A track-type automatic detection device for vial lamp inspection machine

An automatic detection device, vial lamp technology, applied in the direction of optical testing flaws/defects, etc., can solve the problems of complex mechanical structure, high cost, and high camera requirements, and achieve the effect of improving detection efficiency, ensuring accuracy and effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

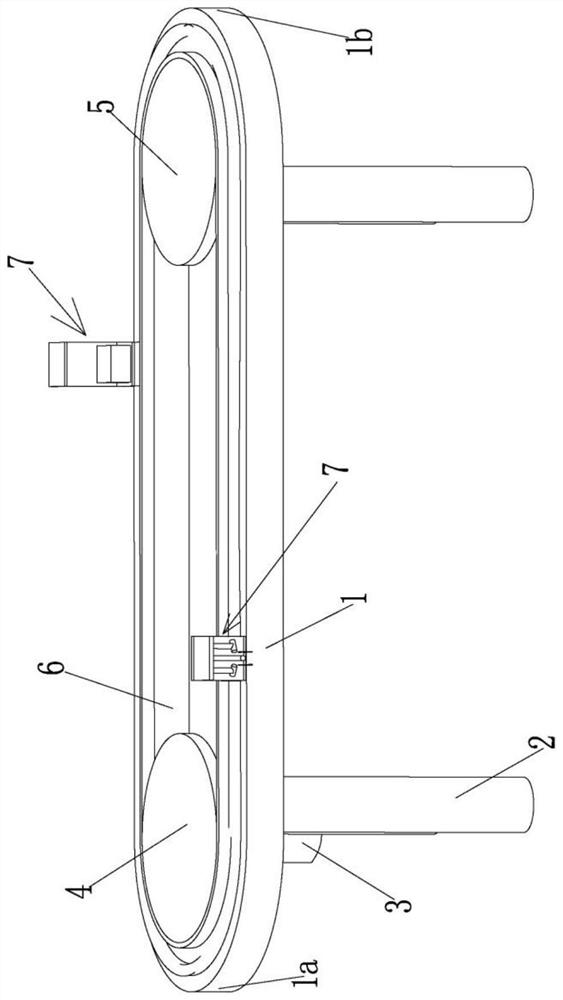

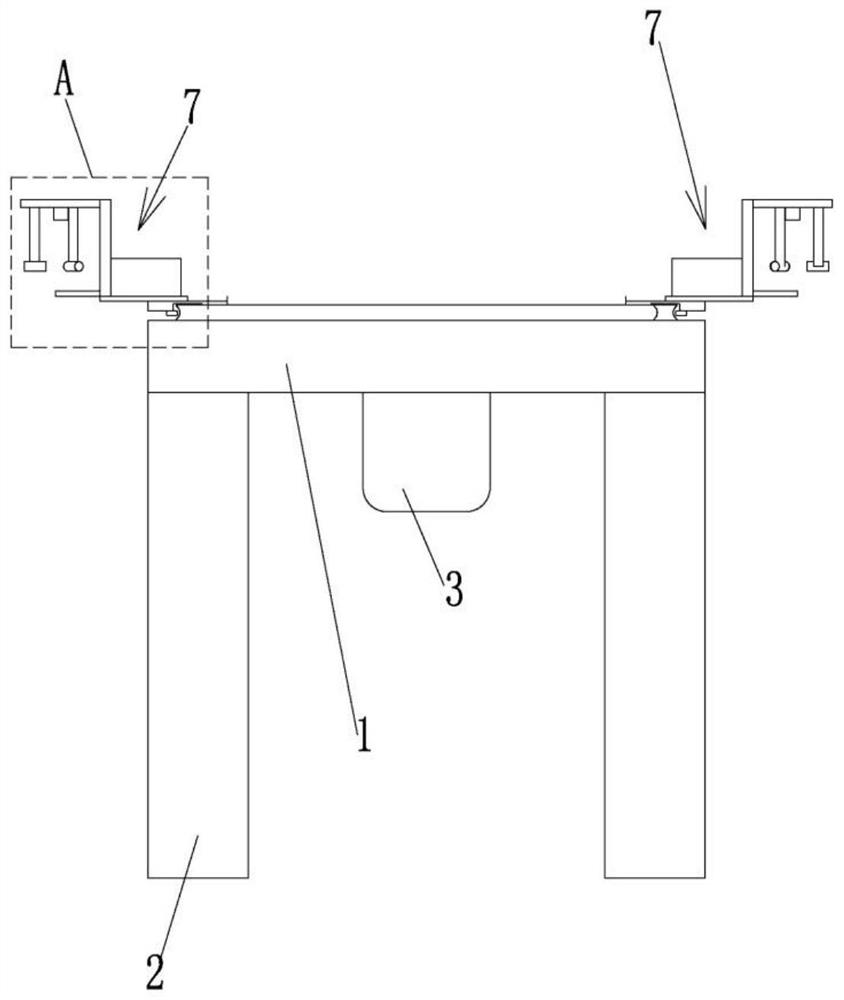

[0020] to combine Figure 1-5 As shown, a track-type automatic detection device for a vial lamp inspection machine includes the following parts:

[0021] The electric control component 8 can be a PLC controller or other electric control unit;

