Rice paste manufacturing method applicable to vacuum wall breaking machine

A vacuum wall breaker and a technology of a production method, which are applied in the field of food processing, can solve the problems of poor taste, easy oxidation, unfavorable digestion and absorption of materials, etc., and achieve the benefits of digestion and absorption, improvement of taste and flavor, and improvement of conversion efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

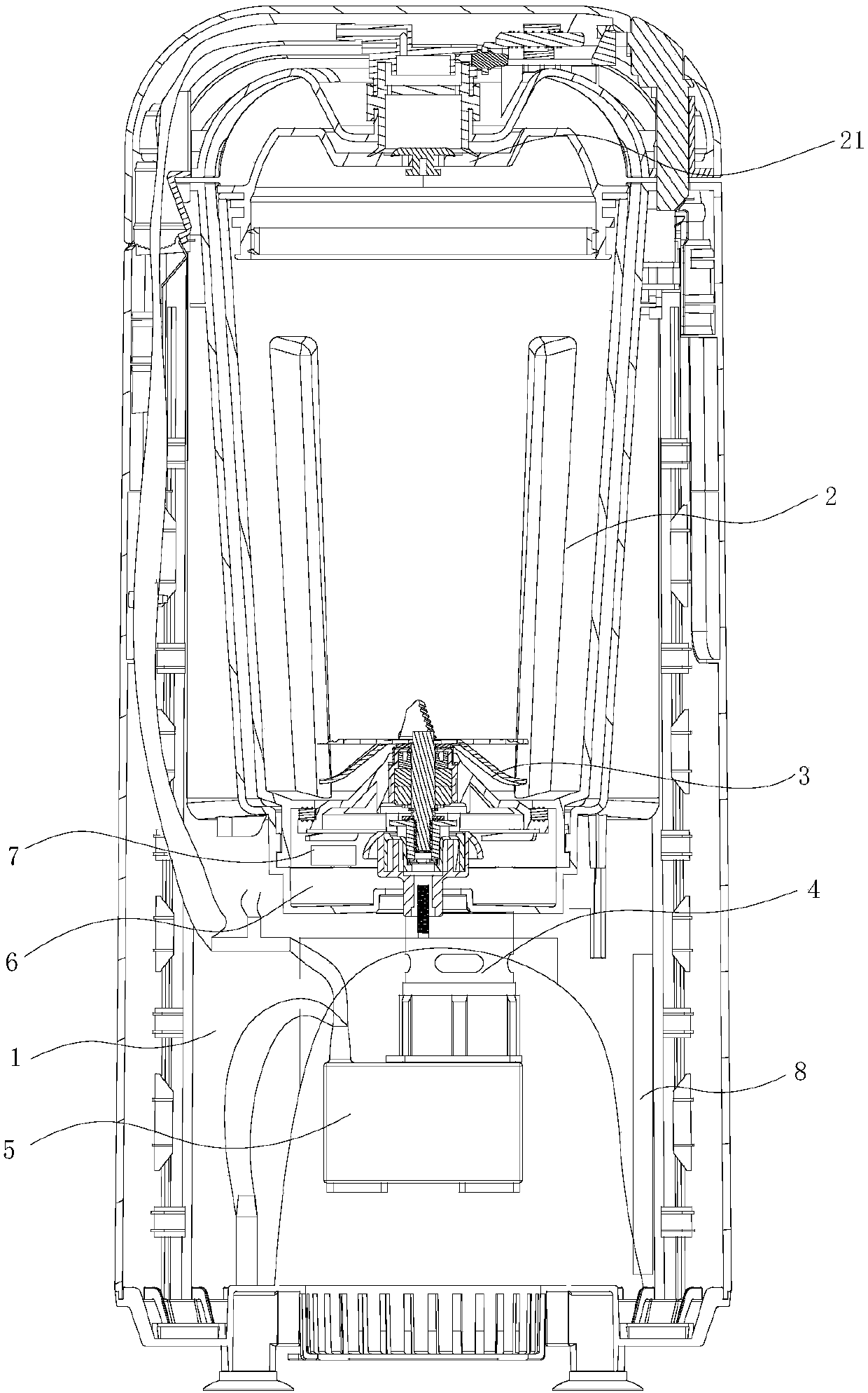

[0031] Embodiment one: if figure 1 As shown, a method for making rice paste suitable for a vacuum wall breaking machine, the vacuum wall breaking machine includes a machine base 1 and a stirring cup 2, the stirring cup 2 is arranged on the machine base 1, and the stirring cup 2 includes Cup cover 21 and a stirring chamber is formed in the stirring cup 2, a pulverizing knife 3 is arranged in the stirring chamber, a motor 4 is arranged in the base 1 and the motor 4 is connected with the pulverizing knife 3 through a shaft coupling, so The motor 4 can drive the pulverizer 3 to rotate circumferentially and complete the pulverization of the material; the bottom of the stirring cup 2 is provided with a heating element 6, and the heating element 6 can heat the material in the stirring chamber; A vacuum pump 5 is provided, and the vacuum pump 5 has an air intake pipeline communicated with the stirring chamber and an air outlet pipeline communicated with the outside world, and the vacu...

Embodiment 2

[0041] The difference between this embodiment and Embodiment 1 is that the circuit board 8 heats the material to the first temperature through the heating element 6, and the first temperature is 45°C-65°C, and the vacuum pump 5 is stirring at the first temperature. The cup 2 is vacuumed, and the preset value of the air pressure is -70KPa~-50KPa, and the material that has been vacuumed in the stirring cup 2 is soaked. The soaking time of the material is T, 2min≤T≤40min, in this implementation In the example, the first temperature is 55°C, the preset value of the air pressure is -70KPa, and the soaking time of the material is T=15min, that is to say, the stirring cup 2 is evacuated to the air pressure at 55°C The value is -70KPa and the material is soaked for 15 minutes. This setting ensures that the vacuum pump 5 can vacuum the stirring cup thoroughly when the first temperature is 55°C, and prevents the gas from separating out of the water after the vacuuming is completed. The ...

Embodiment 3

[0045] The difference between this embodiment and Embodiment 1 is that a soaking stage is provided after the vacuuming stage, and the soaking stage and the crushing stage are carried out synchronously, that is to say, the motor 4 drives the material during the soaking stage. The crushing knife 3 completes the crushing of the material. During the soaking stage, the circuit board 8 controls the heating element 6 to heat the material in the stirring chamber to a second temperature. The second temperature is 85°C-95°C. In this embodiment, the first The second temperature is 90°C; the pulverizer 3 drives the pulverizer 3 to pulverize materials at intervals at the first and second speeds. In this embodiment, the first speed is n2, 2000r / min≤n2≤8000r / min, so The second rotating speed is n3, 8000r / min

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap