Patents

Literature

94results about How to "Suitable for production use" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

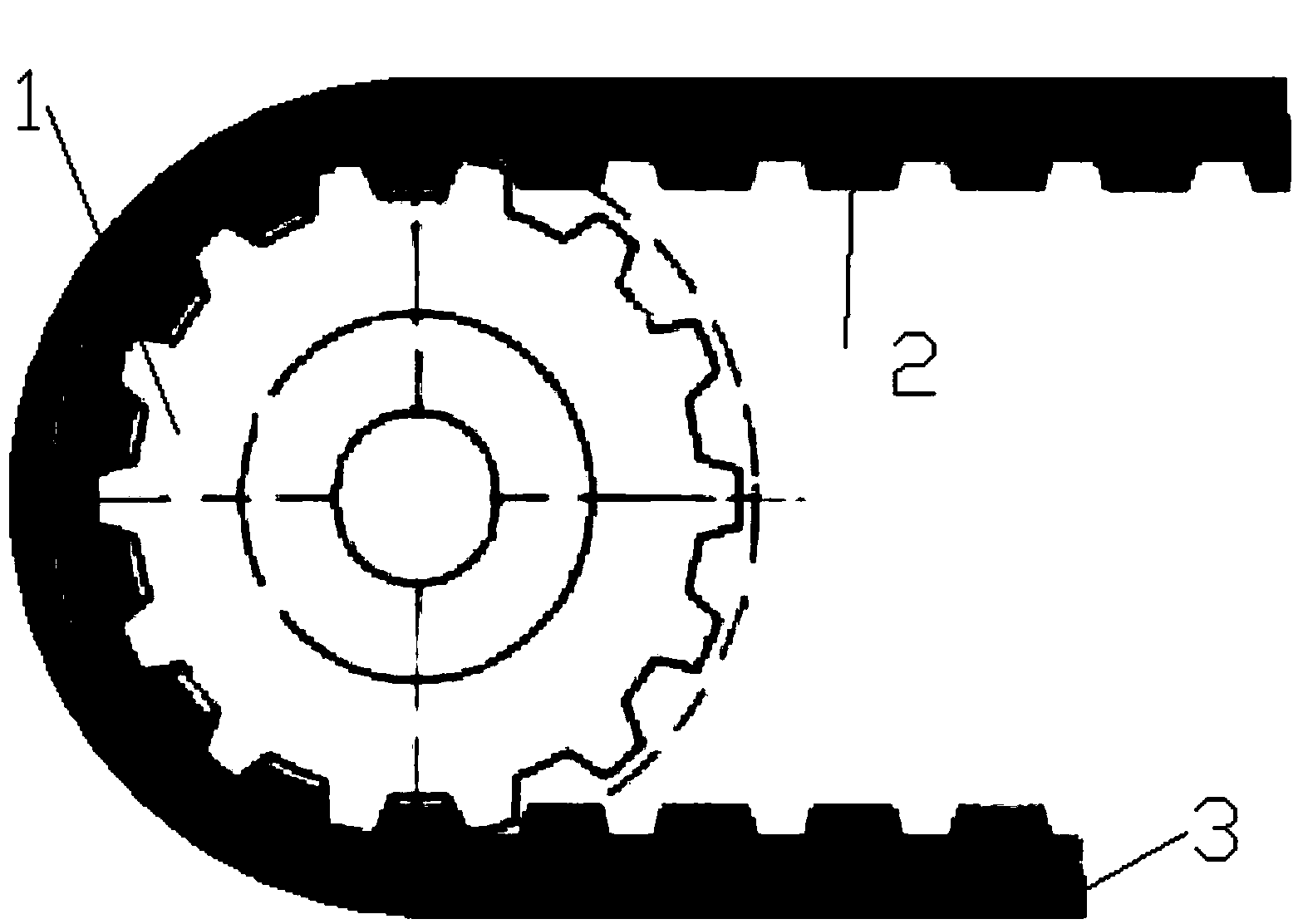

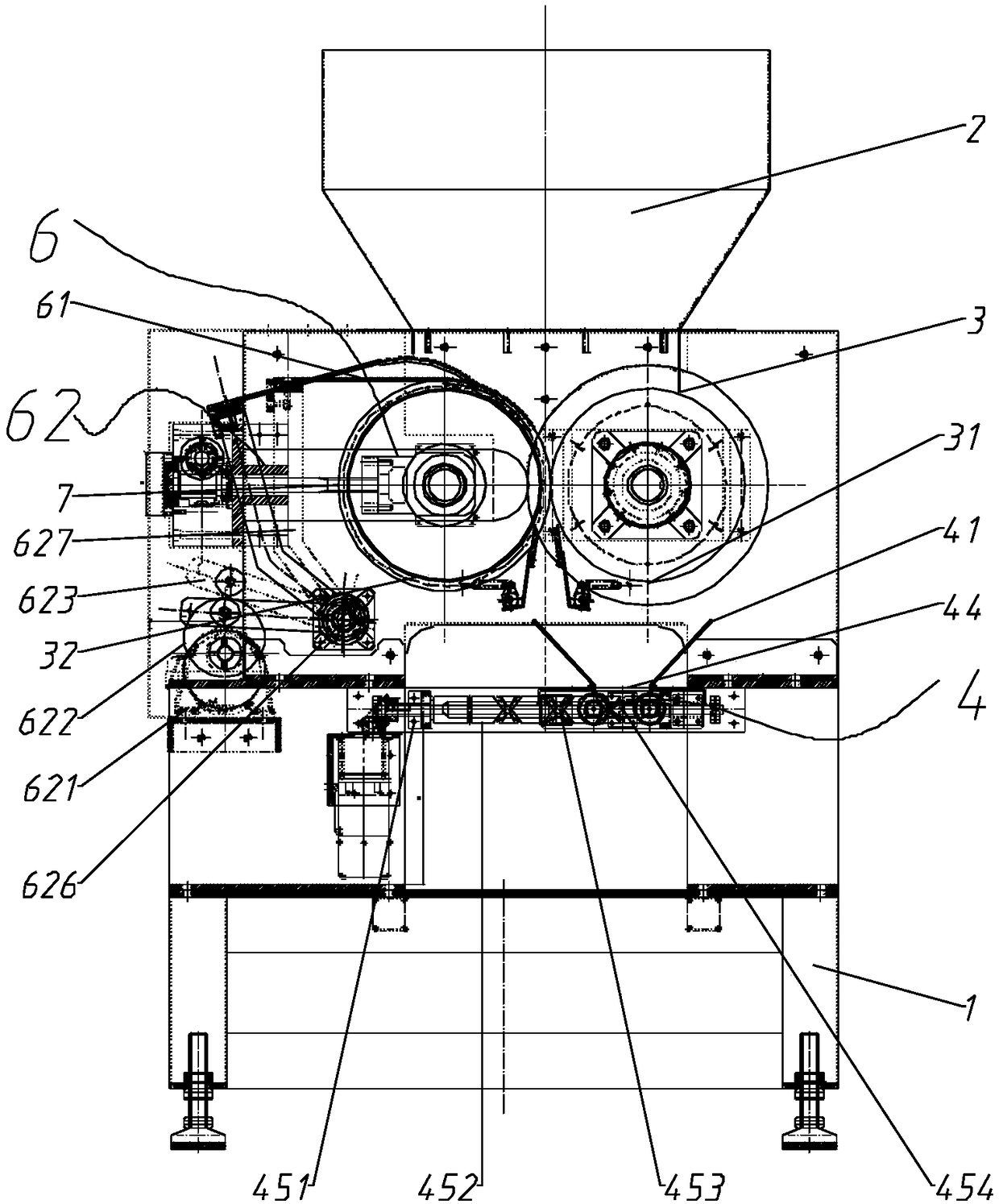

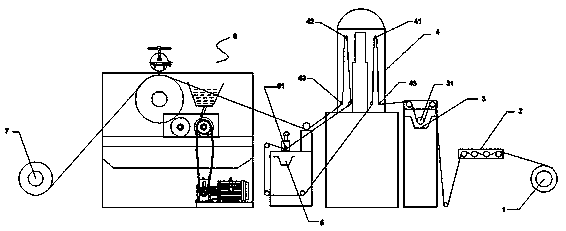

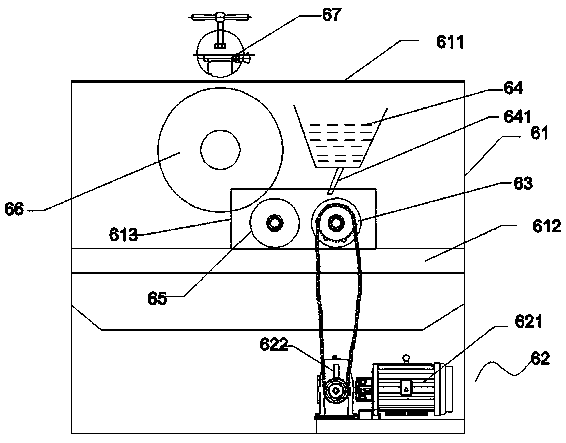

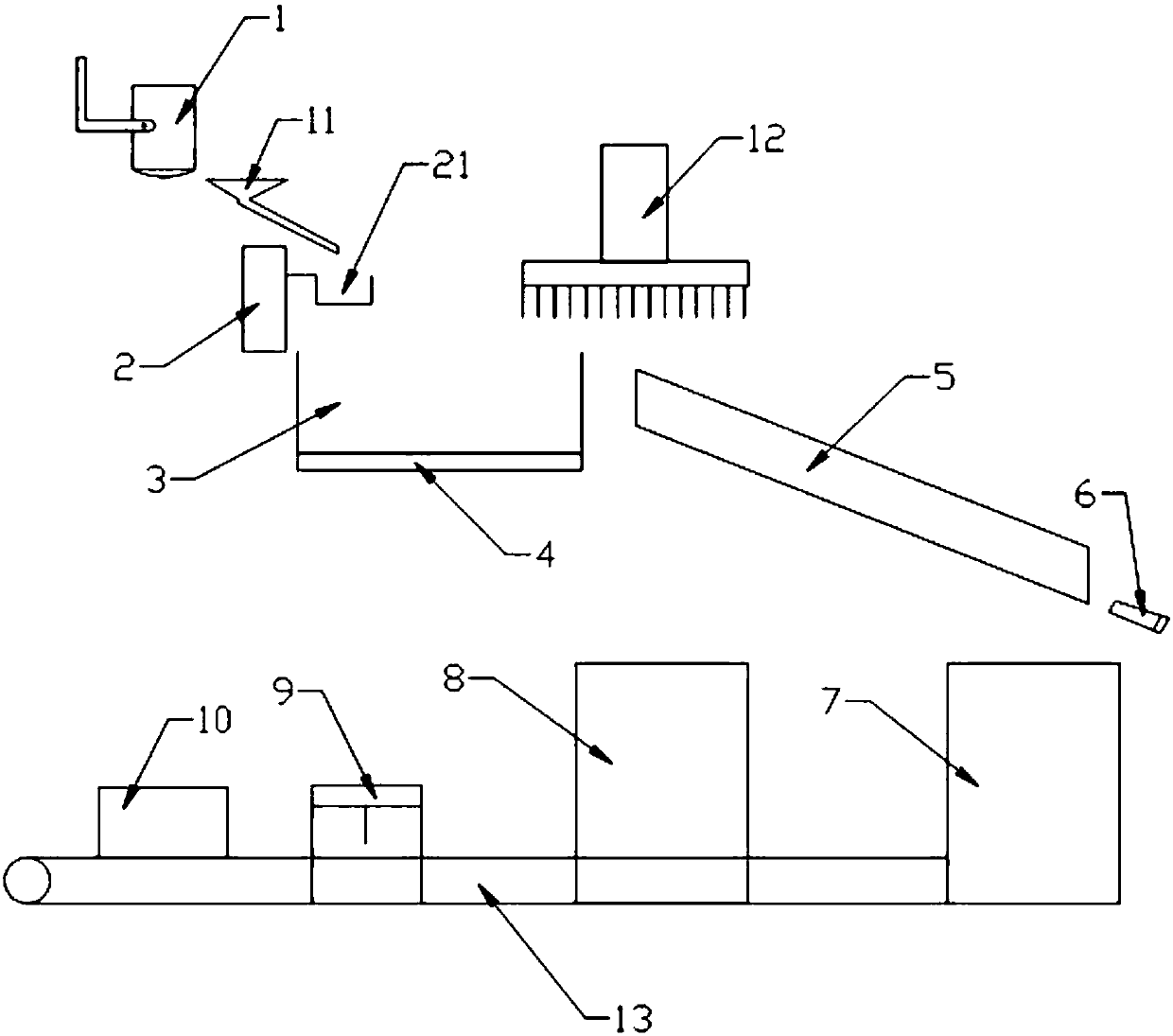

