Method for adapting the output of a steam-turbine power station, and steam-turbine power station

A technology of power generation equipment and steam turbines, applied in mechanical equipment, steam engine devices, machines/engines, etc., can solve the problems of reducing efficiency and achieve the effect of effective power and simple cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

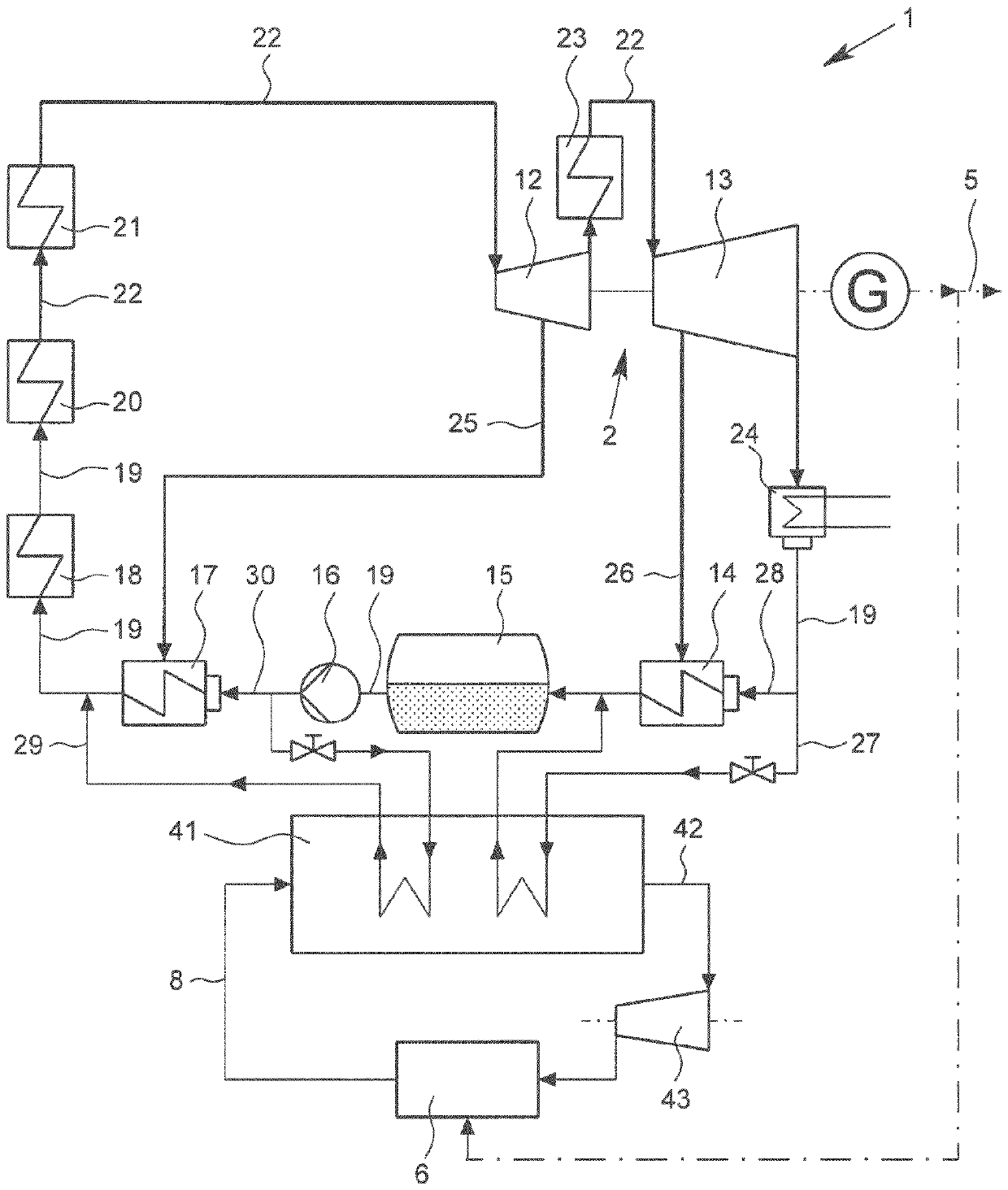

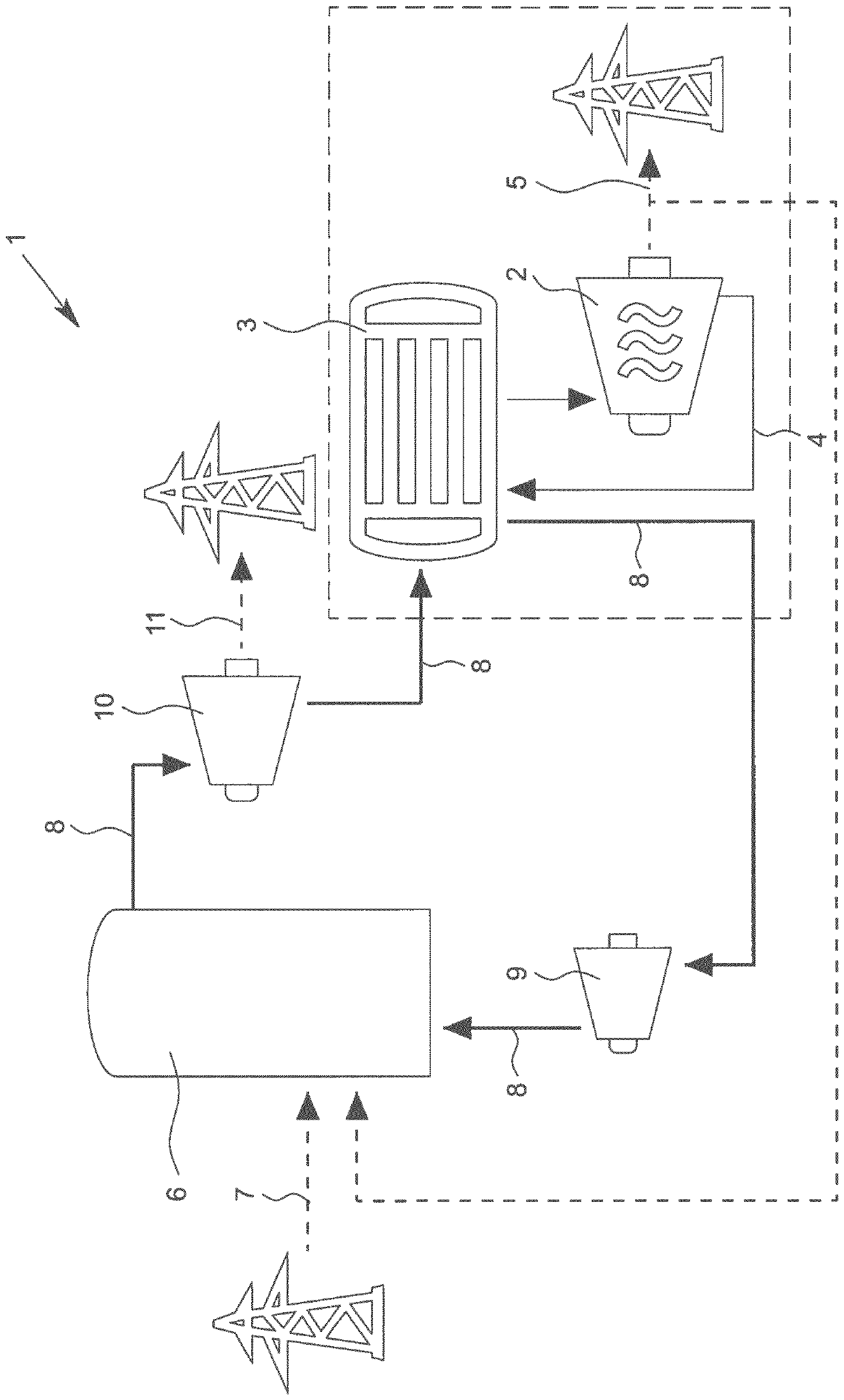

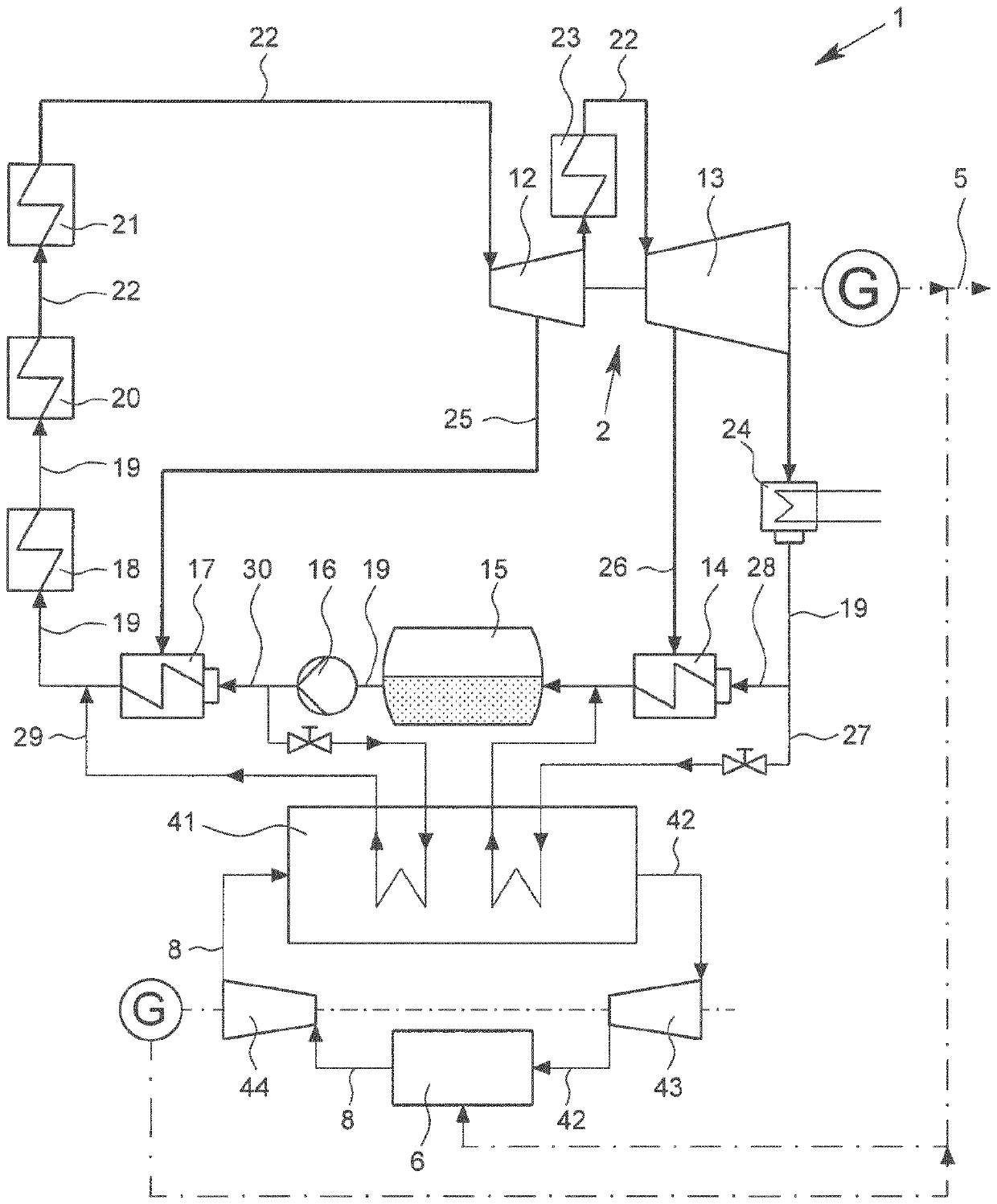

[0042] figure 1 A simplified plant diagram of a steam turbine power plant 1 with a schematically shown steam turbine 2 which can have a high-pressure part, a medium-pressure part and a low-pressure part is shown. Furthermore, the feedwater preheating path 3 of the water-steam-working circuit 4 is schematically shown, in which the feedwater is preheated for subsequent evaporation. The net electric power or active power 5 generated during the power generation is fed into the combined grid. Other equipment components required for electricity generation in steam power processes are in figure 1 not shown in

[0043] In order to quickly and flexibly adapt the real power 5 of the power generation system 1 , and preferably also to provide positive and negative grid regulation power if necessary, at least one electrically loadable thermal store 6 is provided. To load the store 6 , electrical power 7 can be drawn from the power grid 7 and / or a portion of the electrical energy produce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com