Underground diaphragm wall bottom reinforcing structure and construction method thereof

A technology of underground diaphragm wall and reinforcement structure, which is applied in basic structure engineering, sheet pile wall, building and other directions, can solve the problems of high cost, large supporting cost of water-stop curtain, settlement and deformation of surrounding buildings or foundation subsidence, etc. Achieve the effect of low cost, ensure the safety of foundation pit support, and restrain the problem of uneven settlement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

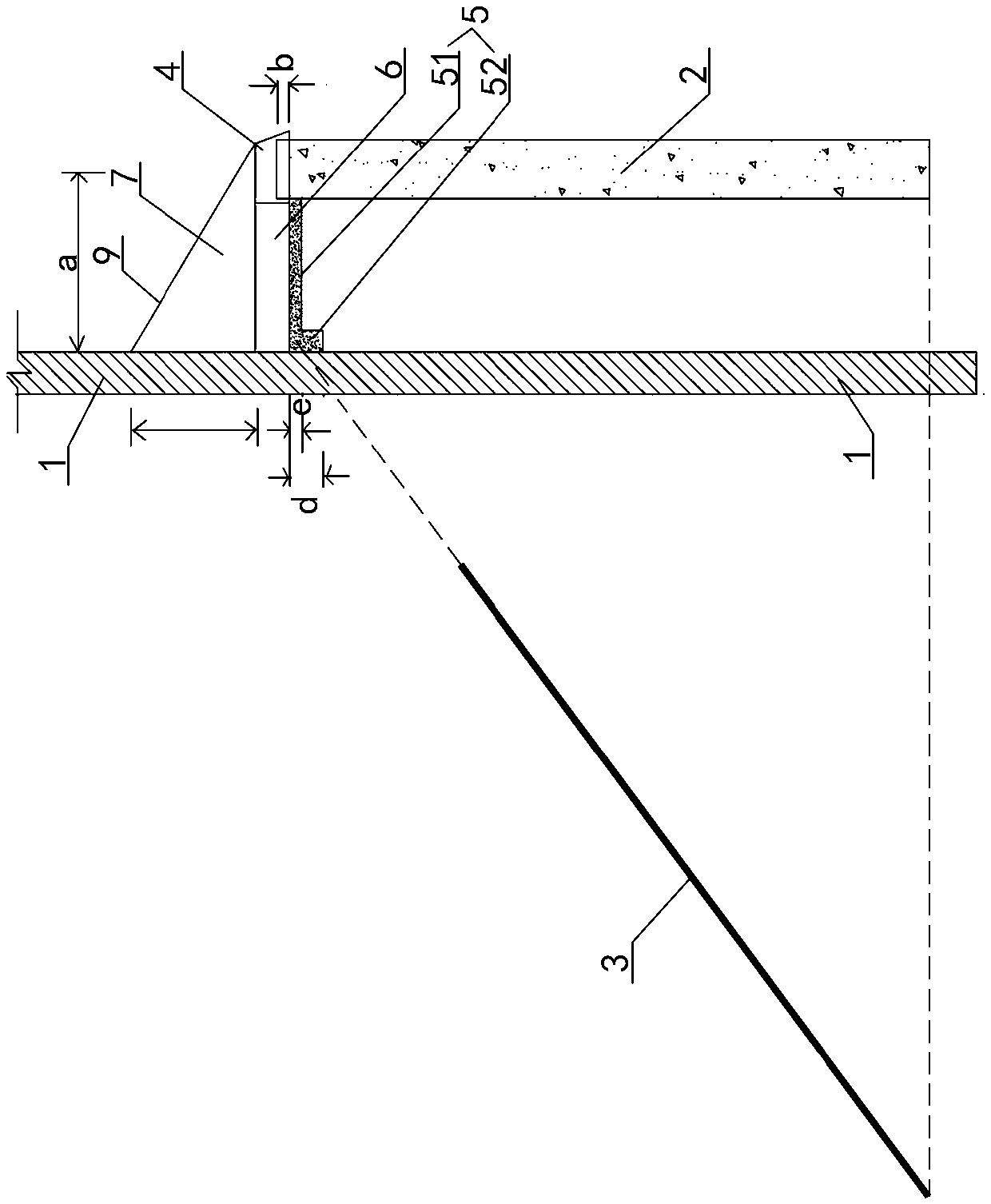

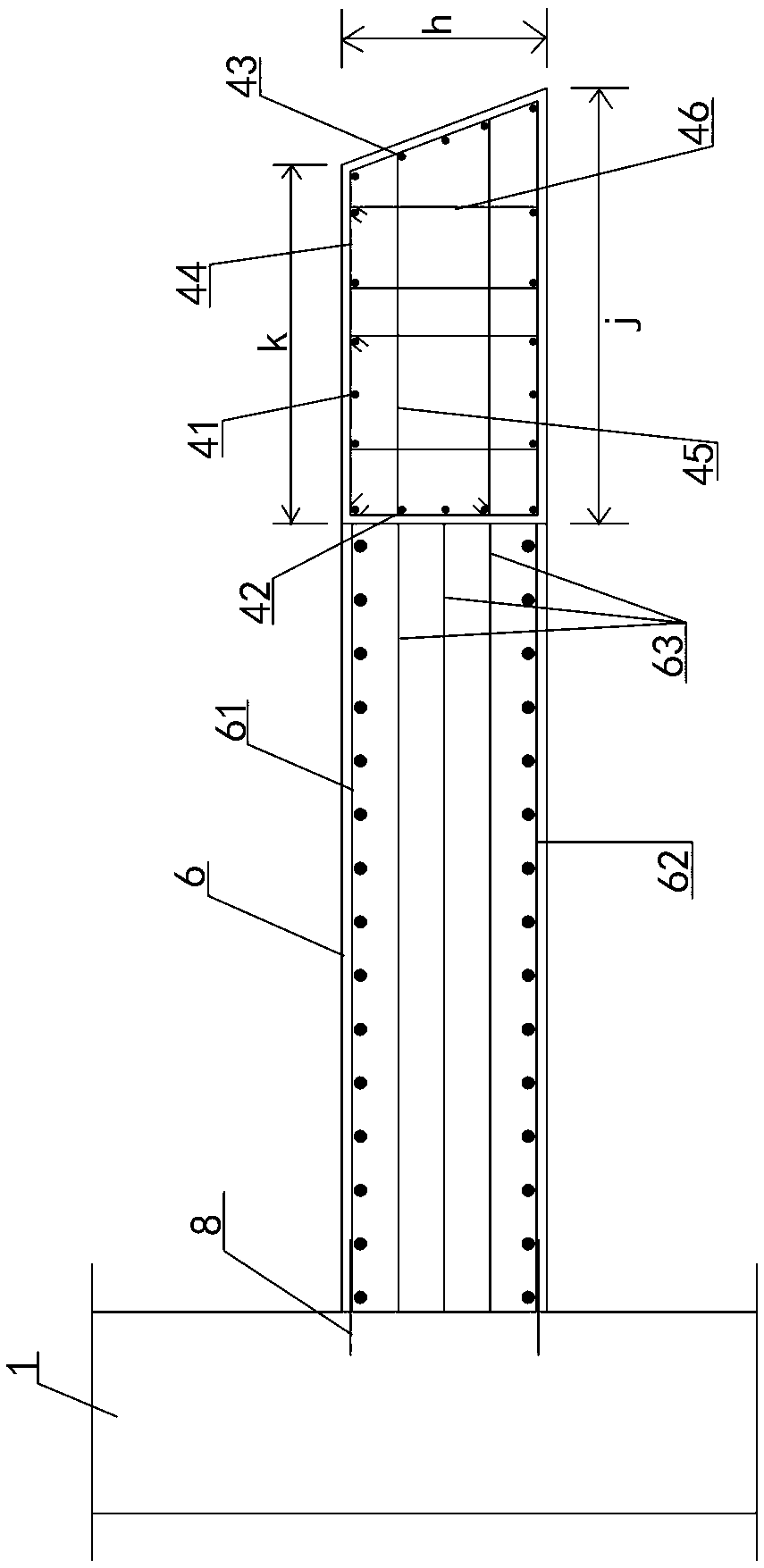

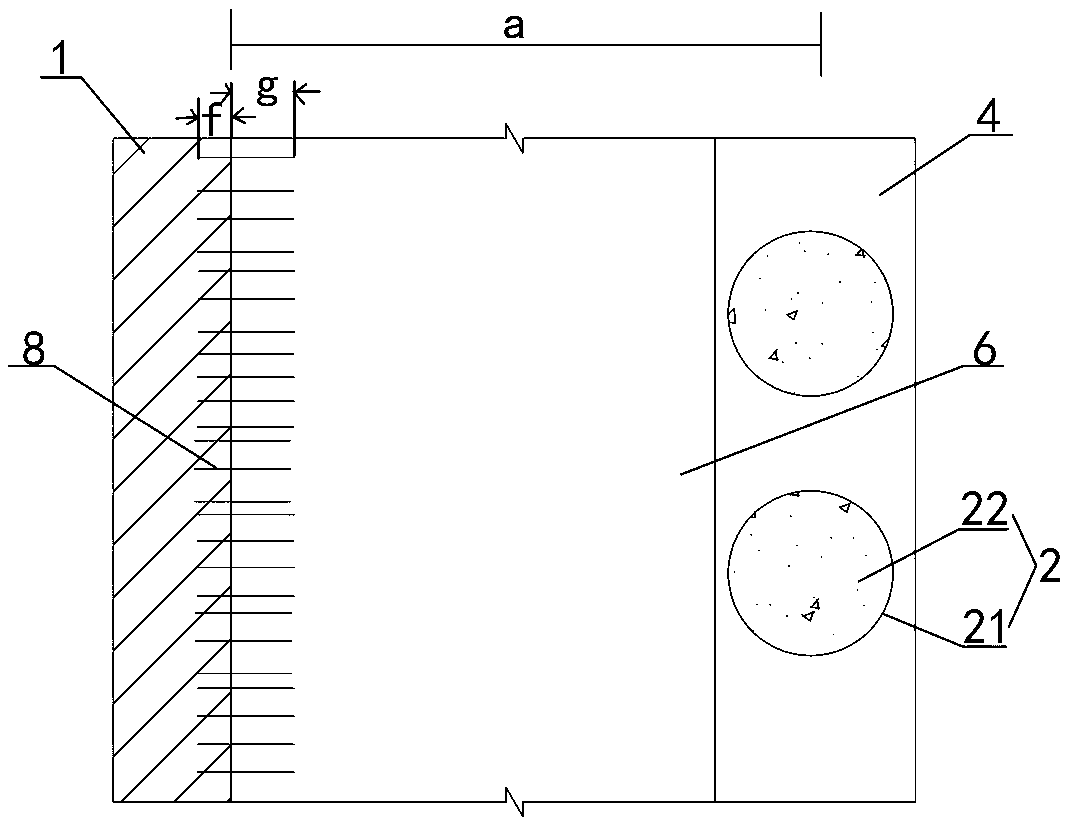

[0052] Examples see Figure 1-4 As shown, a reinforcement structure for the bottom of an underground diaphragm wall includes an underground diaphragm wall 1, and also includes a row of bored piles 2 driven into a row at a distance between the bottom inner side of the underground diaphragm wall and the underground diaphragm wall. The specific reinforcement length It is determined according to the precipitation and the surrounding environment, so as to ensure that the connecting wall covers the part where the anchor cable cannot be laid. The distance between the underground diaphragm wall 1 and the bored pile 2 is a=3m-5m. The lower surface of the bored cast-in-place pile is flush with the bottom end of the bottom row of the underground diaphragm wall where the anchor cables 3 cannot be laid, and the top of the bored cast-in-place pile is connected as a whole by a crown beam 4 . The bored cast-in-place pile 2 is a steel pipe concrete pile, and the thickness b of the top of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com