Regulating valve detection device

A detection device and control valve technology, applied in valve devices, engine components, mechanical equipment, etc., can solve the problem of failure analysis of control valves that cannot detect data transmission, maintenance of missing control valves, inability to achieve online, timely and effective control and analysis and adjustment Valve operation information and other issues, to achieve the effect of predictive maintenance, extensive application, efficient maintenance programs and on-site maintenance services

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

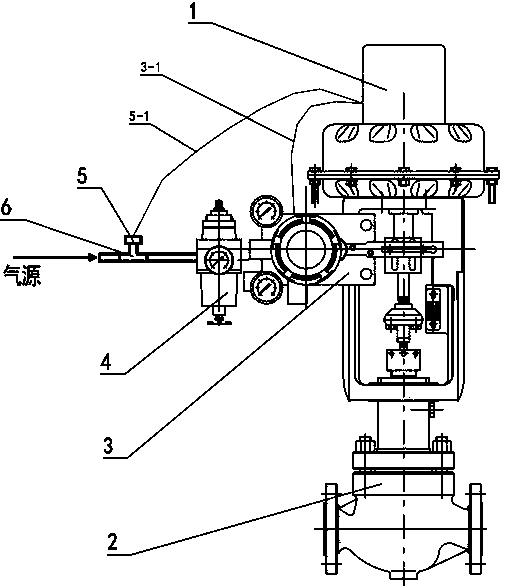

[0025] Such as figure 1 As shown, a regulating valve detection device, the regulating valve 2 is connected with an actuator, and a positioner 3 is installed on the actuator; One end of the tee 6 is connected to the air source pressure sensor 5 . An input signal collector for monitoring the input signal of the positioner 3 is installed in the positioner 3 .

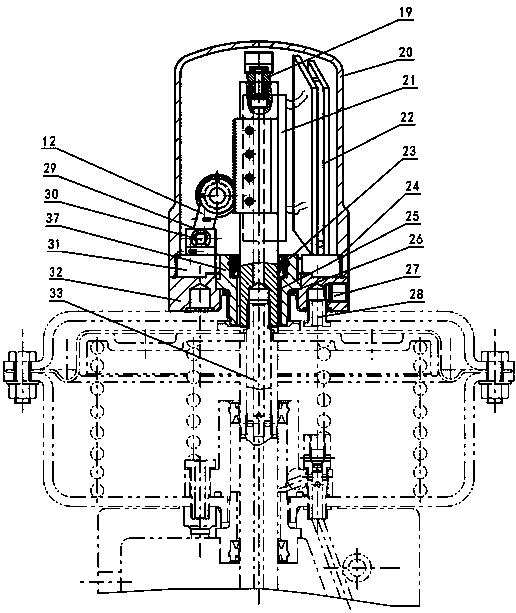

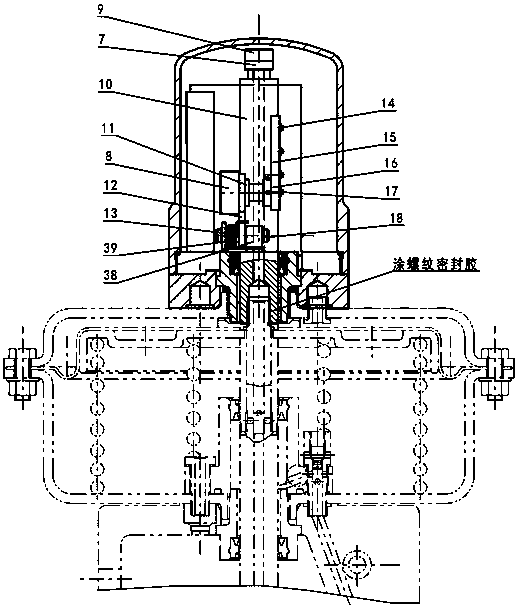

[0026] recombine Figure 2 to Figure 5 as shown,

[0027] The connecting rod 10 is connected with the control rod of the actuator through the push rod 33 . The push rod 33 is a stepped shaft, and the two ends of the push rod 33 are threaded. One end of the push rod 33 is threaded to the control rod of the actuator, and the other end is threaded to the connecting rod 10. Has thread sealant. The push rod 33 , the control rod of the actuator, and the connecting rod 10 are through-holes, and the through-hole at the outer end of the connecting rod 10 is connected to the membrane chamber pressure sensor 7 and the dynamic th...

Embodiment 2

[0040] On the basis of above-mentioned embodiment one;

[0041] combine Figure 6 As shown, the circuit board system includes a fault diagnosis device and a detection data analysis software. The microprocessor of the fault diagnosis device is STM32F407, and the peripherals mainly include ADC, PWM, WIFI, USB, RS232 and touch screen. The touch screen is the above-mentioned embodiment 1. LCD screen 36.

[0042] When fault diagnosis is to be performed on the valve, the operator sends a diagnosis instruction to the regulating valve diagnosis system through the touch screen. After receiving the instruction, the microprocessor generates PWM to output 4-20mA current. After the positioner receives the current signal, it controls the opening and closing of the valve. At this time, the membrane chamber pressure sensor 7, the dynamic thrust strain sensor 9, the displacement sensor 8, and the air source pressure sensor 5 collect valve data, and transmit the data to the STM32F407 micropr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com