Pipeline Space Dimension Measurement System

A space size and measurement system technology, applied in the direction of measuring devices, instruments, optical devices, etc., can solve the problems of low measurement efficiency and high technical requirements for measurement personnel, and achieve the effect of low manual operation requirements, high measurement efficiency and accurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

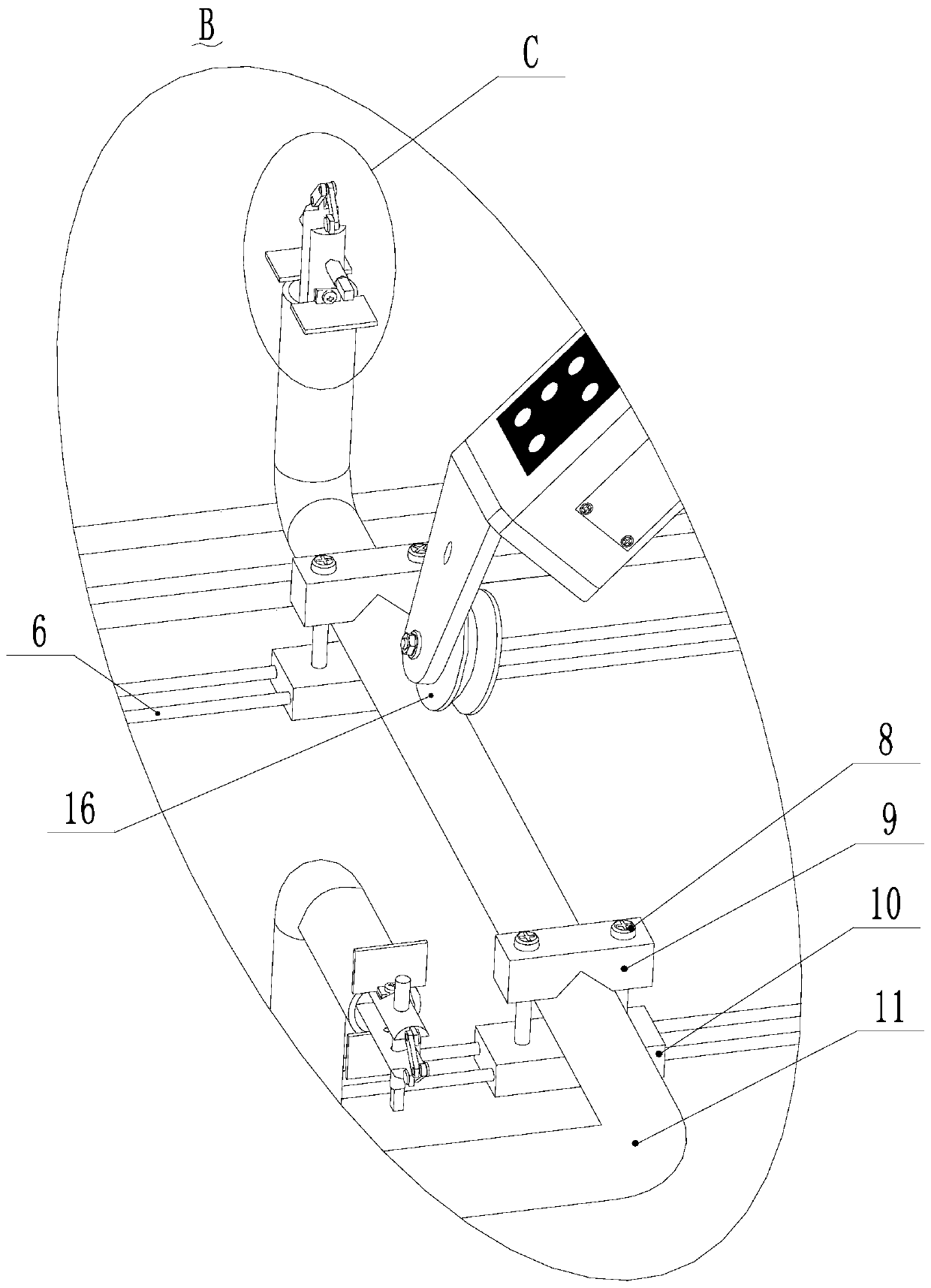

[0044] See figure 1 , image 3 , Figure 5 and Figure 6 , as a specific implementation of the pipeline space size measurement system provided by the present invention, the measuring instrument body is provided with an accommodation space, and the identification component includes a luminous body 20 arranged in the accommodation space, a power supply and a mask with a light exit hole. The diaphragm 22 and the mask 22 are installed on the measuring instrument body, and the power supply is electrically connected with the illuminant.