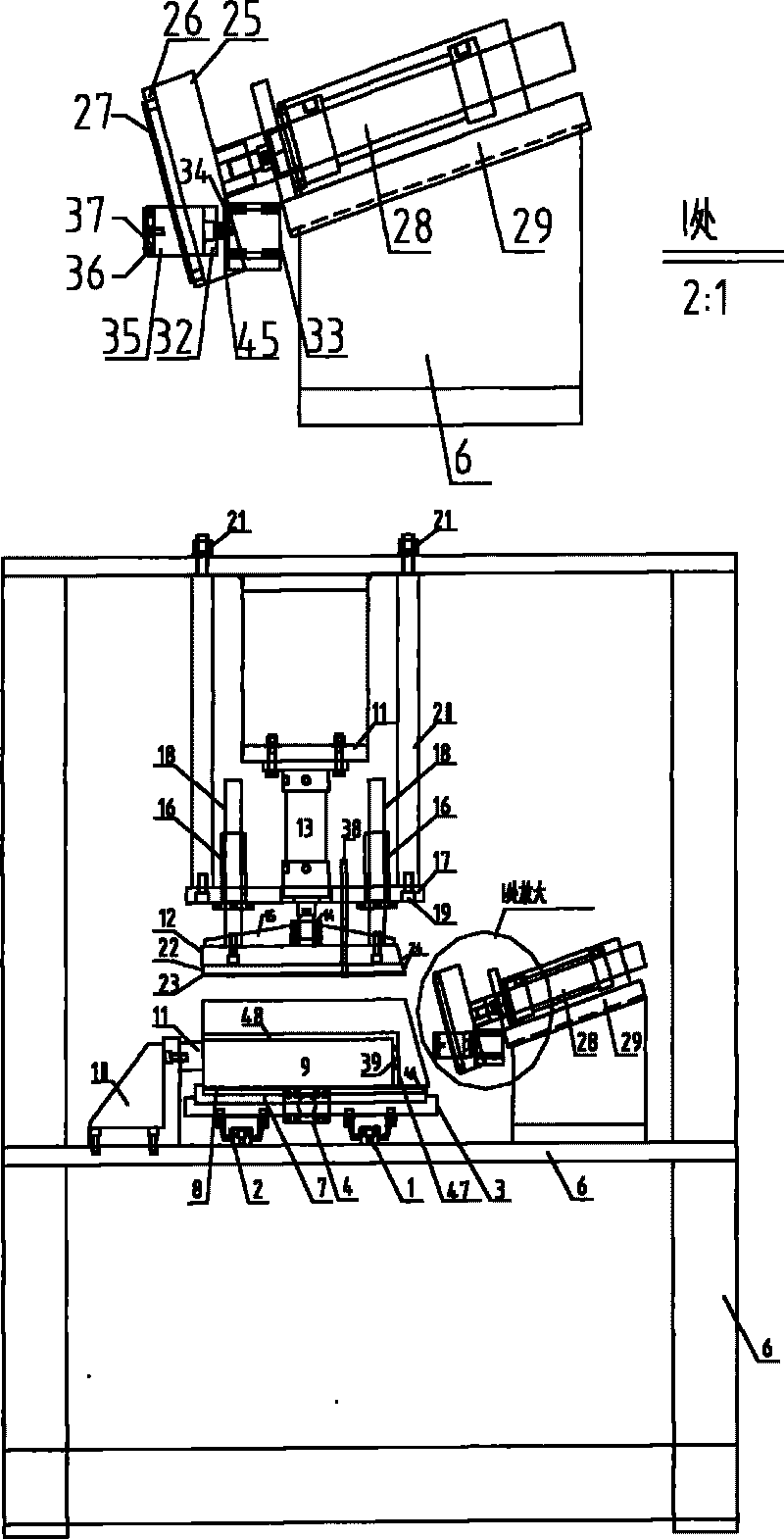

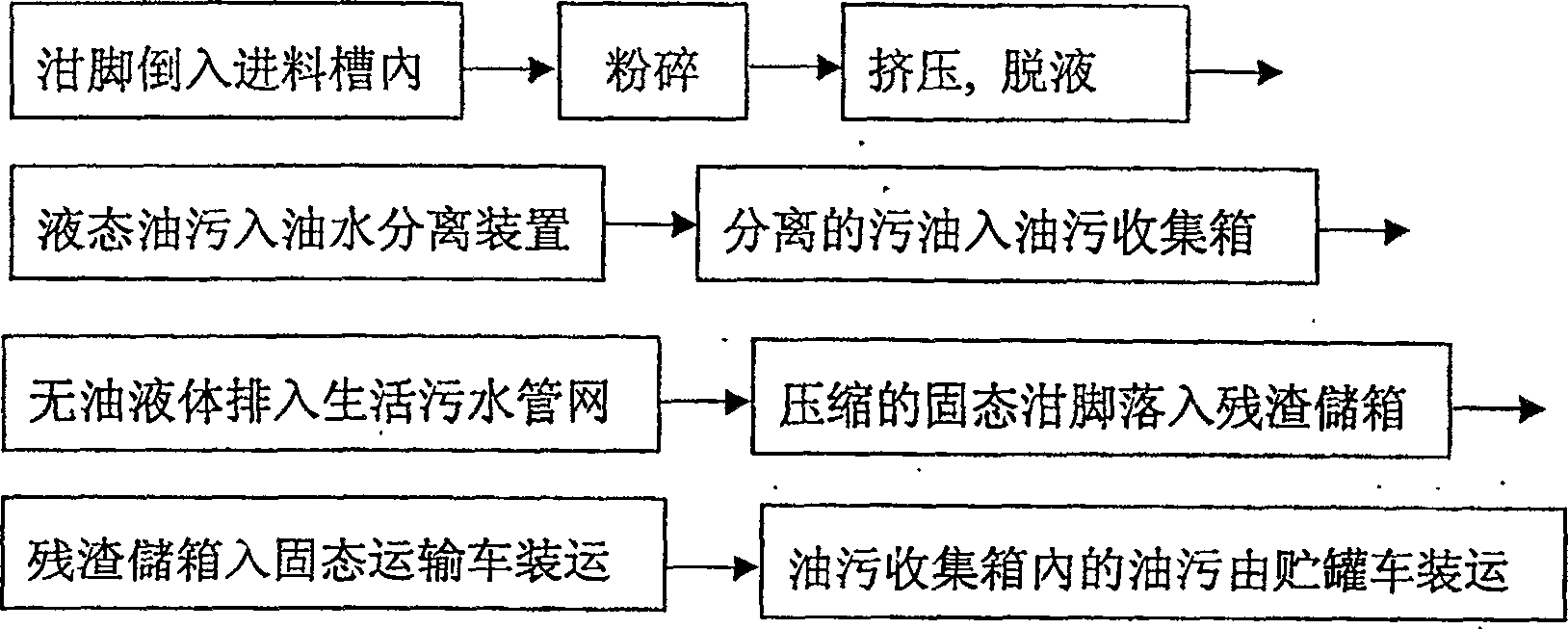

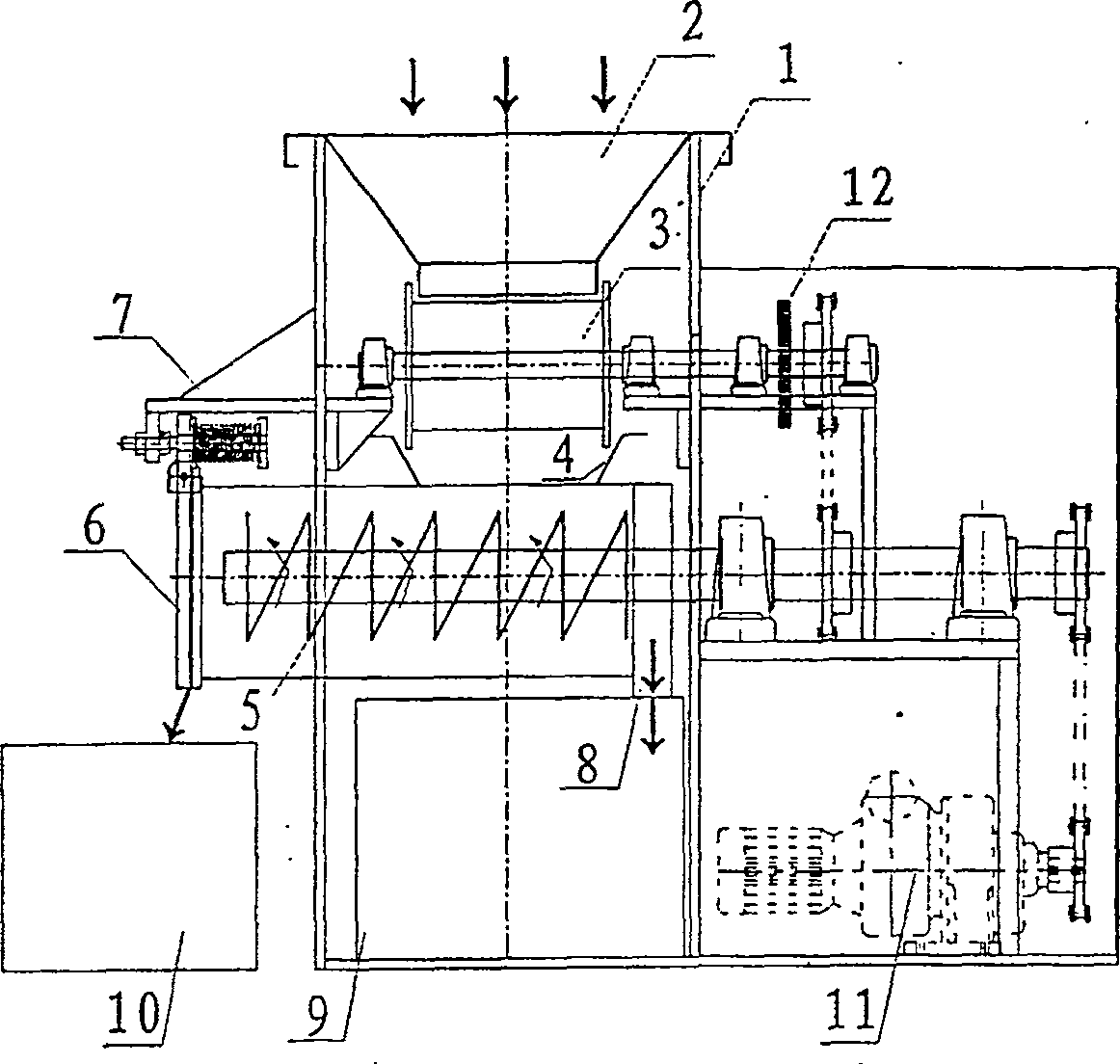

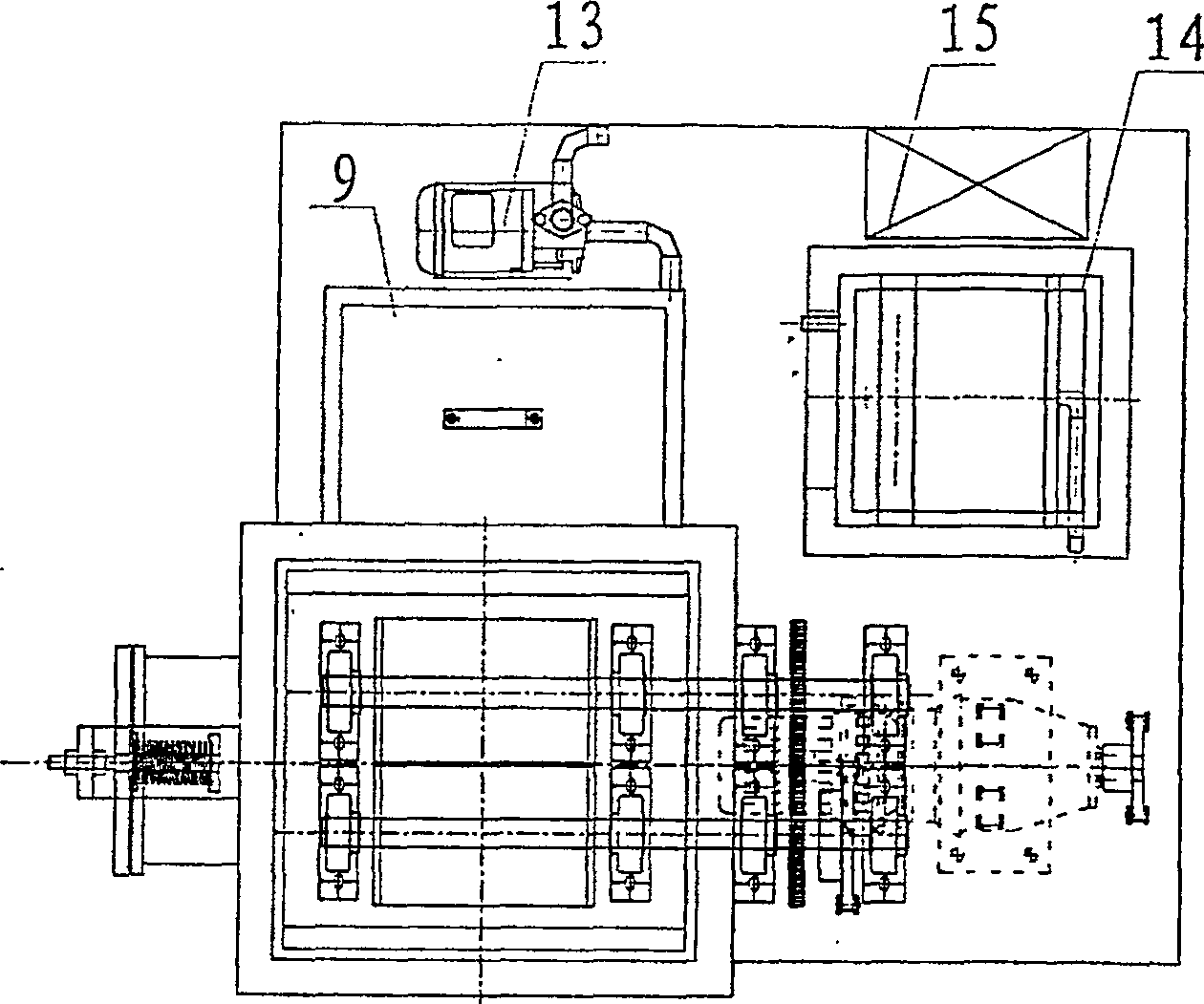

Pretreatment method and treating machine for hogwash refuse of kitchen

InactiveCN1879980AReduce transport volumeAvoid pollutionSolid waste disposalElectricityPretreatment method

