Fixing tool

A technology for fixing tools and the first tool, which is applied in the direction of manufacturing tools, hand-held tools, workpiece clamping devices, etc., can solve the problems that the preset torque of the screw connection position cannot be guaranteed, time-consuming and labor-intensive, etc., so as to save labor intensity and improve reliability. The effect of ensuring reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation, structure, characteristics and features of a fixing tool proposed according to the present invention will be described below in conjunction with the accompanying drawings and preferred embodiments. Efficacy, detailed as follows.

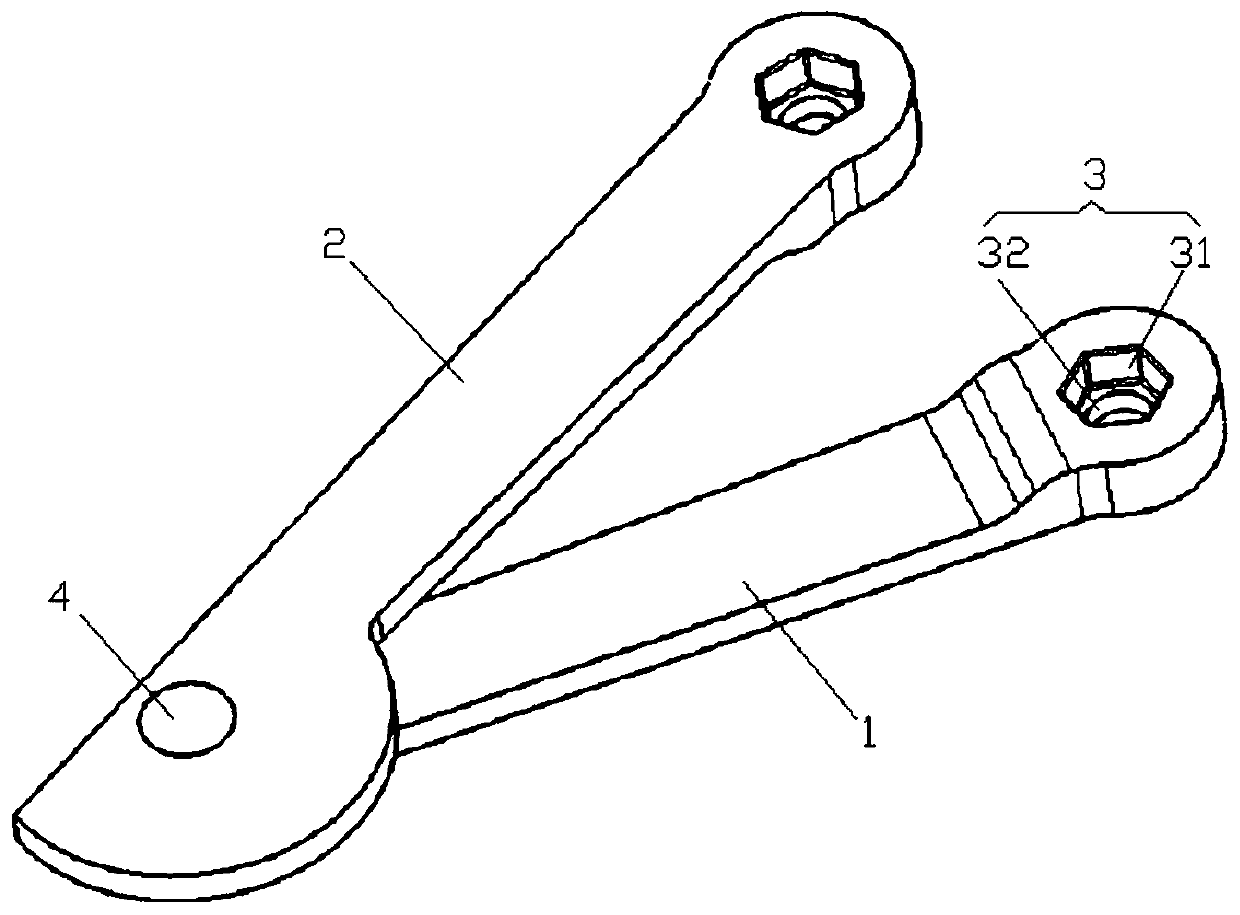

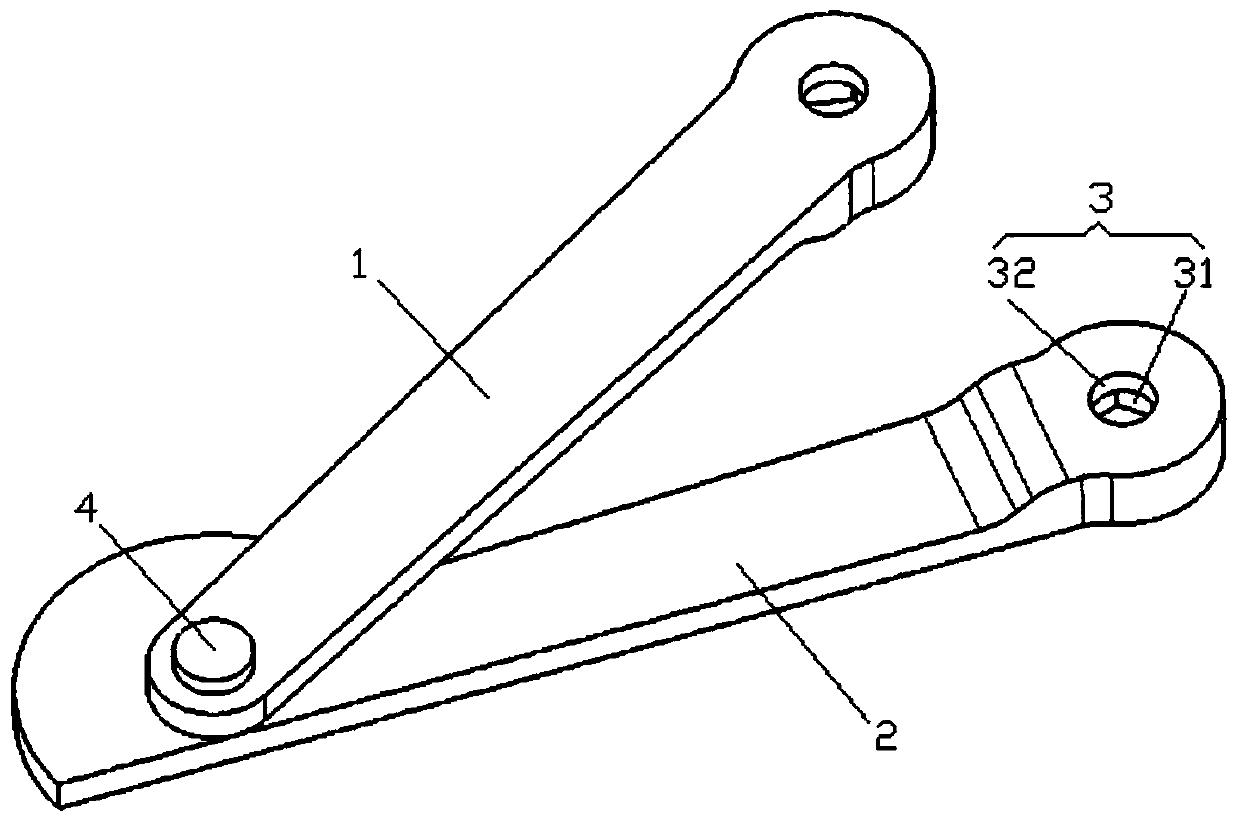

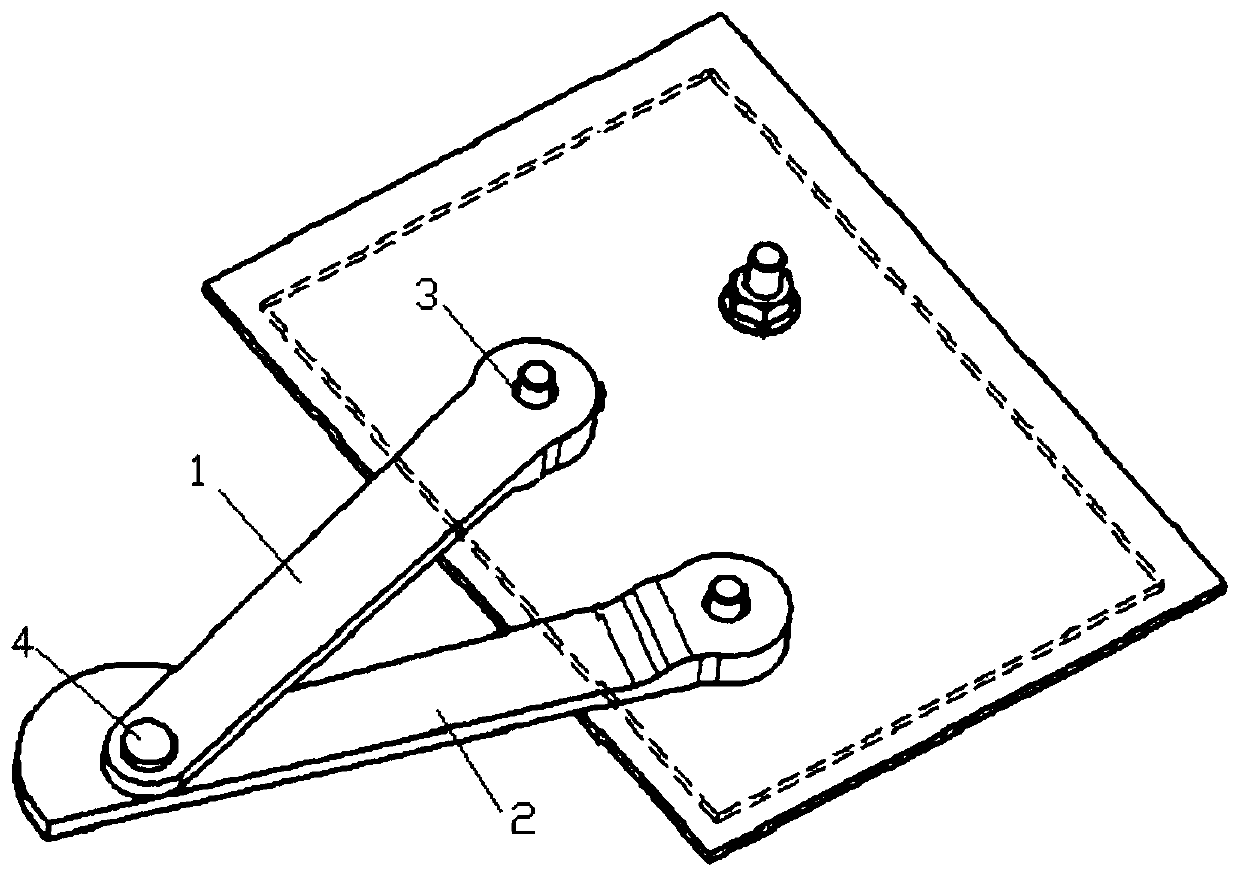

[0027] Such as Figure 1-Figure 8 As shown, the first embodiment of the present invention proposes a fixing tool, which includes: a first tool arm 1; a second tool arm 2, a first end of the first tool arm 1 and a first end of the second tool arm 2; The ends are movably connected, and the second end of the first tool arm 1 and the second end of the second tool arm 2 are respectively pierced with fixing holes 3 for accommodating and fixing bolts or nuts; wherein, the first tool arm 1 and the second tool arm 2 A first angle is formed between the tool arms 2 , so that the second end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com