[0045] The mask plate 22 is an optical mask plate made by a photolithography mechanism, which has an optical light exit hole, and the outgoing light of the illuminant 20 can pass through the light exit hole of the mask plate 22 to form a target of a certain shape, so that the size capture analysis device can capture The trajectory of the target is identified and then analyzed to obtain the spatial size of the bent pipe 11 to be tested.

[0046]...

specific Embodiment approach

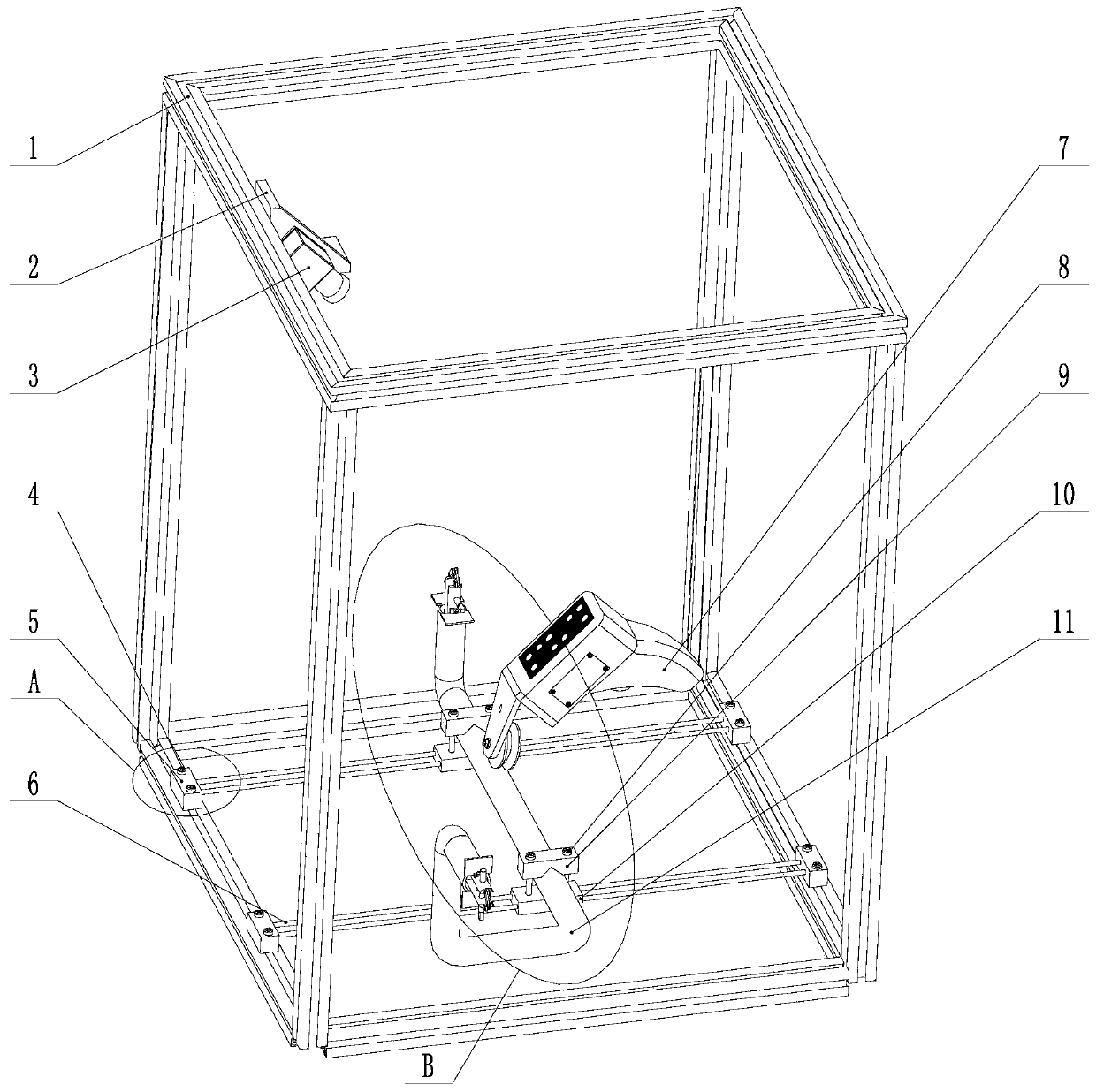

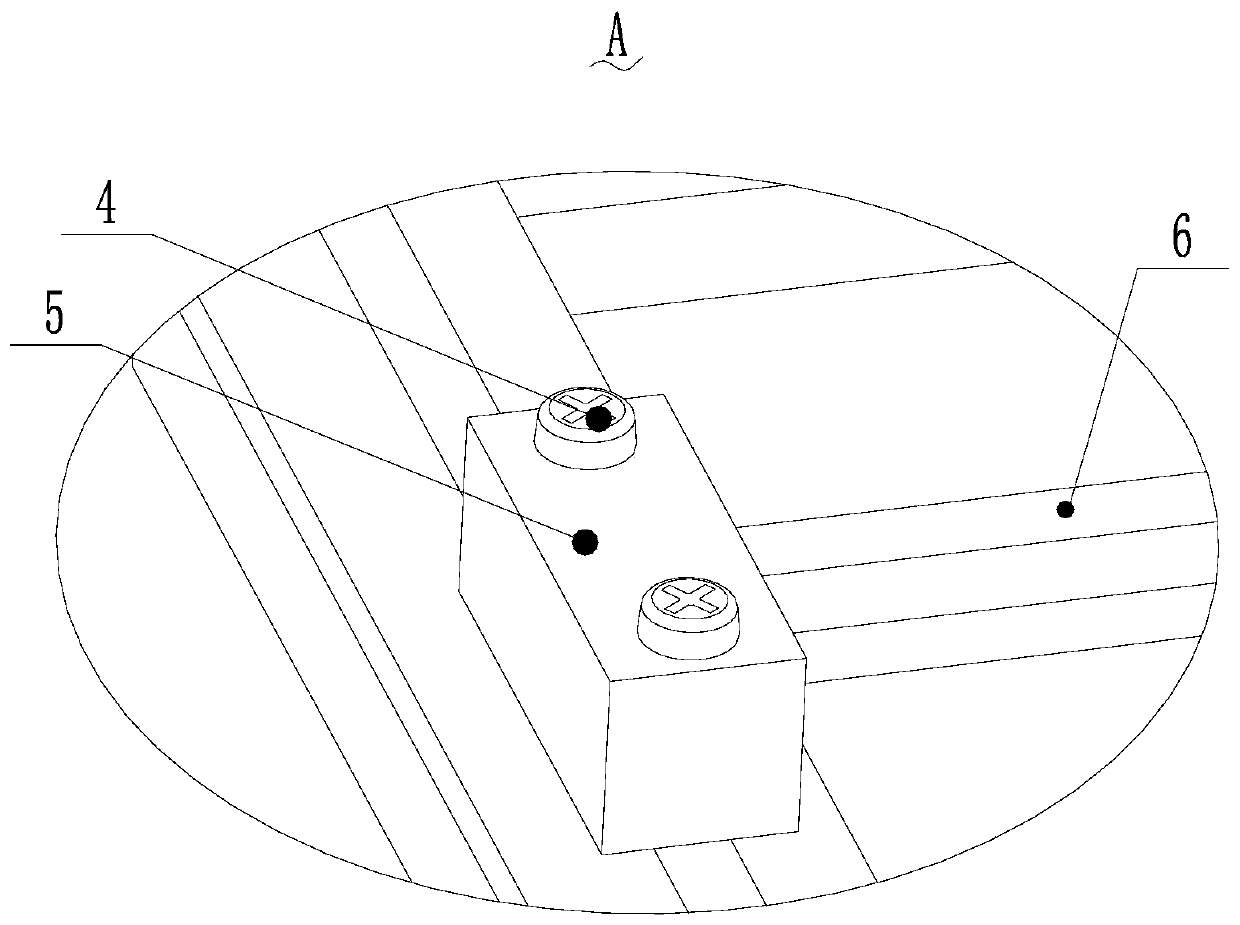

[0054] See Figure 1 to Figure 3 , as a specific implementation of the pipeline space dimension measurement system provided by the present invention, the fixing assembly includes a first slider 5 that can be adjusted laterally on the frame 1, a second slider that can be adjusted longitudinally relative to the first slider 5 The second slide block 10 and the fixing piece arranged on the second slide block 10 and used for fixing the measured bent pipe. Like this, by adjusting the first slide block 5 can make the fixed part carry out lateral position adjustment relative to the frame 1, by adjusting the second slide block 10 can make the fixed part carry out longitudinal position adjustment relative to the frame 1, so just can make the fixed part have The function of multi-degree-of-freedom adjustment is adapted to the requirements of fixing bent pipes 11 of different sizes and shapes.

[0055] See Figure 1 to Figure 3 , as a specific implementation of the pipeline space size m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com