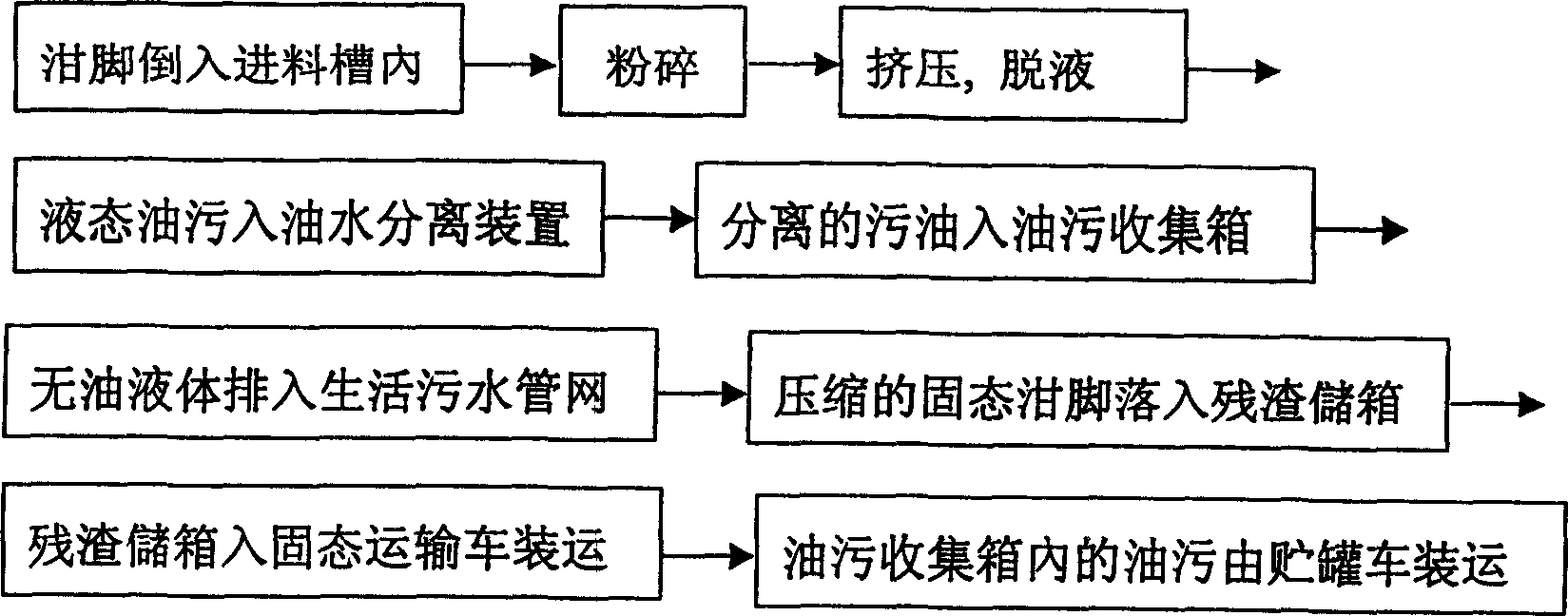

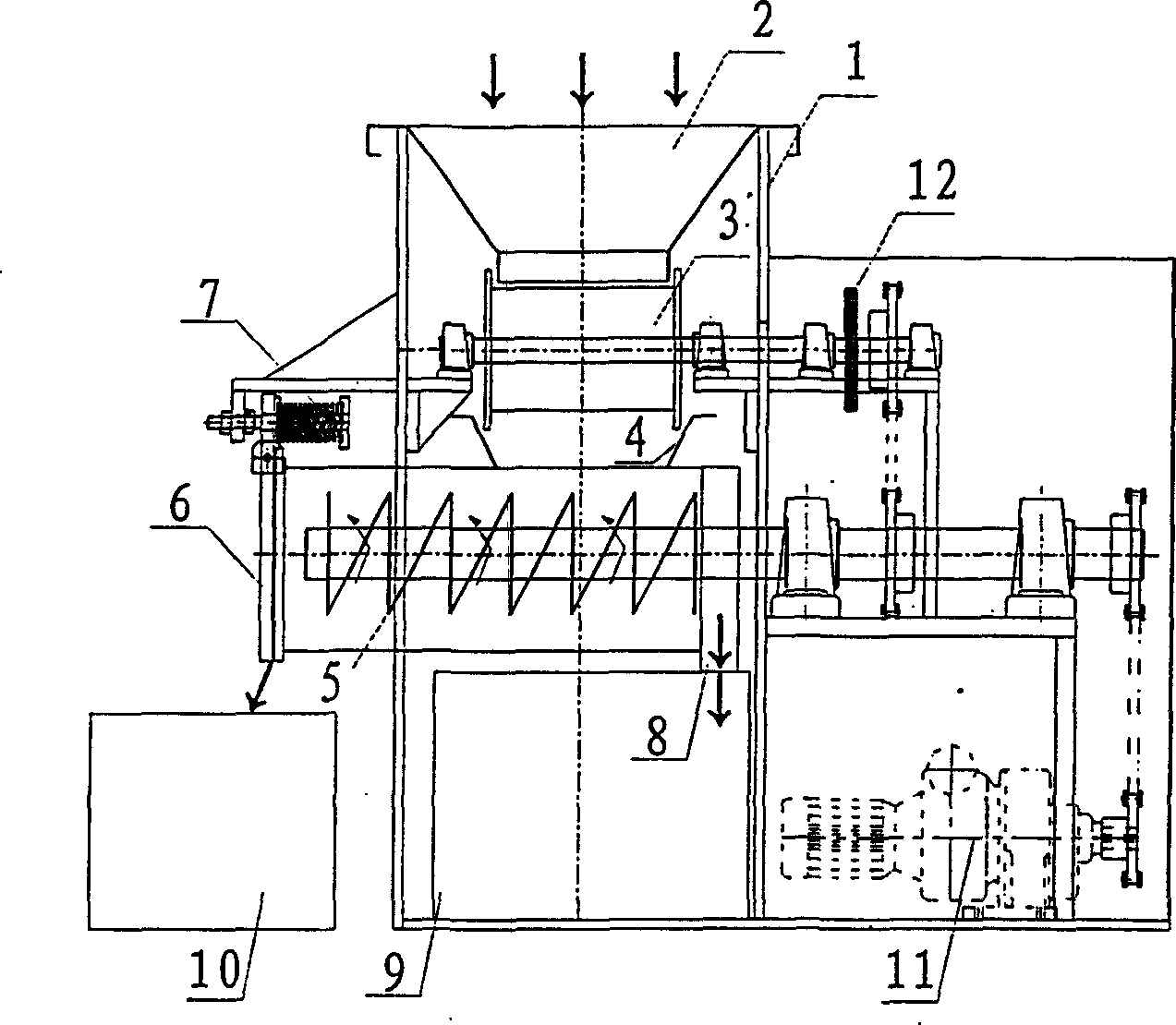

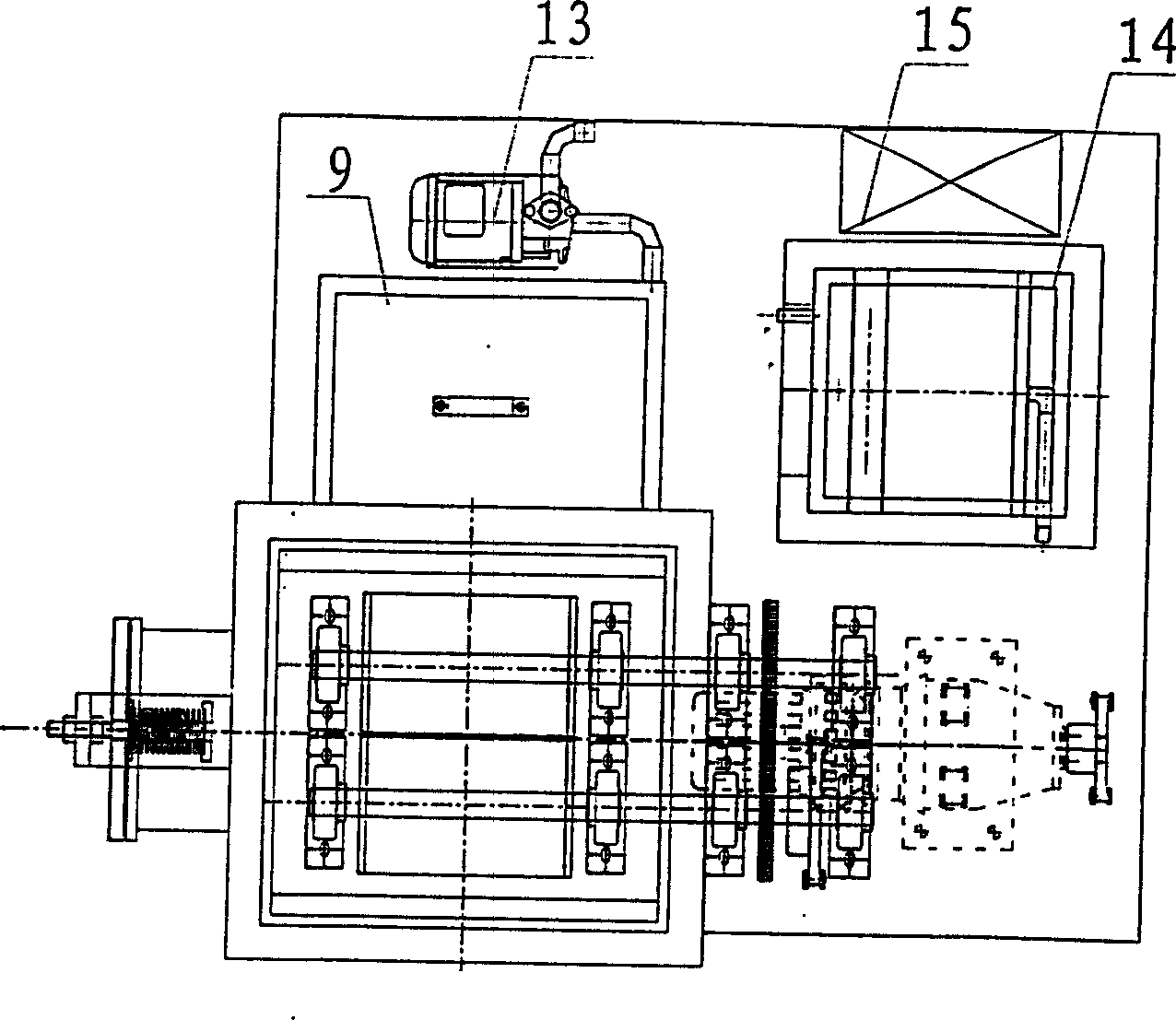

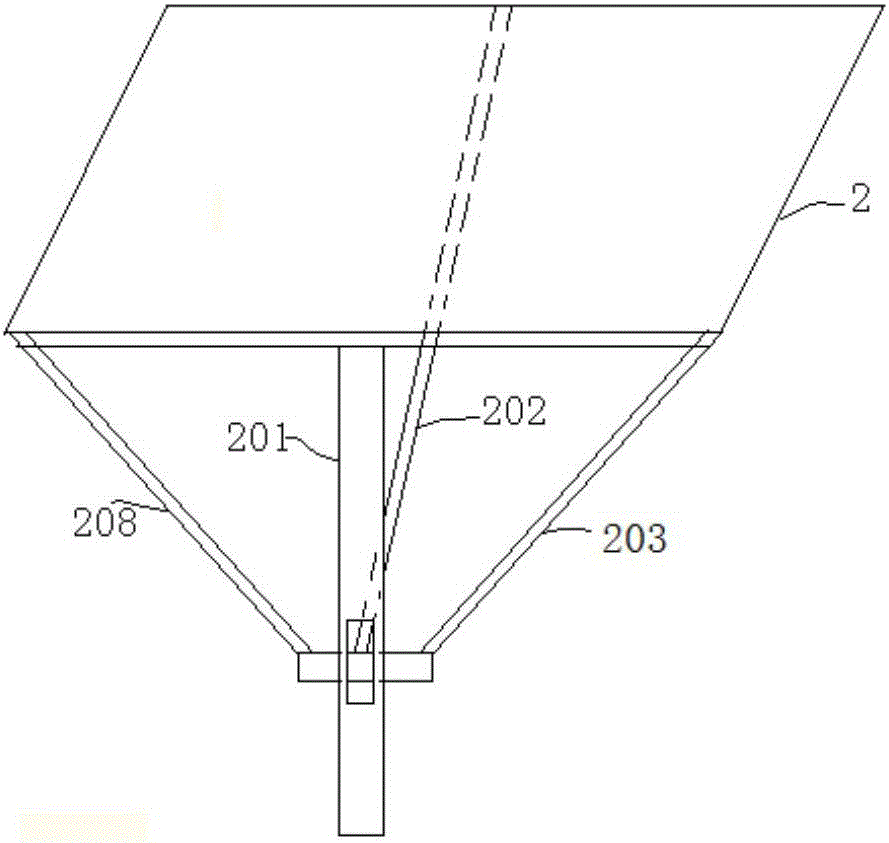

The invention relates to a pretreatment of kitchen garbage waste, and relative processor, wherein it is characterized in that: said method separates the solid and liquid matters, which uses breaking, compressing, removing liquid removing oil, and dewatering; the oil is collected into oil collect tank; the non-oil liquid is fed into the life sewage tube network; the compressed solid garbage is fed into the slag storage tank to be stored in solid carrier; the oil is carried via storage carrier. The invention comprises two meshed rolling tooth wheels, whose meshed center is under the feeding groove and under the broken guide groove; and it comprises a compress baffle plate, an oil-water separator and an oil collecting tank. The invention has small volume, less electricity consumption and simple operation.

