Dead weight type triaxial apparatus water injection and drainage device

A technology of triaxial meter and water injection, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of cumbersome and inconvenient use of triaxial meter, and achieve the effect of low cost and suitable for production and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

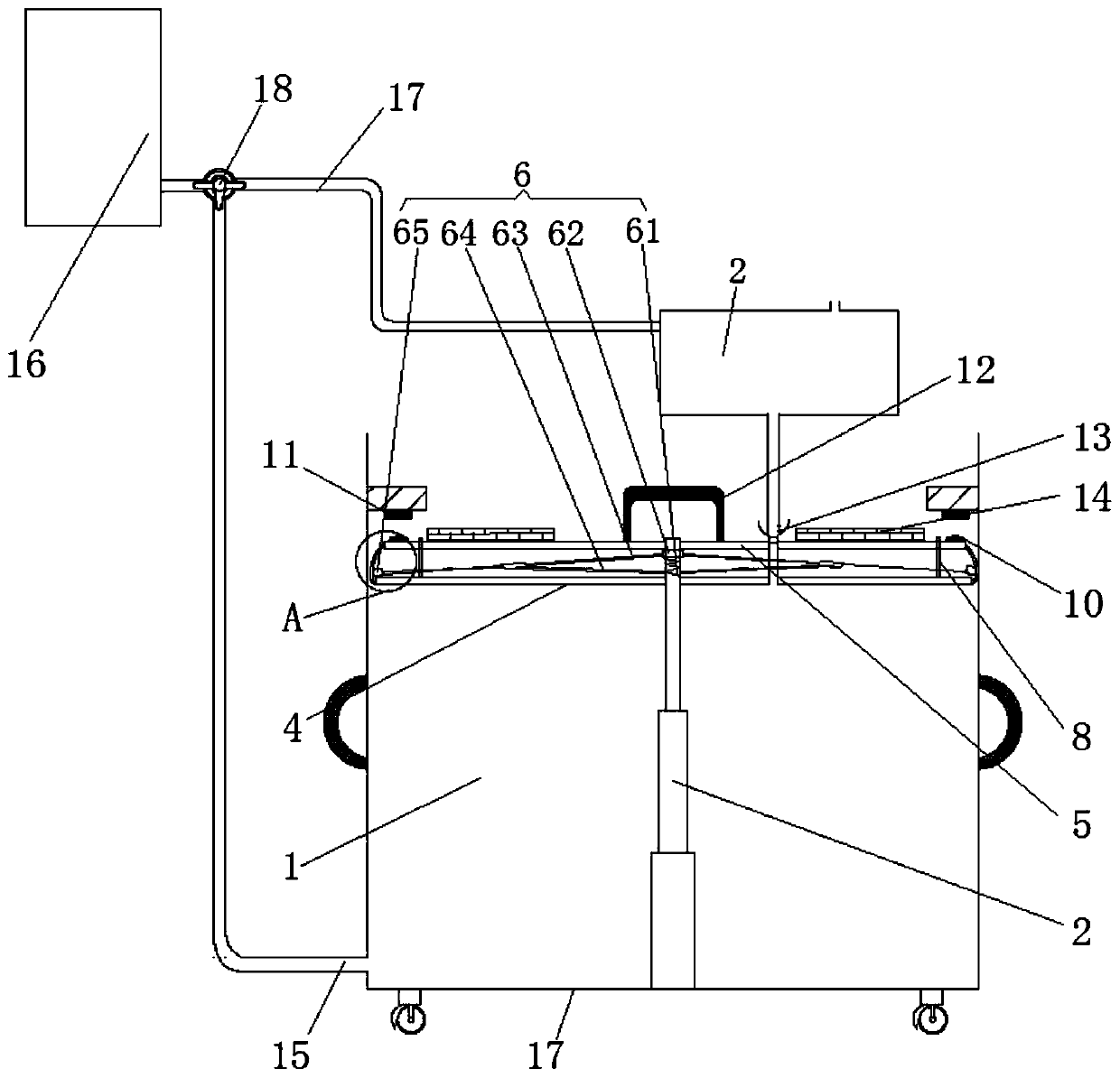

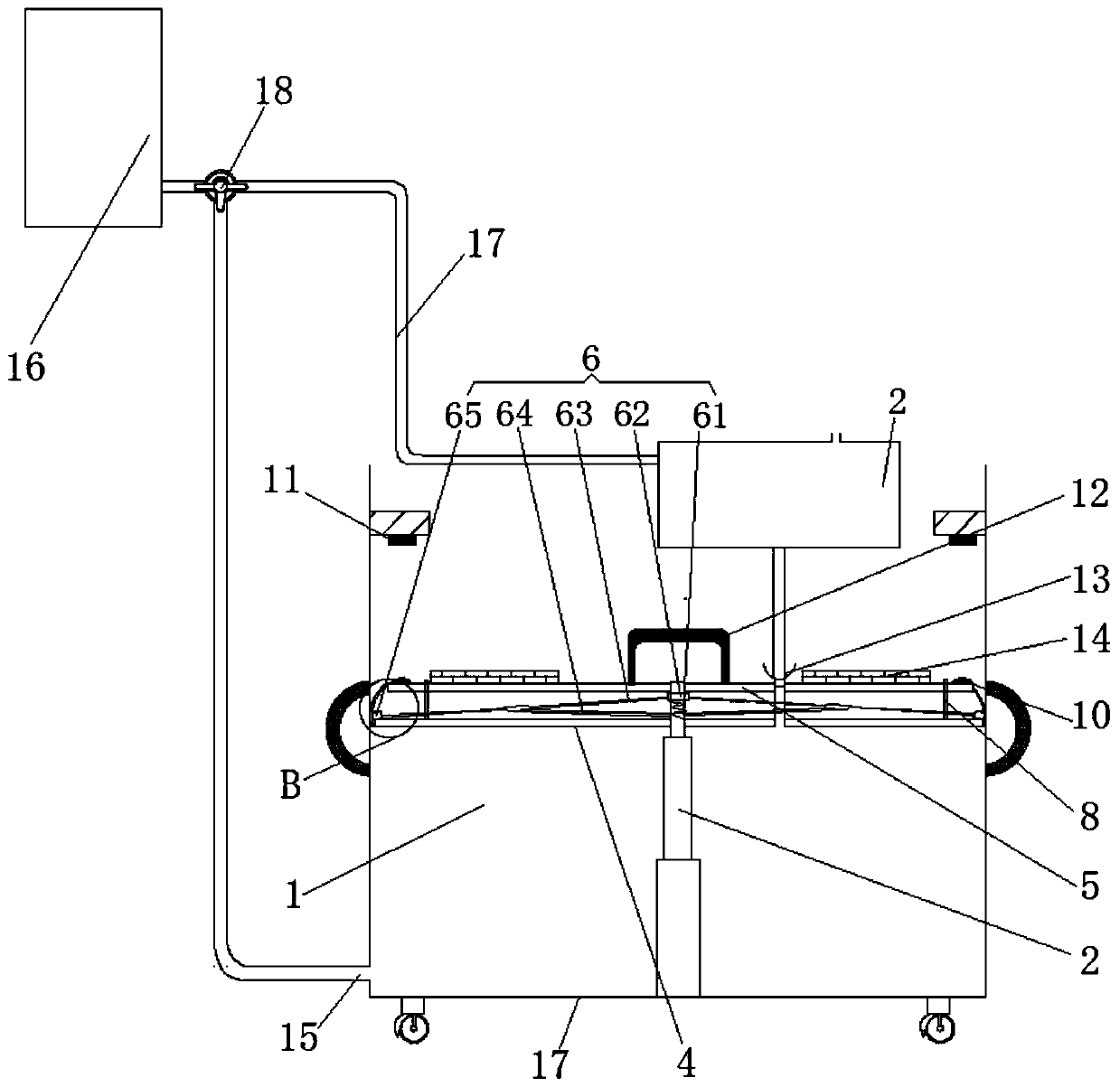

[0026] The present invention will be further elaborated below by means of the accompanying drawings and examples.