[0022] track support 2;

[0023] The guide rail seat 1 placed on the track support 2;

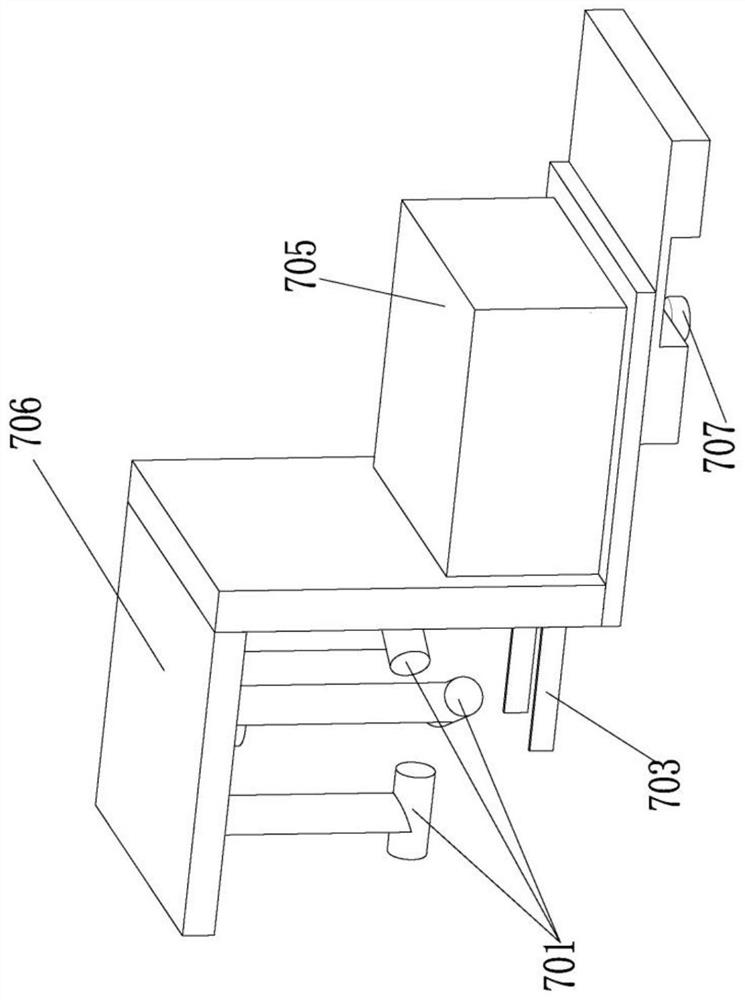

[0024] Two mobile detection units 7 that cooperate with the guide rail seat 1, and the two mobile detection units 7 are arranged at intervals;

[0025] A drive system that drives the two mobile detection units 7 to reciprocate along the length direction of the guide rail base 1 at the same time.

[0026] Wherein, the mobile detection unit 7 includes a clamping mechanism for clamping the vial, and the mobile detection unit 7 is connected with the electric control component 8 .

[0027] The above-mentioned drive sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com