Owner:钟建成

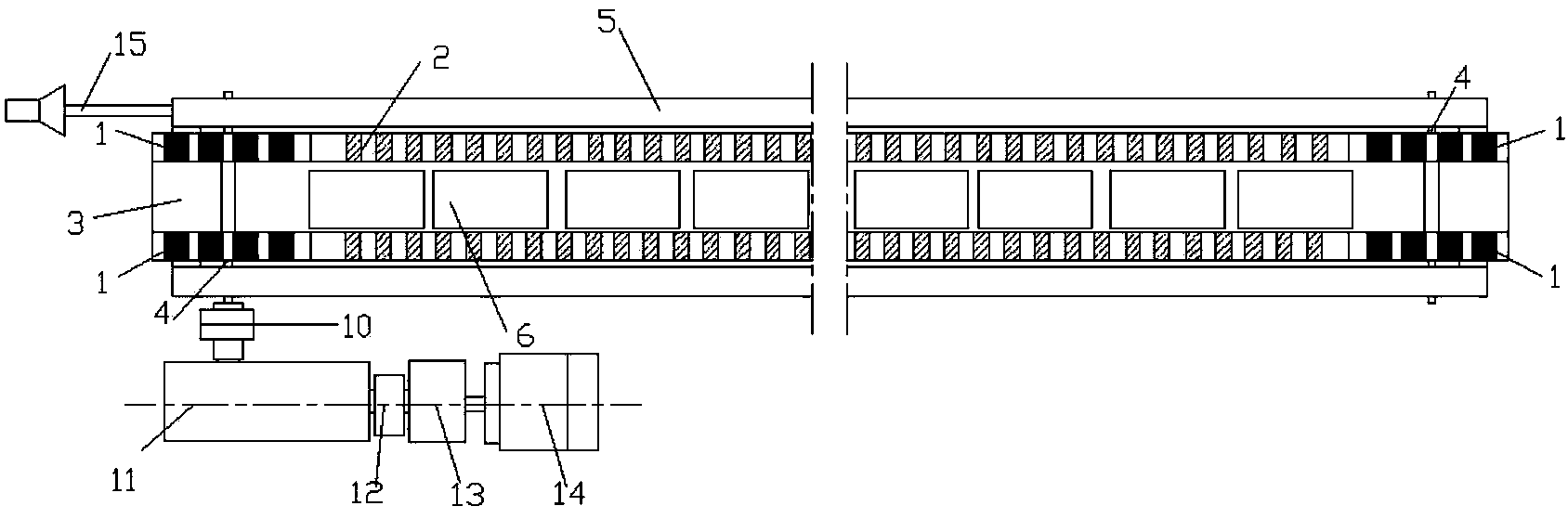

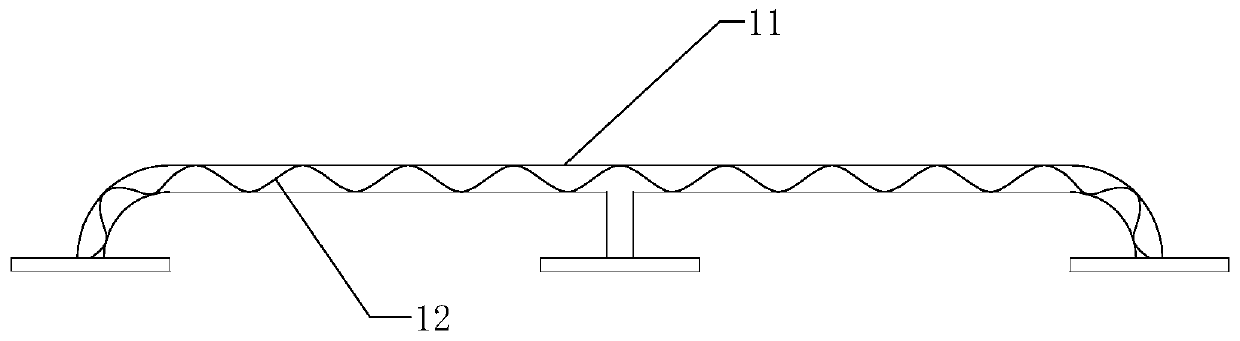

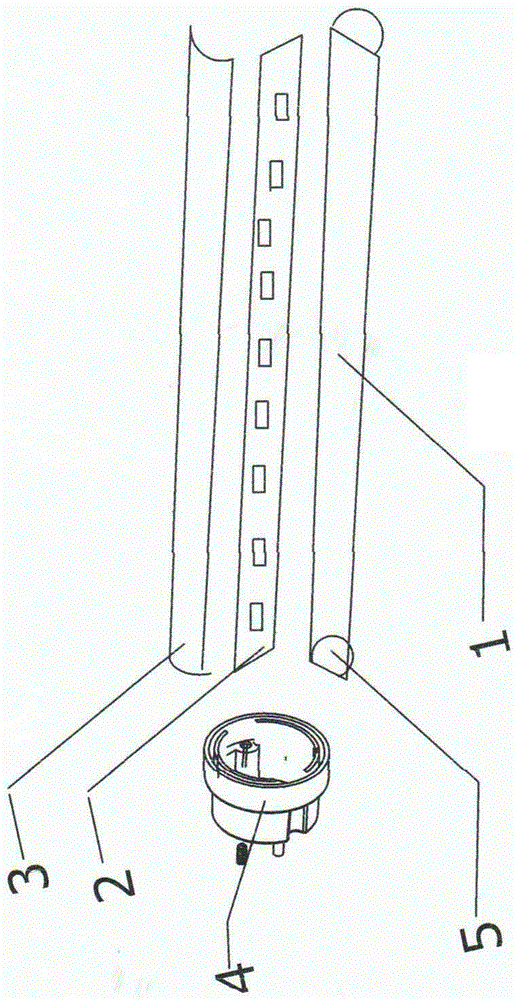

Magnetic levitation synchronous belt conveyor

InactiveCN103979251AMagnetic hasSuitable for production useNon-mechanical conveyorsDrive shaftEngineering

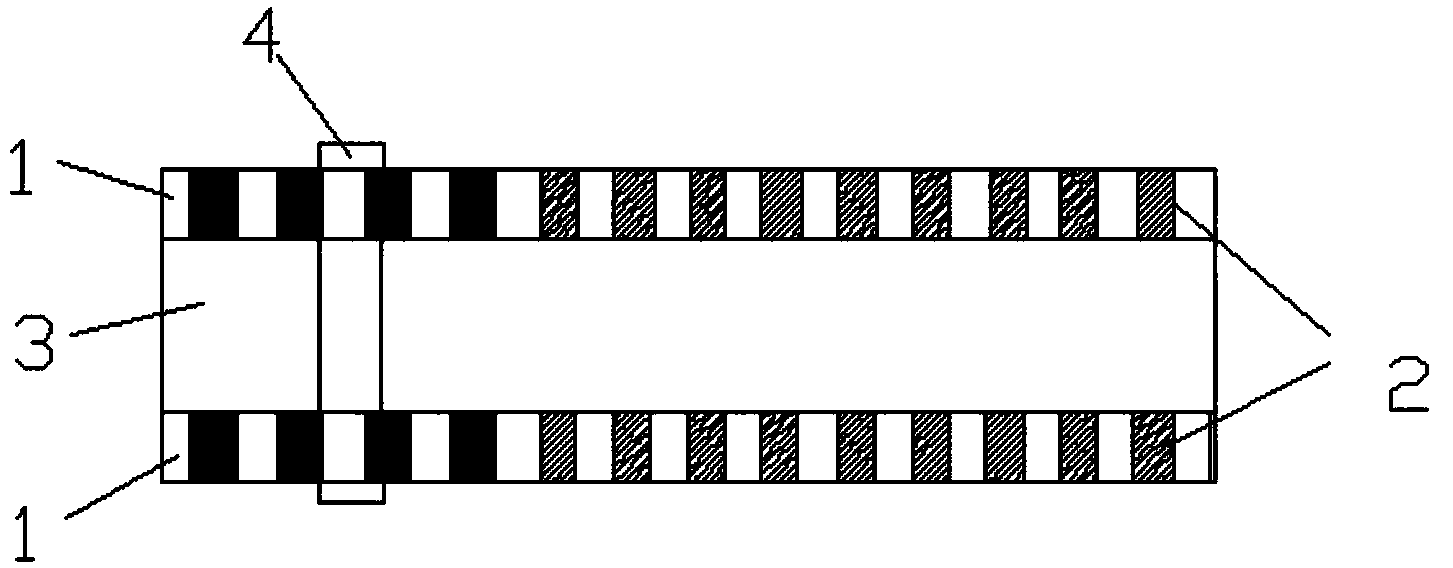

A magnetic levitation synchronous belt conveyor comprises a driving device, a transmission shaft, synchronous belt wheels, a magnetic conveying belt-permanent magnet suspension supporting device, a machine frame and a return roller. The driving device is connected with the transmission shaft which is provided with the two synchronous belt wheels in parallel. Synchronous belts are wound on the two synchronous belt wheels which are arranged in parallel respectively. The two synchronous belts are fixed at the edge of the inner surface of a conveying belt and are arranged in parallel. Permanent magnets are fixed at the center line of the inner surface of the conveying belt and are arranged at equal distance in the conveying direction on the inner surface of the conveying belt. A permanent magnet supporting device is fixed on the machine frame and replaces an upper roller support of a common belt type conveyor. According to the magnetic levitation synchronous belt conveyor, the conveying belt has magnetism, system manufacturing cost and maintaining cost are low, deviation and slipping cannot happen, operation resistance is low, efficiency is high, energy loss is low, operation is stable, noise is low, and high-speed operation can be achieved.

