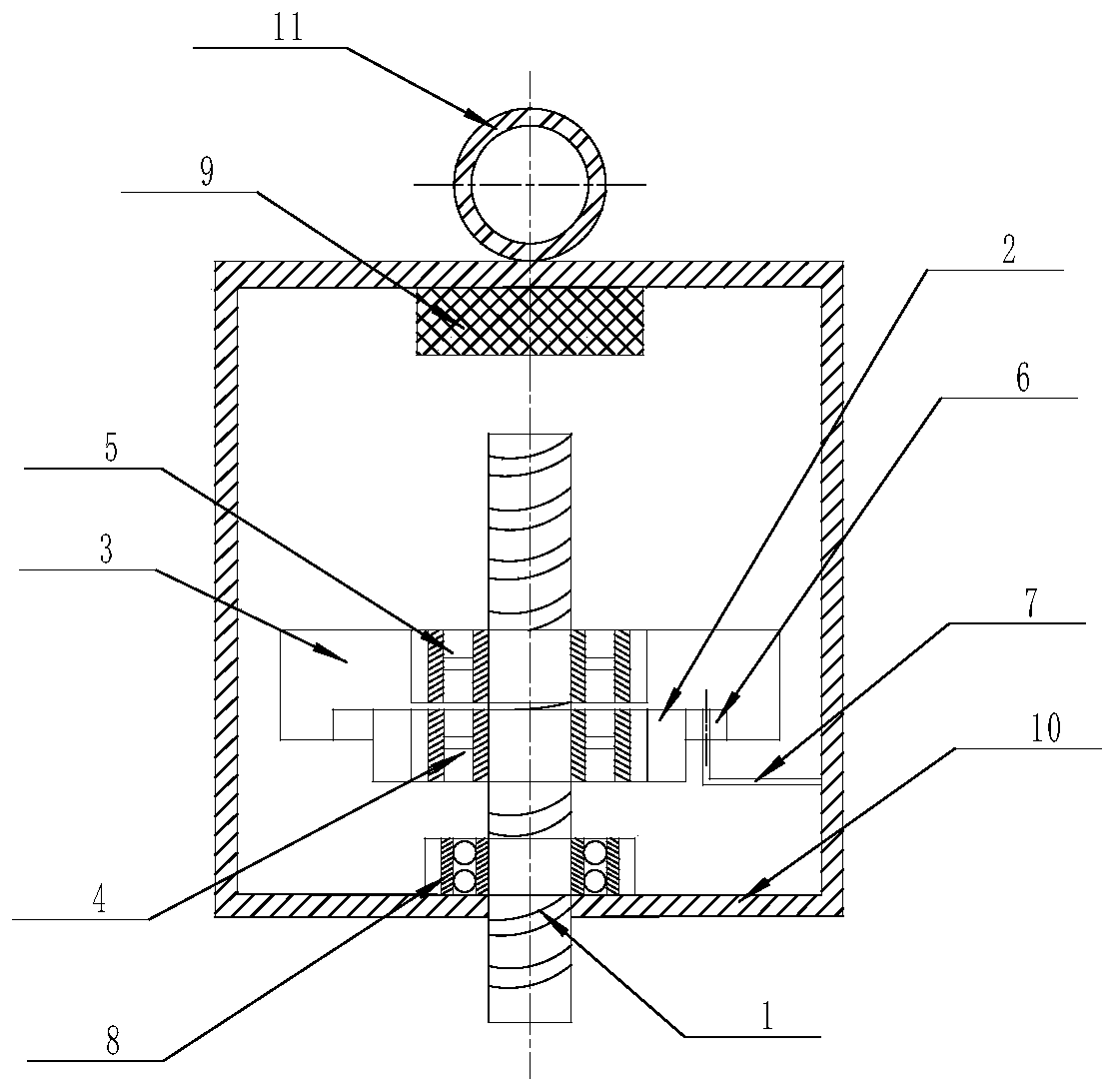

[0027] Such as figure 1 As shown, the asymmetric inerter of the present invention includes a ball screw 1 , a main gear 2 , a flywheel 3 , a lower ratchet 4 , an upper ratchet 5 and a housing 10 .

[0028] The ball screw 1 is connected to the casing 10 through the bearing 8, and one end of the ball screw 1 protrudes from the casing 10 to connect with the wheel, and the casing 10 is fixedly connected with a lifting lug 11, and the lifting lug 11 is connected to the vehicle body , the housing 10 is also installed with a limit block 9 to prevent the other end of the ball screw 1 inside the housing 10 from colliding with the inside of the housing 10 .

[0029] The ball screw 1 is also equipped with a lower ratchet 4 and an upper ratchet 5, the inner ring of the upper ratchet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com