Large pipe cutting machine

A pipe cutting machine, a large-scale technology, applied in metal processing and other directions, can solve the problems of large-scale plastic pipes that are prone to deformation, and achieve the effect of simplifying the cutting process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following is further described in detail through specific implementation methods:

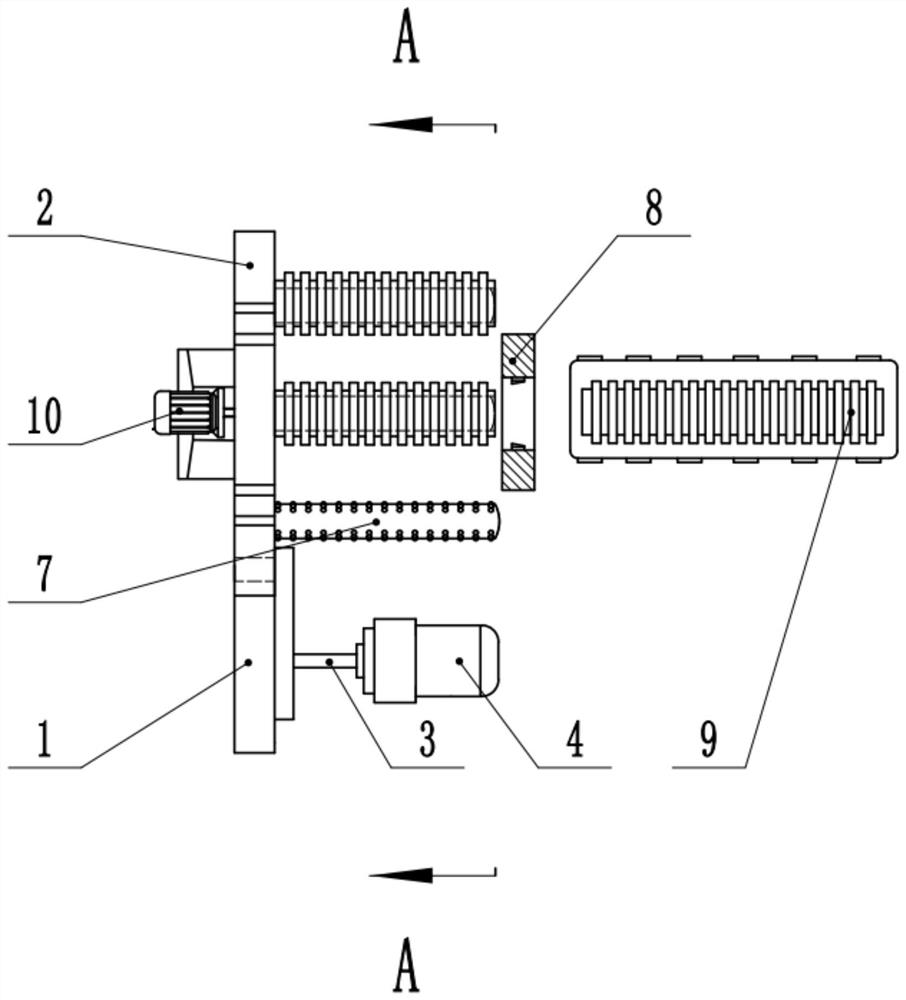

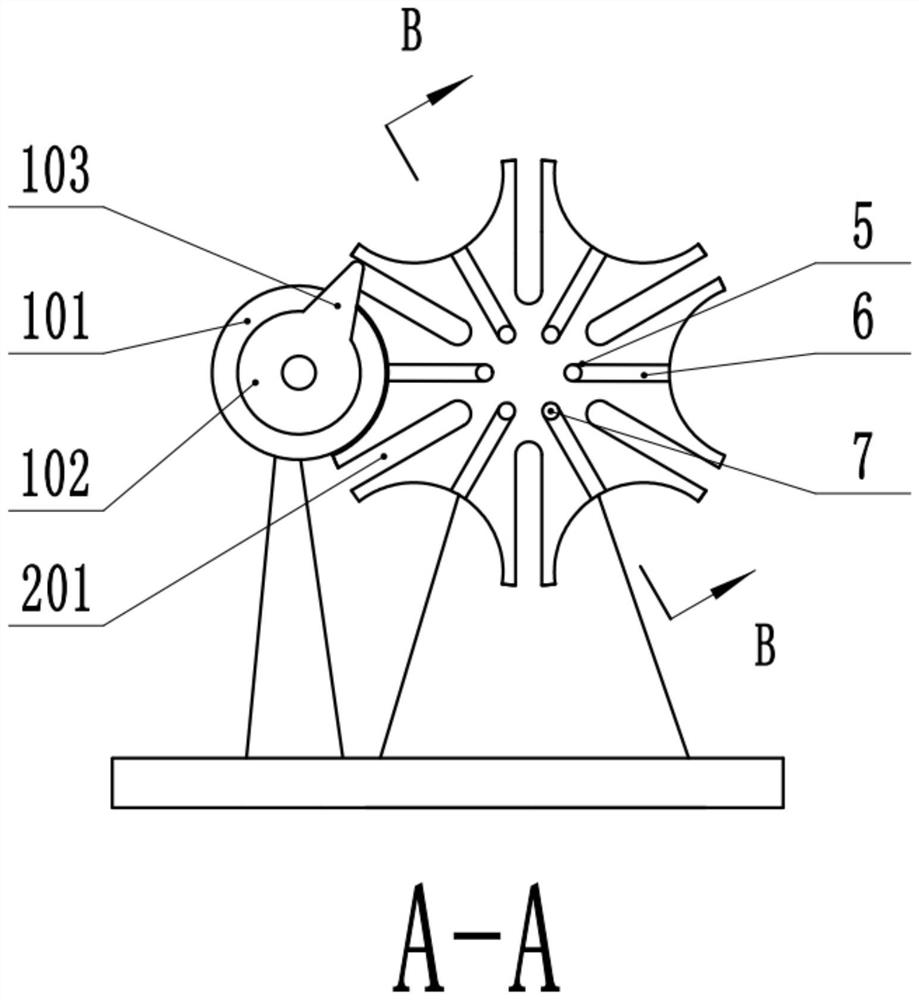

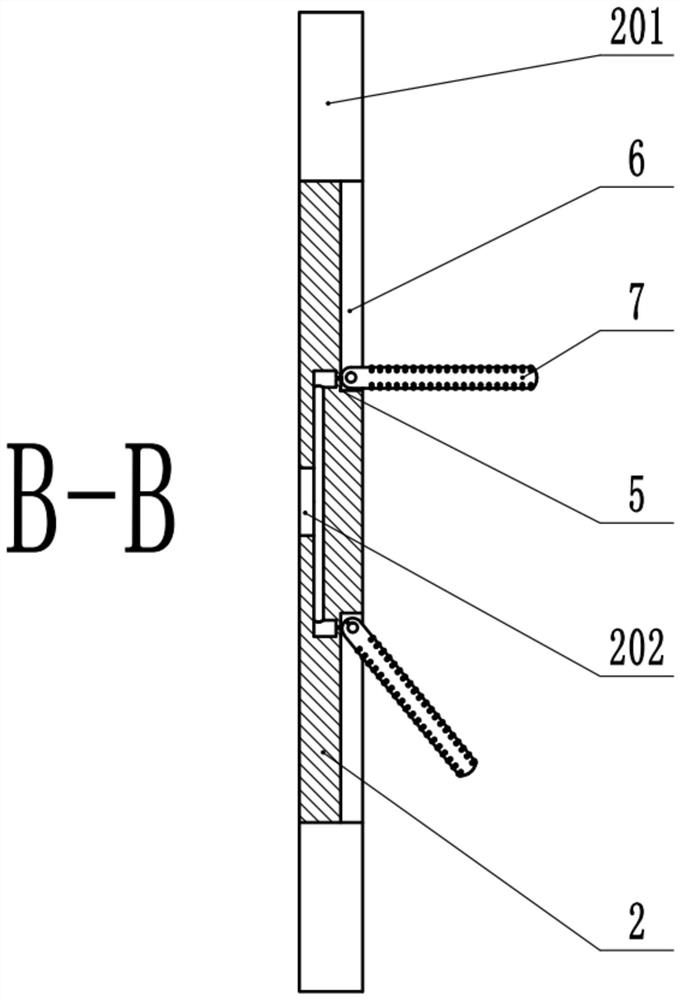

[0023] The reference signs in the accompanying drawings include: driving dial 1, large disc 101, small disc 102, rotating arm 103, sheave 2, bar-shaped slot hole 201, inflation hole 202, drive rod 3, drive motor 4 , right-angle port 5, strip slideway 6, support column 7, limit pin 701, cavity 702, ball 703, injection hole 704, cutting device 8, annular shell 801, cutting knife 802, conveyor belt 9, air pump 10.

[0024] The embodiment is basically as attached figure 1 with attached figure 2 Shown: a large pipe cutting machine, including a frame, the frame is provided with a transfer device and a cutting device 8. The transfer device includes a driving dial 1 and a sheave 2 . The driving dial 1 is composed of a large disc 101 and a small disc 102 respectively. The small disc 102 is disposed on the axial end surface of the large disc 101 , the center of the large disc 101 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com