Owner:ANHUI UNIV OF SCI & TECH

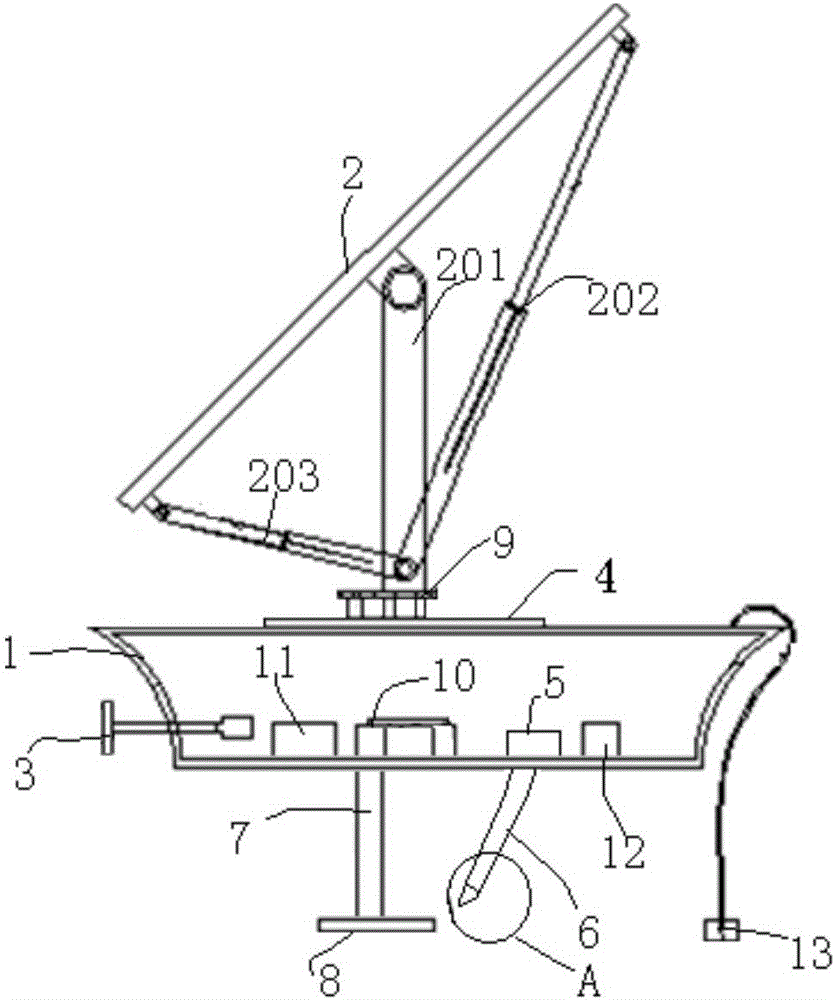

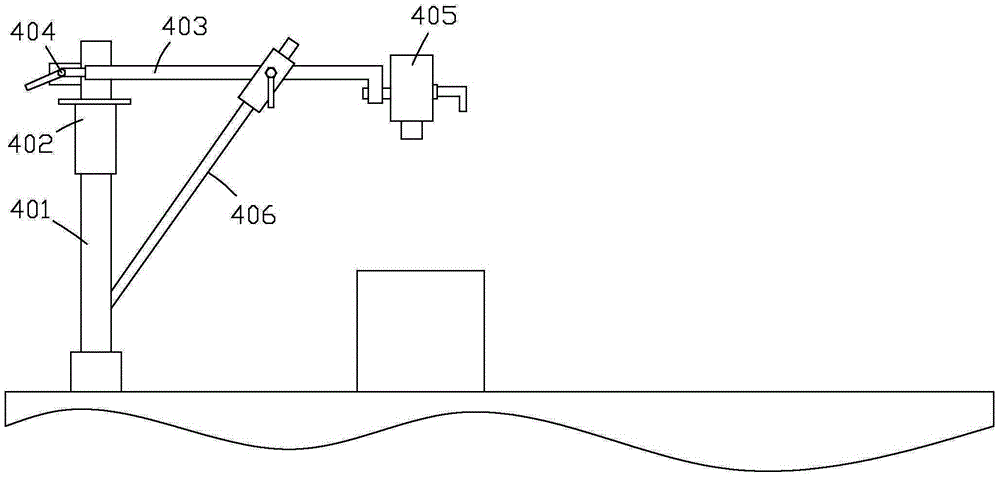

Solar aerating vessel for fishpond farming

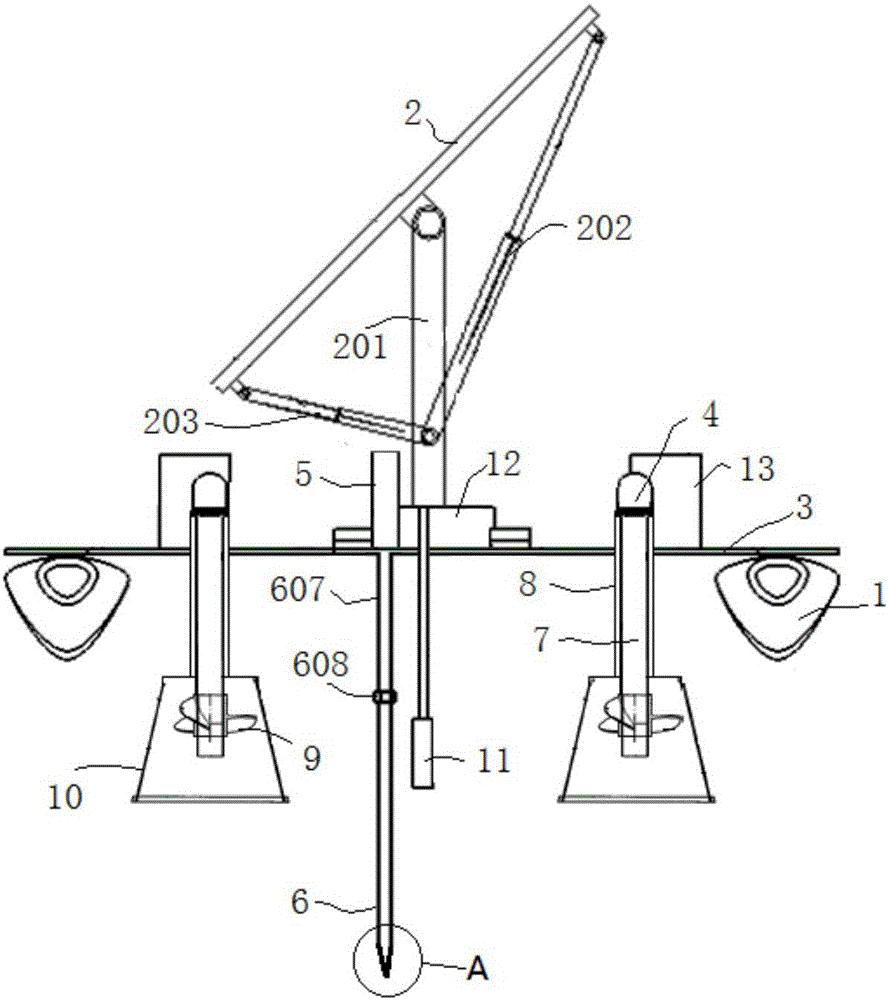

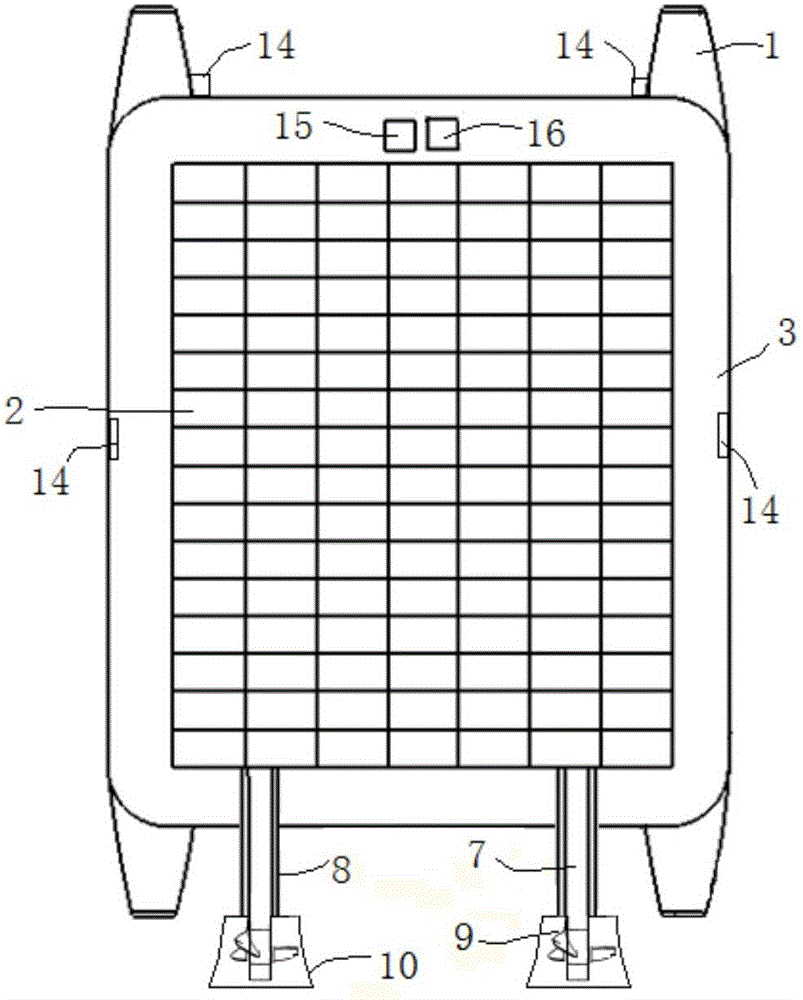

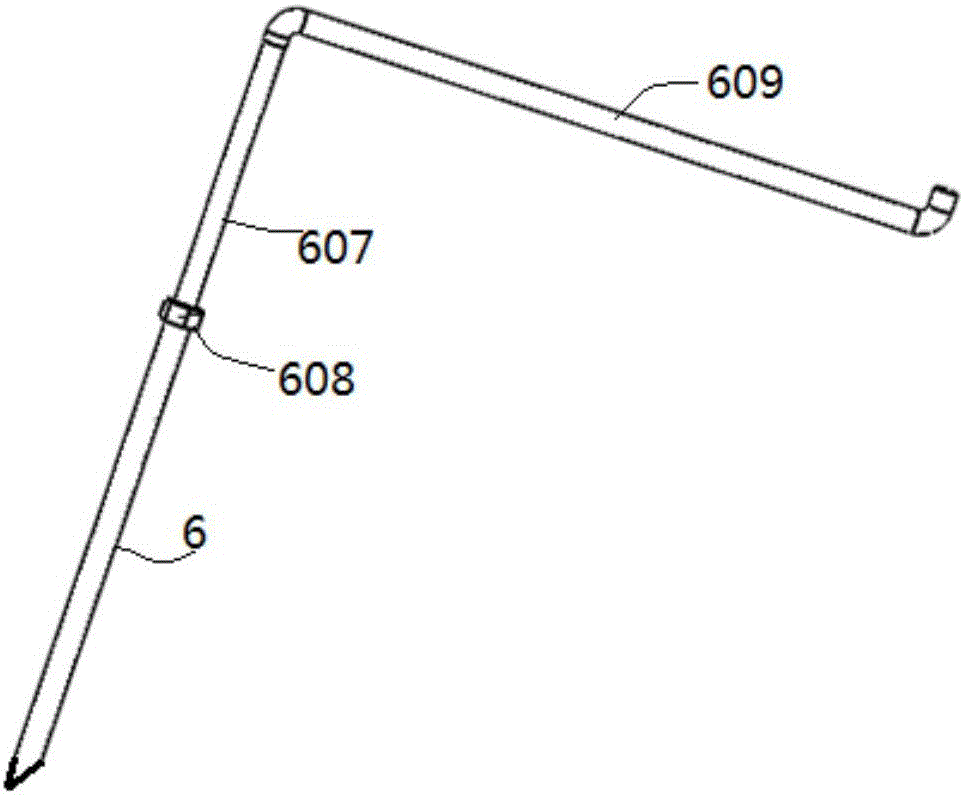

ActiveCN106275297ARealize autonomous mobile oxygen enrichmentOxygen balancePhotovoltaic supportsEnergy supplyOxygen sensorDrive shaft

The invention discloses a solar aerating vessel for fishpond farming, and belongs to the field of fishery breeding. The solar aerating vessel comprises a hull and a deck, wherein a solar power supply mechanism is arranged on the deck; an aerating mechanism, a navigation mechanism and storage batteries are arranged in the hull; the aerating mechanism comprises a transmission shaft and an air pump; a propeller is arranged at the bottom end of the transmission shaft; thrusters are arranged at the tail part of the hull, and connected with the storage batteries; a dissolved oxygen sensor is arranged at the front end of the hull, and the dissolved oxygen situation in water is detected through the dissolved oxygen sensor; electric energy produced by a solar panel is stored in the storage batteries for providing the electric energy for the thrusters, the aerating mechanism and the navigation mechanism. The solar aerating vessel for the fishpond farming uses solar energy as a power system, is rich in resources and free of pollution, can perform mobile uniform aeration, and has a high oxygen dissolving efficiency.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Movable solar oxygenation system and oxygenation method

ActiveCN106342744AOxygen evenlyRealize mobile oxygenationPisciculture and aquariaDrive motorSolar power

The invention discloses a movable solar oxygenation system and method and belongs to the field of fishery culture. The oxygenation system comprises a buoyancy supporting mechanism, a solar power supply mechanism, a power mechanism, an oxygenation mechanism, a hoisting mechanism and a control mechanism, wherein the control mechanism comprises a central controller, and a dissolved oxygen sensor, an ultrasonic range finding module, a GPS (Global Positioning System) navigation module and an inertial navigation module, which are electrically connected with the central controller respectively; the central controller is used for controlling rotary speeds of two driving motors according to information fed back by the ultrasonic range finding module, the GPS navigation module and the inertial navigation module, so that movable oxygenation and automatic berthing are realized; electric energy generated by the solar power supply mechanism is stored in the storage battery and is used for providing the electric energy to the oxygenation mechanism, the power mechanism and the control mechanism. According to the movable solar oxygenation system and method, intelligent and flexible movement of the oxygenation system can be realized; the dissolving efficiency of oxygen in water can be effectively enhanced and the utilization performance of whole equipment is improved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Method for producing concentrated inactivate vaccine for newcastle disease

ActiveCN101474401AGood concentration and stabilityHigh potencyViral antigen ingredientsAntiviralsAnti virusAntigen

The invention provides a method for producing improved concentrated inactivated vaccine against Newcastle disease. The method comprises the steps of virus inoculation passage, ultrafiltration and concentration, mixing water phase and oil phase and the like, wherein, a 30KD membrane is used for ultra-filtrating and concentrating, and the concentrated water phase and oil phase are mixed and emulsified in the proportion of 1 to 1 in a high pressure emulsification pump. The invention uses ultrafilter membrane concentration and antigen ingredient instead of the content of live virus, so that the chicken can produce strong immunity after being immunized by the vaccine for 10 to 14 days; the immunity period is 10 months; the anti-virus protective rate is 100 percent within the immunity period; and the invention has wide application prospect.

Owner:RINGPU (BAODING) BIOLOGICAL PHARMACEUTICAL CO LTD

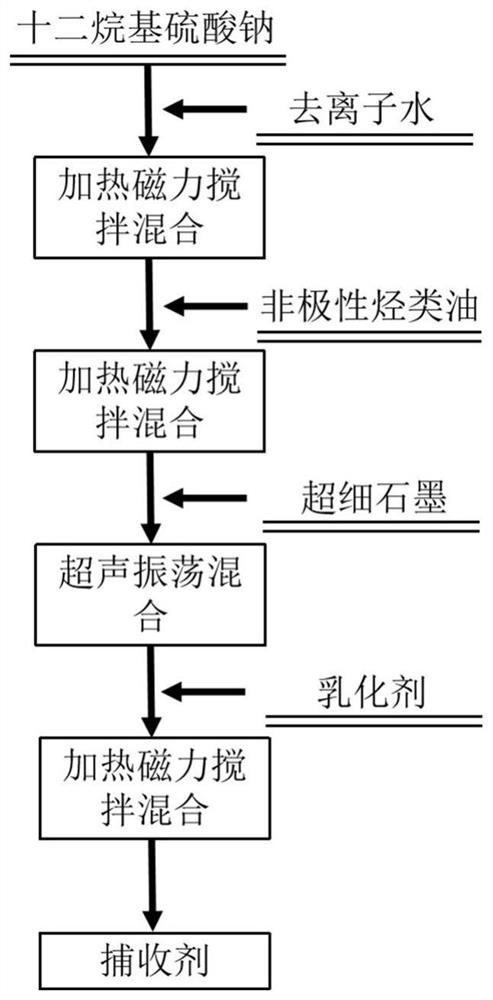

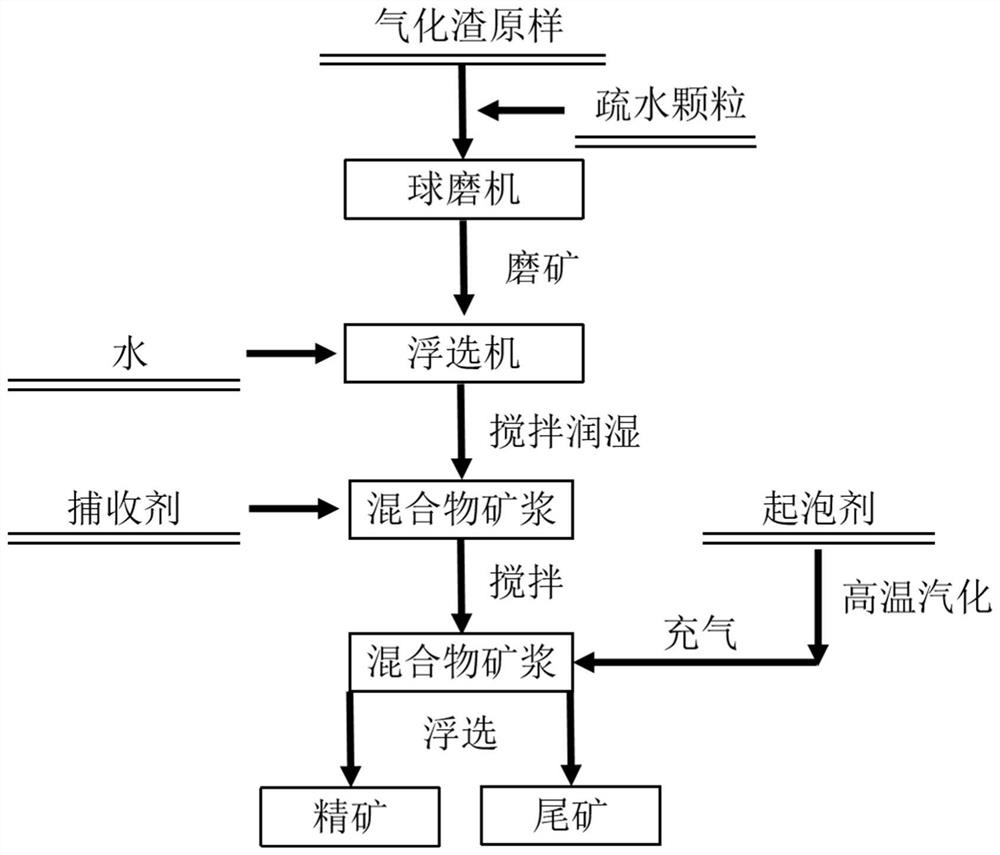

Gasified slag flotation collecting agent and preparation method thereof

The invention relates to the technical field of gasified slag flotation, in particular to a gasified slag flotation collecting agent and a preparation method thereof. The collecting agent comprises 1-3 parts by weight of lauryl sodium sulfate, 1-5 parts by weight of deionized water, 15-60 parts by weight of non-polar hydrocarbon oil, 1 / 10-1 / 2 parts by weight of hydrophobic particles and 1-3 parts by weight of an emulsifier, and the hydrophobic particles are graphite particles with the diameter of 1-2 microns. According to the prepared gasified slag collecting agent, lauryl sodium sulfate and non-polar hydrocarbon oil are mixed and compounded, the adsorption effect of the agent on the residual carbon surface of gasified slag can be improved, meanwhile, hydrophobic particles are added to enter pores in the surface of the gasified slag for filling in the flotation process, the agent is prevented from entering the pores, the utilization rate of the agent is increased, the flotation cost is reduced, and the flotation efficiency is improved.

