Wiring rapid pressing tool and storage battery line rapid replacing device comprising same

A battery wire and tooling technology, applied in the direction of connection where permanent deformation works, can solve the problems of grounding, lack of protection devices, high damage rate, and achieve the effects of not easy safety accidents, quick installation and disassembly, and not easy to damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

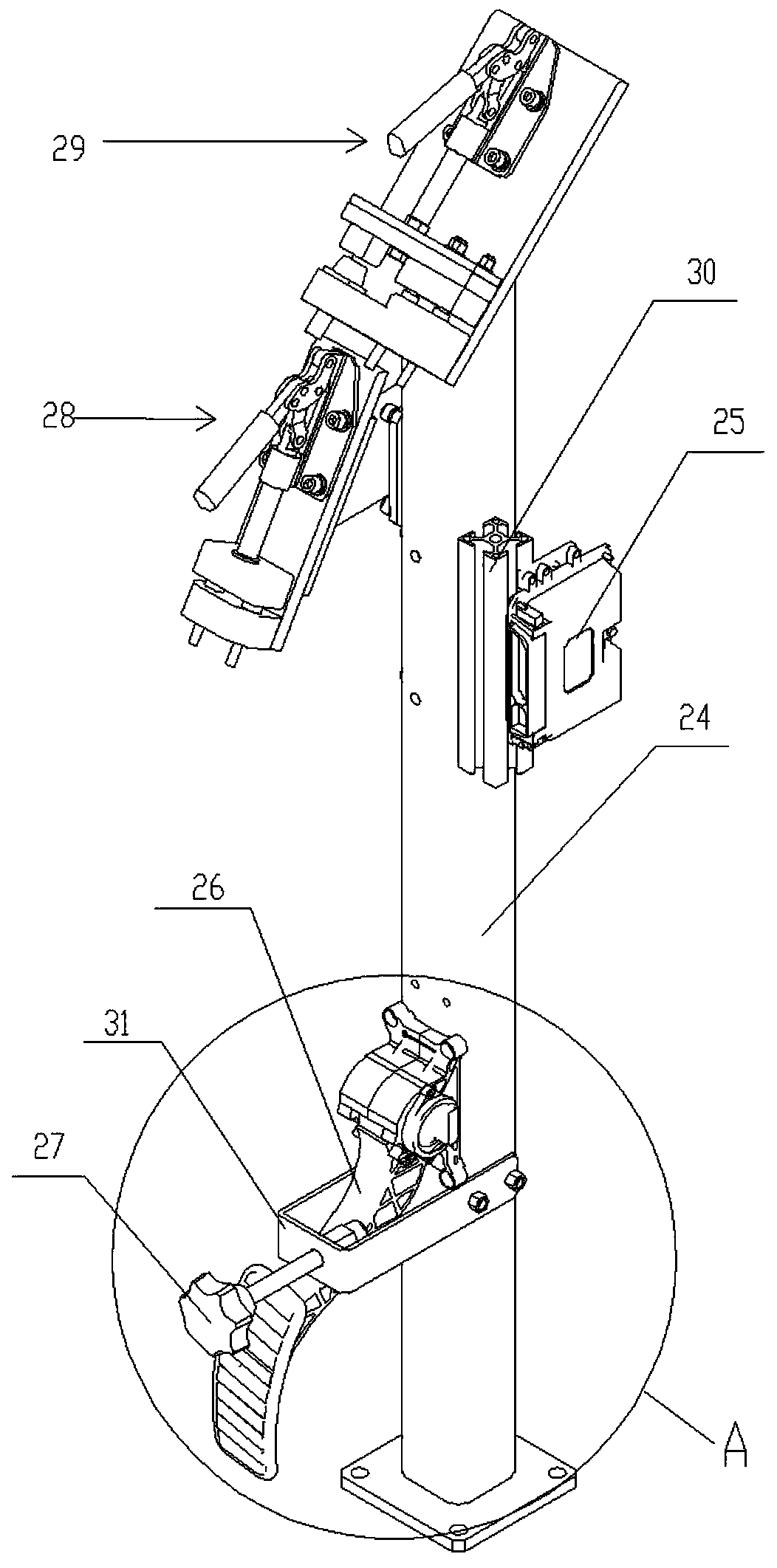

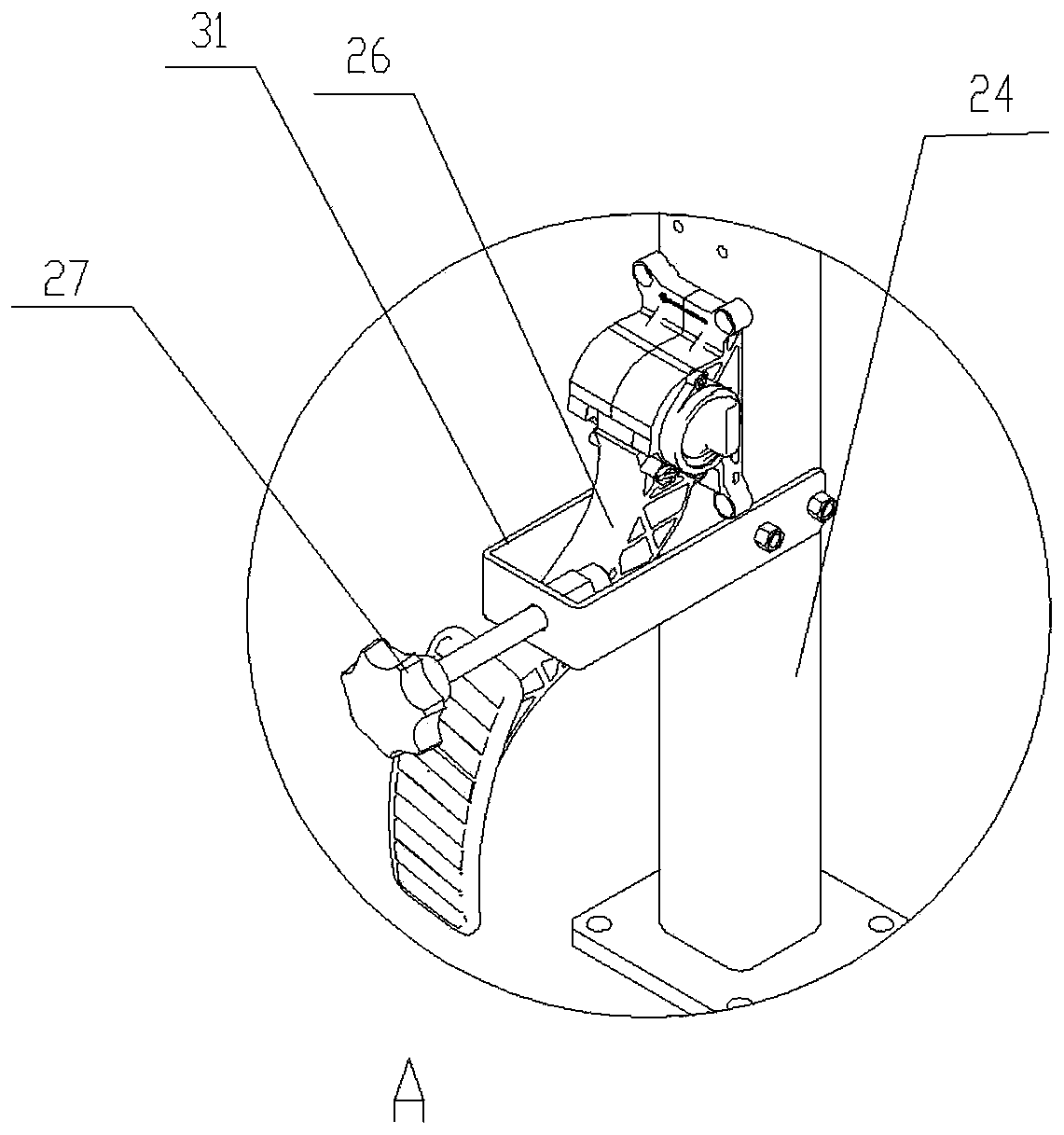

