An oil deflector ring structure

A technology of oil deflecting ring and oil seal, which is applied in the direction of engine sealing, mechanical equipment, engine components, etc., can solve problems such as leakage, achieve the effects of improving sealing effect, preventing lubricating oil leakage, and reducing the risk of radial friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

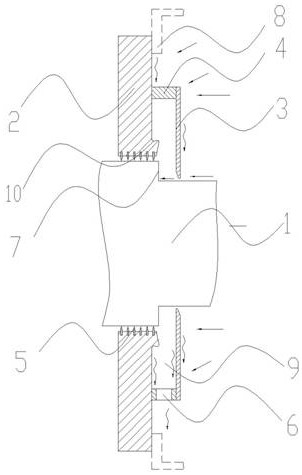

[0030] An oil slinger structure in this embodiment includes an oil slinger 2, a rotor 1, a pre-baffle 3 and a mounting ring 4;

[0031] Both the oil deflector ring 2 and the pre-baffle plate 3 are annular structures, and the rotor 1 passes through the inner holes of the oil deflector ring 2 and the pre-baffle plate 3;

[0032] The pre-baffle 3 is located inside the oil slinger 2, and the pre-baffle 3 and the oil slinger 2 are connected by a mounting ring 4;

[0033] The oil deflector ring 2 is provided with a plurality of oil seal teeth 5 near the rotor 1;

[0034] The inner diameter of the pre-baffle 3 is smaller than the diameter of the oil seal teeth 5 , the diameter of the rotor 1 at the pre-baffle 3 is smaller than the diameter of the rotor 1 at the oil seal teeth 5 , and the diameter difference of the rotor 1 forms a boss 7 .

[0035] Preferably, the inner diameter of the pre-baffle plate 3 is smaller than the diameter of the rotor 1 at the oil seal teeth 5 .

[0036] ...

Embodiment 2

[0044] An oil slinger structure in this embodiment includes an oil slinger 2, a rotor 1, a pre-baffle 3 and a mounting ring 4;

[0045] Both the oil deflector ring 2 and the pre-baffle plate 3 are annular structures, and the rotor 1 passes through the inner holes of the oil deflector ring 2 and the pre-baffle plate 3;

[0046] The pre-baffle 3 is located inside the oil slinger 2, and the pre-baffle 3 and the oil slinger 2 are connected by a mounting ring 4;

[0047] The oil deflector ring 2 is provided with a plurality of oil seal teeth 5 near the rotor 1;

[0048] The inner diameter of the pre-baffle 3 is smaller than the diameter of the oil seal teeth 5 , the diameter of the rotor 1 at the pre-baffle 3 is smaller than the diameter of the rotor 1 at the oil seal teeth 5 , and the diameter difference of the rotor 1 forms a boss 7 .

[0049] Preferably, the inner diameter of the pre-baffle plate 3 is smaller than the diameter of the rotor 1 at the oil seal teeth 5 .

[0050] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com