Owner:CHINA UNIV OF MINING & TECH

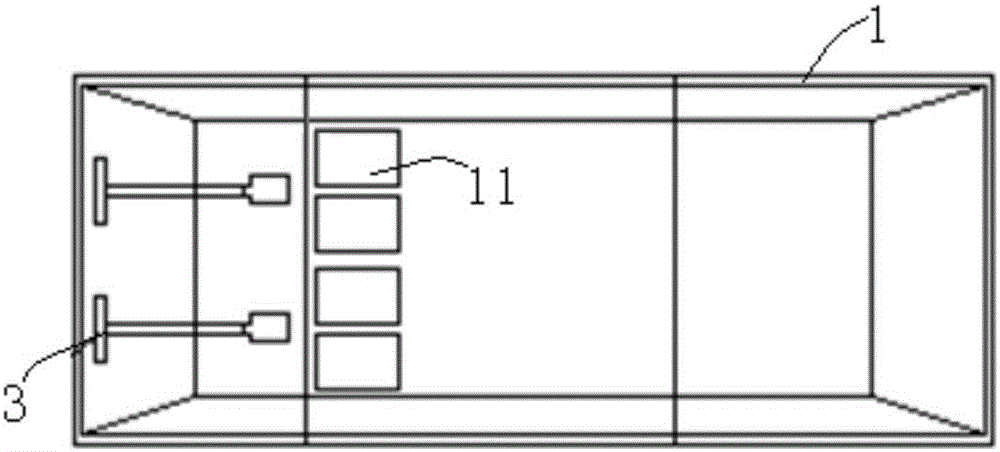

Workshop seawater circulating aquaculture and seedling culture system

A workshop seawater circulating aquaculture and seedling culture system comprises a water purification treatment device, a water temperature adjustment device, an oxygenation device and an aquaculture device, wherein the water purification treatment device, the water temperature adjustment device, the oxygenation device and the aquaculture device are connected in sequence through water pipes; the aquaculture device is connected with the water purification treatment device through a water pipe; the water purification treatment device comprises a rough filtration sediment box, a biofiltration box, a foam separator, a high-efficiency filter and a fresh seawater supplement device, and the rough filtration sediment box, the biofiltration box, the foam separator, the high-efficiency filter and the fresh seawater supplement device are sequentially arranged in the water flow direction; the water temperature adjustment device comprises a heat source and a heat exchanger; the aquaculture device comprises a plurality of aquaculture and seedling culture boxes and bait mixing equipment, each aquaculture and seedling culture box comprises a water outlet and a water inlet, aquaculture water switching valves are arranged at the water outlets and the water inlets, the oxygenation device is connected with high-efficiency oxygenation units through oxygen delivery pipelines, the high-efficiency oxygenation units are installed in the aquaculture and seedling culture boxes, oxygen delivery electromagnetic valves are installed at the oxygen delivery pipelines, the bait mixing equipment comprises a plurality of bait mixing boxes, and the bait mixing boxes are connected with the aquaculture and seedling culture boxes through bait pipelines, pumps and bait switching valves.

Owner:QINGDAO HUITENG MACHINERY EQUIP

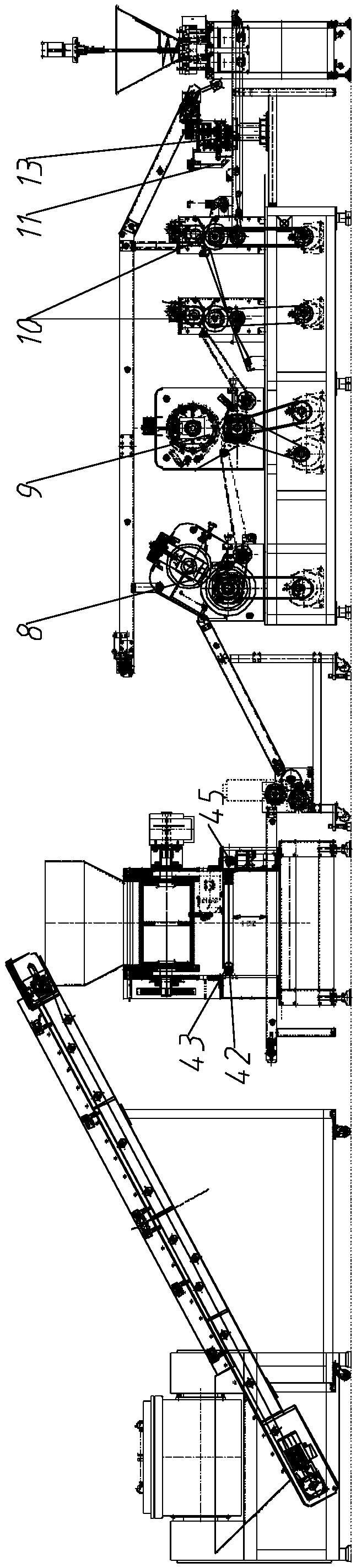

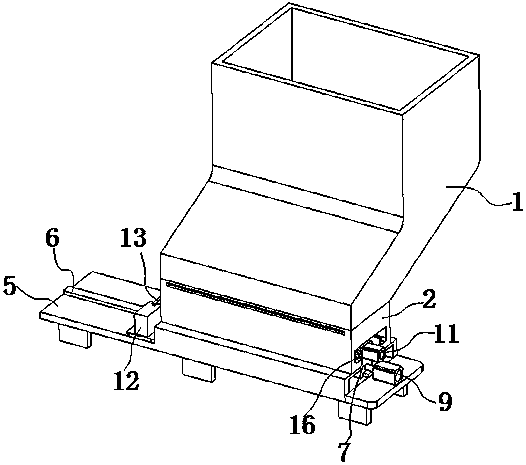

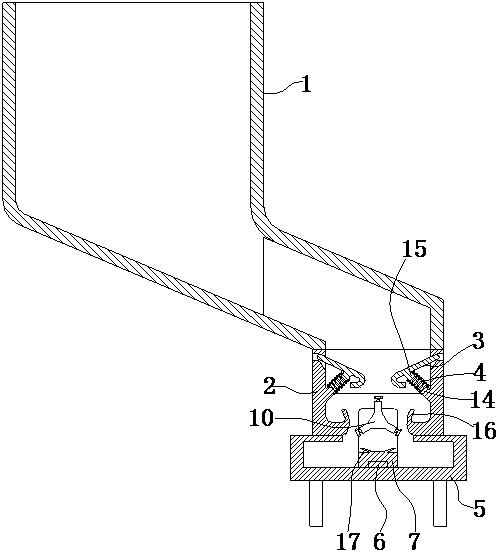

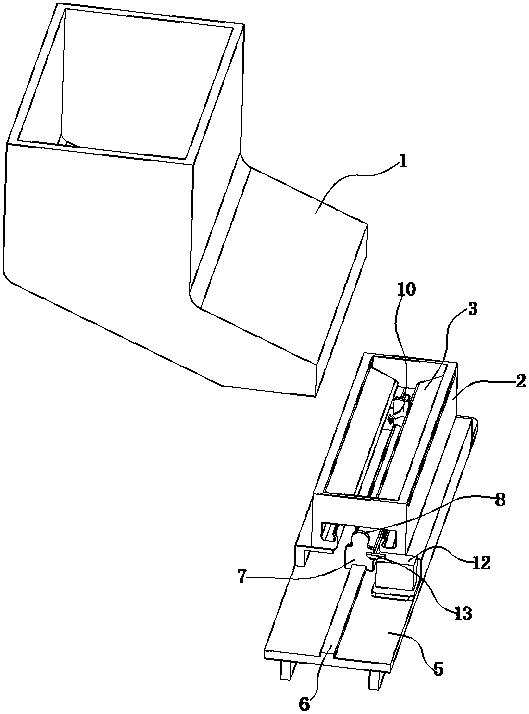

Wrapper making device and dumpling automatic making line

ActiveCN109362823AAvoid stuck damageImprove biteDough-sheeters/rolling-machines/rolling-pinsDough shaping and cutting apparatusProduction lineReciprocating motion

The invention belongs to the technical field of food processing, and provides a wrapper making device and a dumpling automatic making line. The wrapper making device comprises a machine frame, whereina feeding hopper, a wrapper making roller group, a wrapper piling device and a conveyer belt are sequentially arranged on the machine frame; an opposite pressing device is also arranged on the machine frame, and comprises lower pressing plates which are oppositely arranged; the lower pressing plates are located at one end close to the feeding hopper, of the wrapper making roller group, and are used for enabling dough to be extruded to be flat before the dough enters the wrapper making roller group; the wrapper piling device comprises a material guiding hopper which is in reciprocating motion;the moving direction of the material guiding hopper is perpendicular to the transporting direction of the conveyer belt; and wrappers pressed by the wrapper making roller group are subjected to positive and negative piling after being guided by the material guiding hopper. The invention further comprises a quick-frozen dumpling automatic production line. A rough pressing device, a beating device,a fine pressing device, a filling injecting device, a guiding device, a shaping device and a recovering device are sequentially arranged on the quick-frozen dumpling automatic production line. Through the adoption of the wrapper making device and the quick-frozen dumpling automatic production line disclosed by the invention, the problems that in the prior art, the speed of manually making dumplings is too low, and the requirements of people cannot be met are solved; and the technical problem that problems exist in some dumpling making machines, so that the dumpling making machines are difficult to popularize and use, is solved.

Owner:石家庄市汉普食品机械有限公司

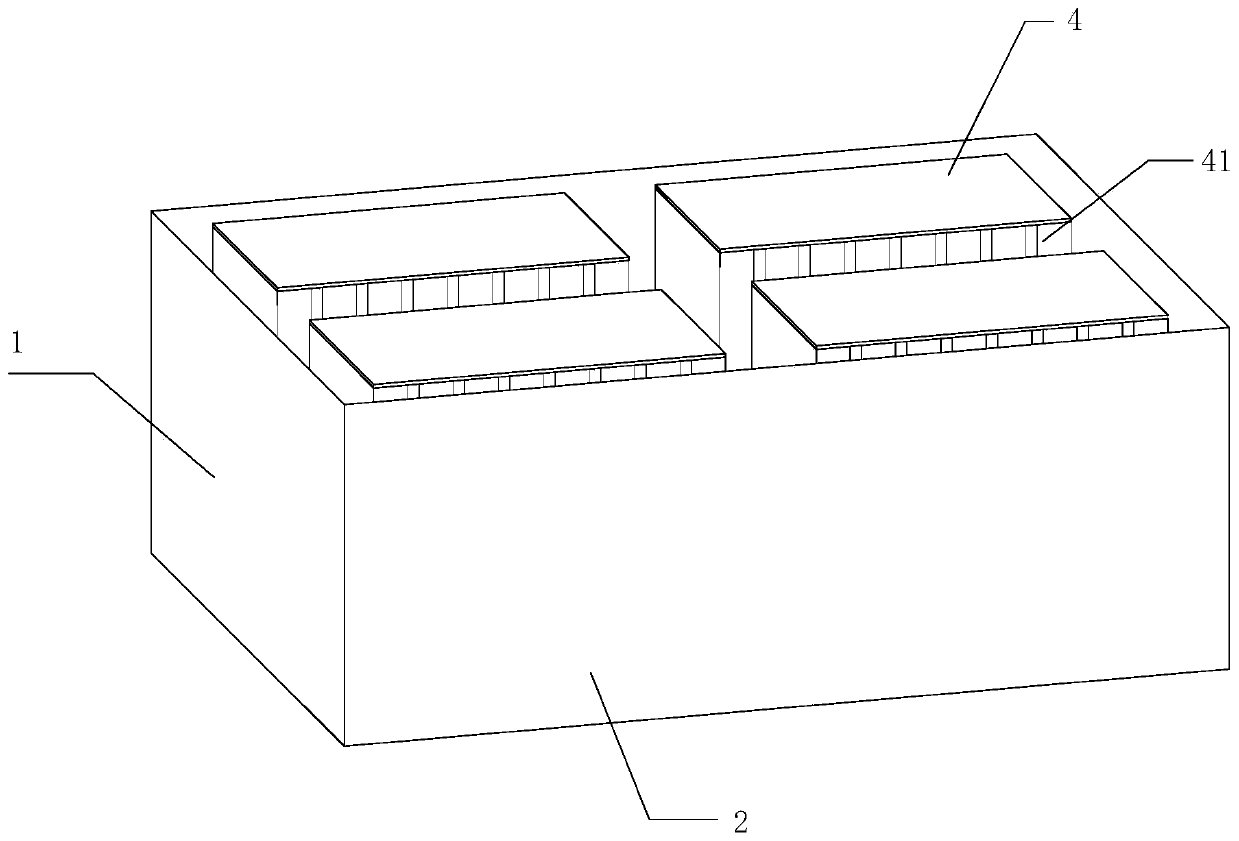

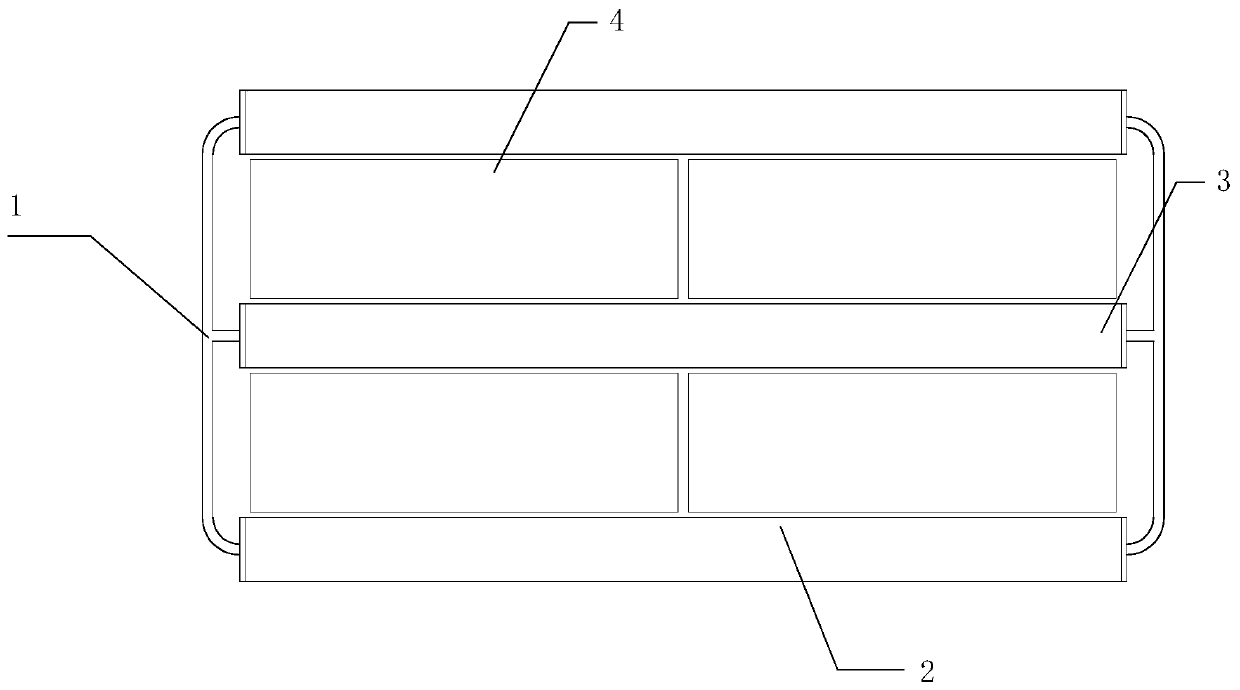

Novel energy-absorbing protective battery box

ActiveCN110391373AProtection securityAvoid deformationBattery isolationFire rescueIsosceles trapezoidEnergy absorption

The present invention provides a novel protective energy-absorbing battery box. The novel protective energy-absorbing battery box is formed by combining high-strength steel and sine wave rib plates, so that the novel protective energy-absorbing battery box is not easy to deform in the collision process of the battery box, and the sine wave rib plates can reduce the peak force in collision, the safety of the battery is protected, and the good collision resistance can be provided. An energy-absorbing column adopts a combination of a hexagonal honeycomb structure and a square structure. During crash crushing, the honeycomb structure absorbs a large amount of energy through plastic deformation. Meanwhile, the energy-absorbing column is also provided with the square structure, and a large number of corner units provided by the energy-absorbing column can absorb energy in the collision process, so that the safety of the battery is protected. A battery pressing plate is a sandwich structure,the inner layer is a self-similar structure consisting of an isosceles trapezoid and a rectangle, and the yield strength and the energy absorption capacity of the pressing plate can be adjusted by changing the number of self-similar layers and the self-similar proportion, so that the battery pressing plate has the good energy-absorbing performance. The protective energy-absorbing battery box can provide enough buffering energy absorption when collision occurs.