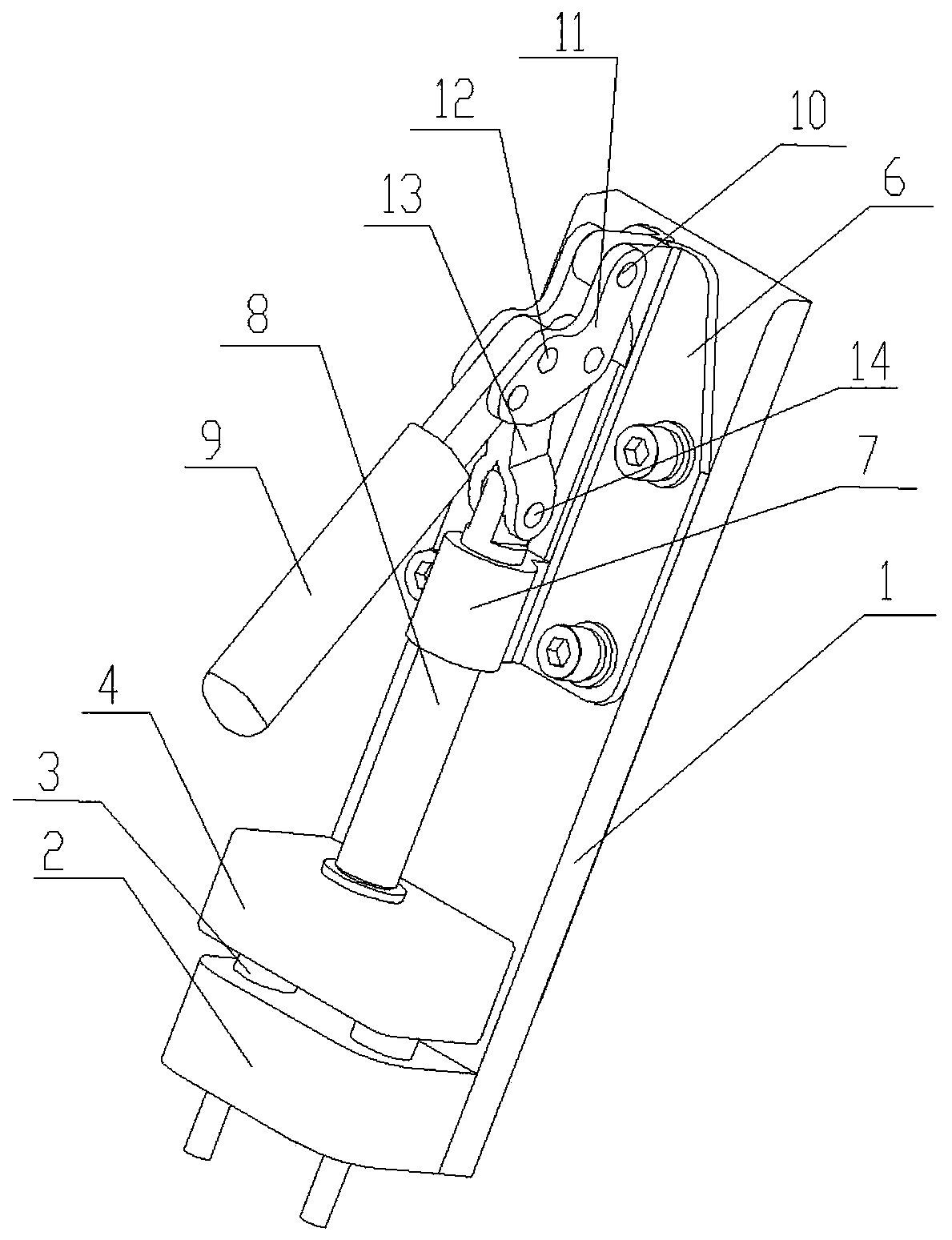

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0024] Such as Figure 1~3 A battery cable quick-change device shown includes a column 24, an engine ECU 25 fixedly arranged on the column 24, an engine gas pedal 26, and two wiring quick-pressing tooling; the wiring quick-pressing tooling includes a base plate 1. The fixed plate 2 fixedly arranged on the bottom plate 1, the connecting terminals 3 arranged on the fixed plate 2 are fixed by bolts, and the pressure plate 4 slidably arranged on the bottom plate 1, and the pressure plate is driven 4. A sliding hand brake, the hand brake includes a base plate 6 fixed on the base plate 1, an insert ring 7 fixed on the seat of the base plate 1, and a pressing force hinged on the base plate 6 through the driving arm assembly. A tightening rod 8 and a handle 9 provided on the driving arm assembly, the other end of the tightening rod 8 passes through the insert ring 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com