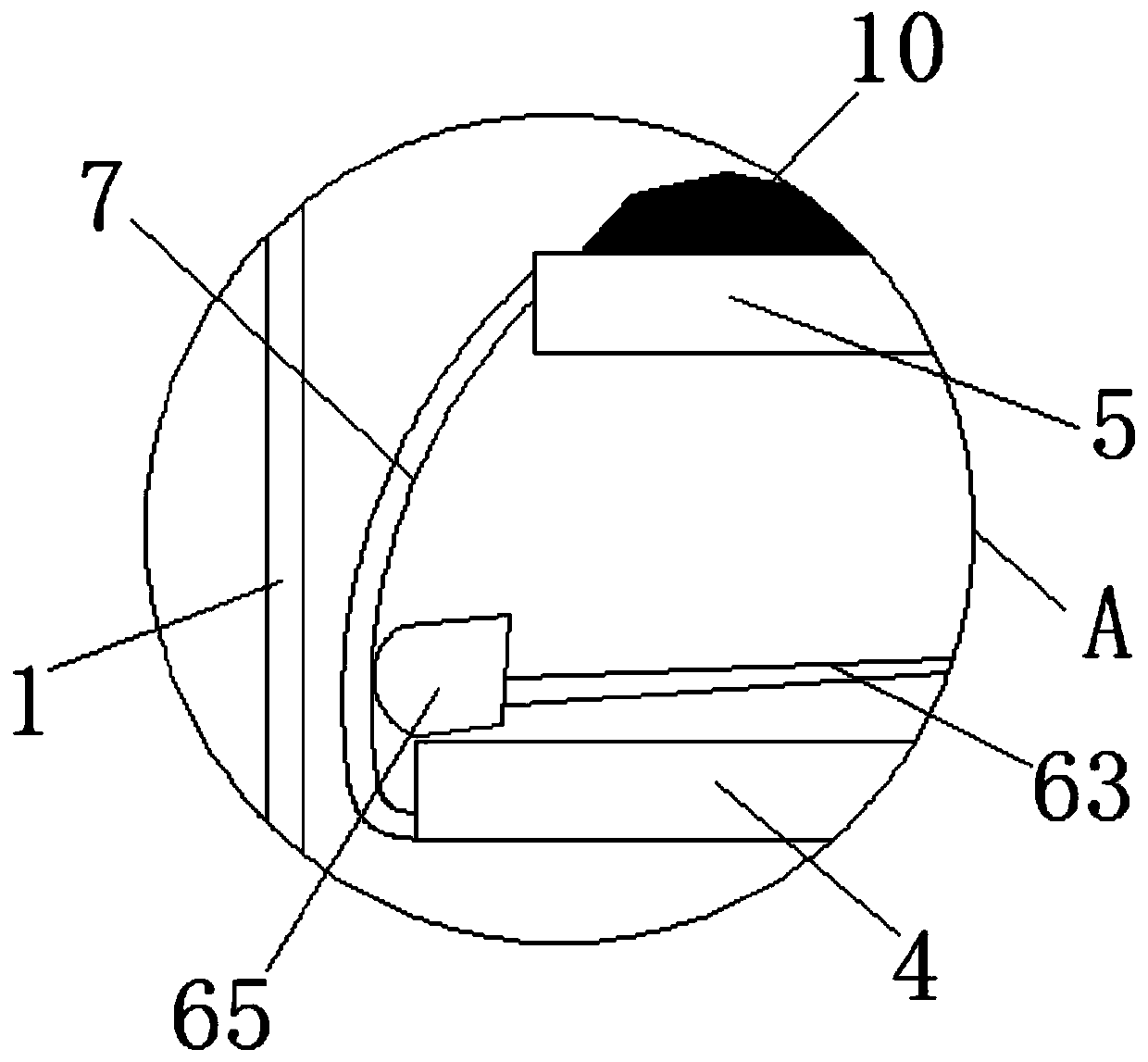

[0027] Such as Figure 1-9 Shown: a self-weight type triaxial instrument drainage device, including a container 1, a telescopic rod 2, a water tank 3, a pressure plate 4, a pressure plate 2 5, and a sealing member 6. The telescopic rod 2 is installed in the container 1 . The container 1 communicates with the water tank 3 through the water inlet pipe 13, and the bottom of the container 1 is provided with a water injection pipe 15, and the water injection pipe 15 communicates with the pressure chamber 16 in the triaxial instrument. The first pressing plate 4 is sleeved on the telescopic rod 2, and the second pressing plate 5 is movably sleeved on the telescopic rod 2, and is located above the first pressing plate 4.

[0028] The sealing member 6 is arranged between the first pressing plate 4 and the second pressing plate 5 . The outer edges of the first pressing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com