Owner:HUAQIAO UNIVERSITY

Zinc-nickel alloy electroplating process for metal surface

InactiveCN111058067AThe plating process is simpleImprove uniformityCellsElectrogalvanizationWater flow

The invention discloses a zinc-nickel alloy electroplating process for a metal surface, and relates to the technical field of electroplating, wherein the zinc-nickel alloy electroplating process comprises the steps of raw material inspection, chemical oil removal, primary water washing, electrochemical oil removal, secondary water washing, polishing, pickling, hanging, zinc-nickel alloy electroplating, quaternary water washing, drying and detection packaging. The chemical oil removal comprises the steps of treating grease on the surface of a metal component by alkali liquor with saponificationeffect to remove saponifiable grease; primary water washing comprises the steps of washing the metal component subjected to oil removal in the step S2 by flowing hot water flow. According to the zinc-nickel alloy electroplating process, based on the original process, the stirring device is additionally arranged, on one hand, the uniformity and speed of mass transfer in electroplating can be improved, on the other hand, the problem that the thickness of a plating layer is easily increased in a high-current area can be prevented; in addition, the electroplating process of the zinc-nickel alloyelectroplating process is simple, the electroplating effect of the metal surface is improved, and the electroplating cost is effectively reduced.

Owner:TIANJIN DAGANG GALVANIZED FACTORY

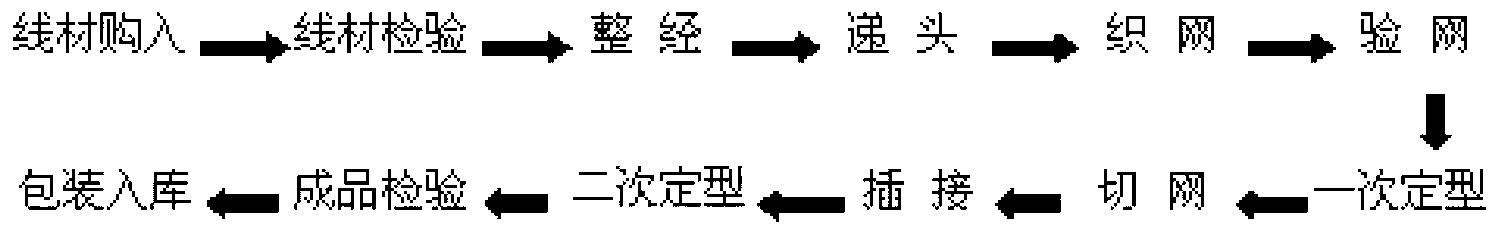

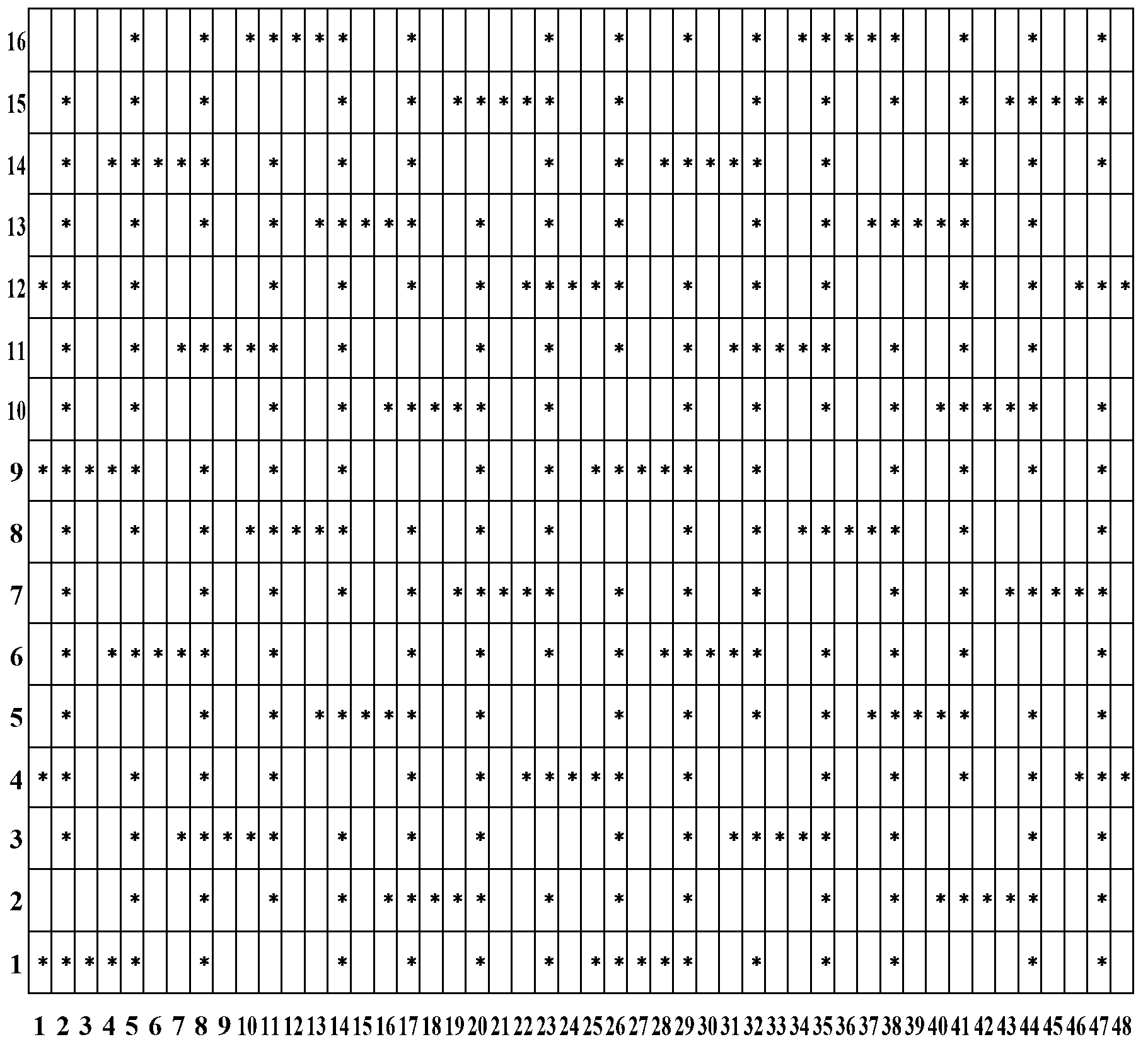

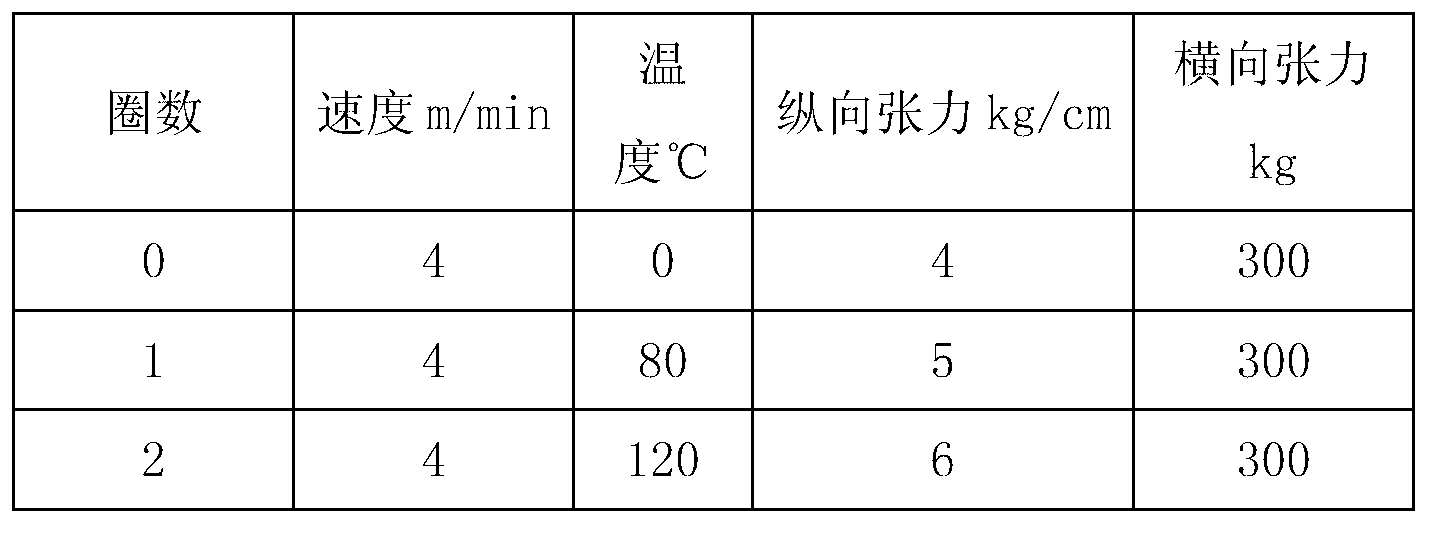

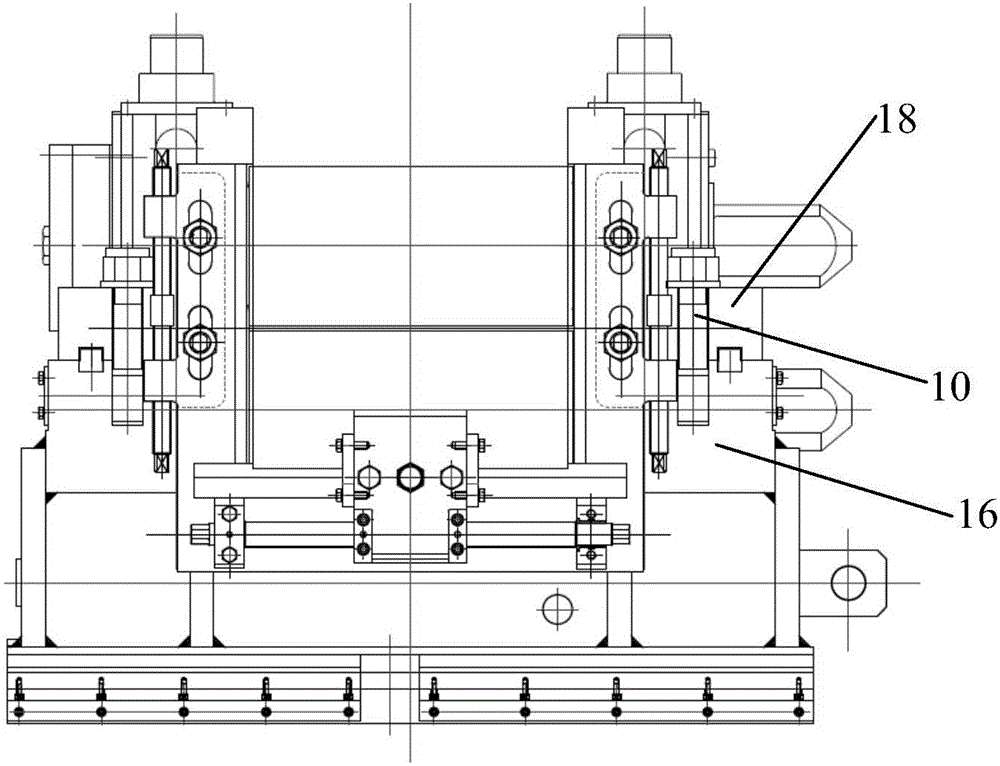

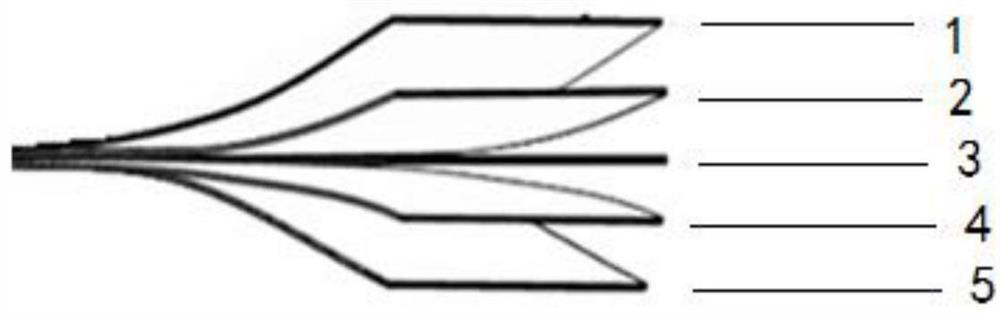

Production process of multi-layer pulp washing net

ActiveCN103290717AImprove stabilityExtended service lifeMachine wet endMulti-ply fabricsWear resistantProduct inspection

The invention discloses a production process of a multi-layer pulp washing net. The production process includes the steps of filament purchasing, filament inspection, warping, healding, net weaving, net checking, primary shaping, net cutting, plugging connection, secondary shaping, finished product inspection, packaging and warehousing, and the like. A texture structure of 2.5 layers is adopted, and retention of pulp is guaranteed; the multi-layer pulp washing net is woven by 16 healds, long in bottom weft, large in floating length, wear-resistant and long in service life; the multi-layer pulp washing net is compact in net body structure, stable, regular and even in mesh, not easy to deform, capable of guaranteeing excellent dehydration and suitable for production and use of large-weight pulp boards and high-speed pulp machines.

Owner:ANHUI PACIFIC SPECIALITY FABRIC

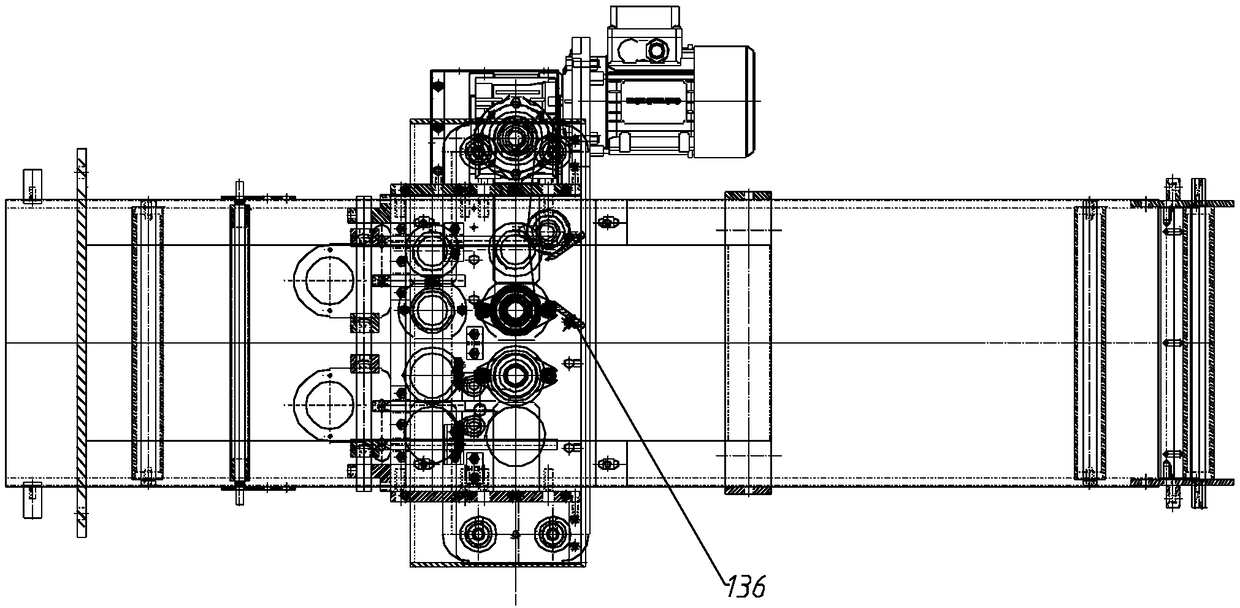

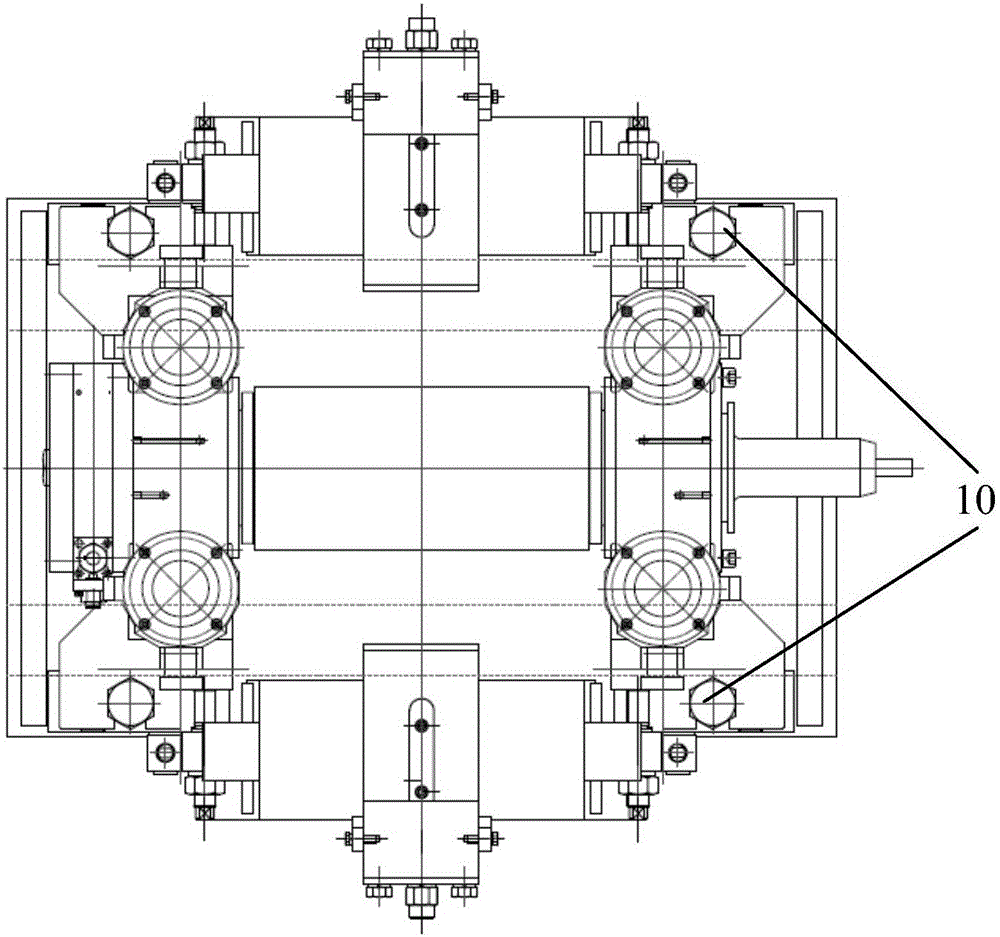

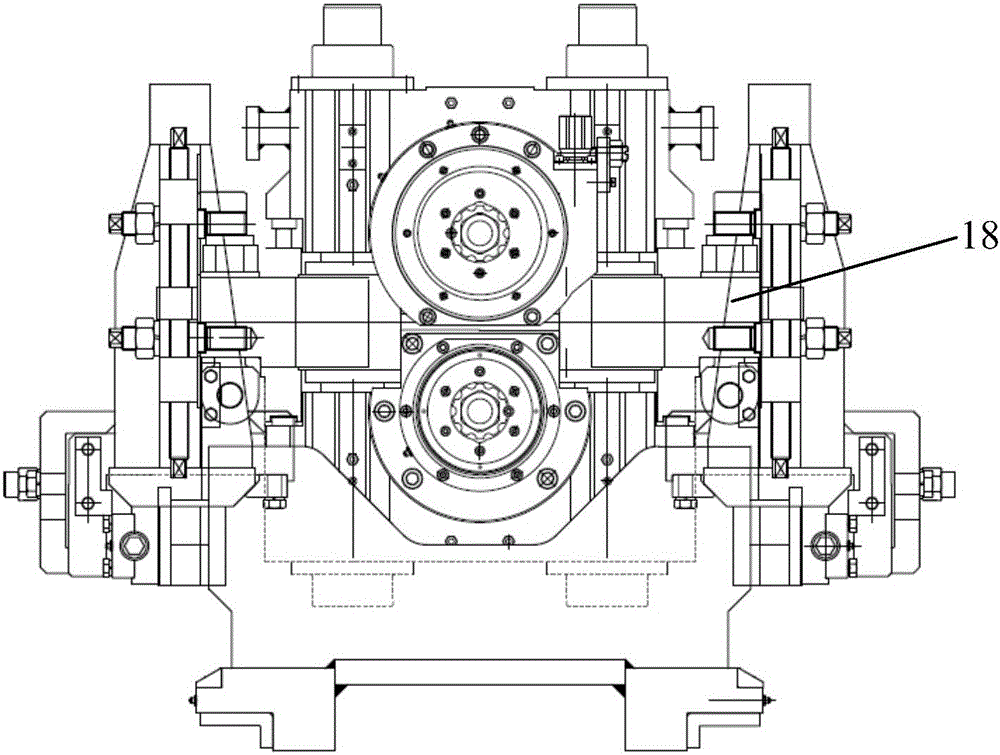

High-precision bar rolling mill

ActiveCN106180204ACompact structureEasy to disassembleMetal rolling stand detailsMetal rolling arrangementsSocial benefitsAxial displacement

The invention provides a high-precision bar rolling mill. The high-precision bar rolling mill comprises a base and a roller system. The roller system and the base are mounted and fixed through a roller system support. A conical hole and four grooves are formed in each stand column of the base of the rolling mill. Adjusting liner plates are arranged in the grooves. Vertical boss structures matched with the four grooves in each stand column of the base of the rolling mill are arranged on the four sides of the roller system support. An assembly gap between the roller system support and the stand columns of the base can be adjusted by tightly pressing screws through the adjusting liner plates. Semi-conical holes are formed in the middles of bosses of the roller system support and matched with the conical holes in the stand columns of the base of the rolling mill. The roller system support and the base of the rolling mill are locked through conical drift bolts. The high-precision bar rolling mill is compact in structure, easy to dismount and mount, high in rigidity, small in bounce value and free of axial displacement; round bar products rolled through the high-precision bar rolling mill are high in section size precision, small in ovality and especially suitable for production of bars; and domestication and batch manufacturing of the high-precision bar rolling mill can completely replace an import mode, and great economic and social benefits are achieved.

Owner:JIANGSU XIHU SPECIAL STEEL

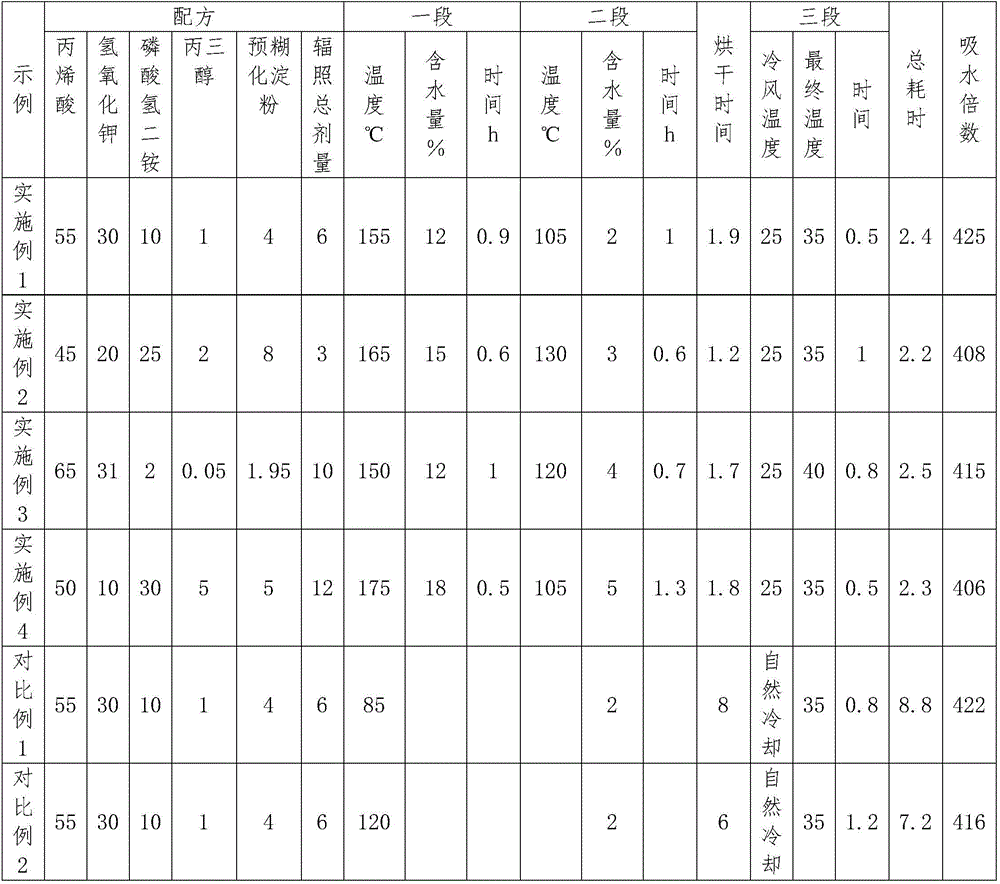

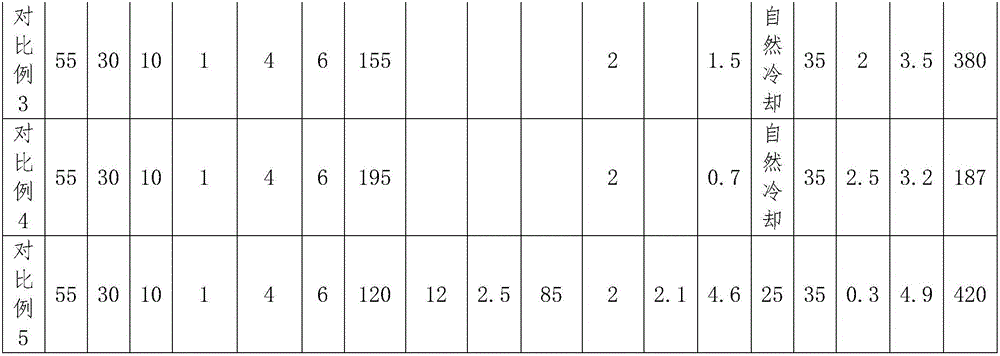

Method for preparing environment-friendly and multi-functional agro-forestry super absorbent polymer

ActiveCN106084132ANo residueNo pollution in the processOrganic fertilisersSoil conditioning compositionsEnvironmental resistanceCross-link

The invention discloses a method for preparing an environment-friendly and multi-functional agro-forestry super absorbent polymer, belonging to the field of preparation of agro-forestry superabsorbent polymers. The method sequentially comprises the following steps: (1) carrying out a neutral reaction, namely adding water into pregelatinized starch and stirring for 15-30 minutes to prepare gelatinized liquid, slowly adding potassium hydroxide and diammonium hydrogen phosphate, or ammonia water and dipotassium phosphate, or diammonium hydrogen phosphate and dipotassium phosphate for dissolving, slowly adding acrylic acid for neutralizing, and finally adding a cross-linking agent for uniformly mixing; (2) performing irradiation polymerization, namely separately packaging the neutralization solution into a polymerization container, and performing irradiation polymerization in an irradiation chamber, wherein the total irradiation dose is 3-15kGy; (3) drying, namely mincing gel blocks, and drying; and (4) crushing, namely crushing in a crusher, screening, thereby obtaining the agro-forestry absorbent polymer. The method disclosed by the invention is a method for preparing an energy-saving and environment-friendlyagro-forestry super absorbent polymer, and the prepared agro-forestry superabsorbent polymer has effects of preserving moisture and fertility, supplying plant nutrition and promoting growth.

Owner:SAAS BIOTECH & NUCLEAR TECH RES INST

Glass fiber grid cloth production device

The invention relates to a glass fiber grid cloth production device. The glass fiber grid cloth production device is characterized by comprising an unwinding roller set, a tension adjusting roller set, a primer pool, a drying tower mechanism, an adhesive sticker pool, a label pressing mechanism and a winding roller. Glass fiber grid cloth which is discharged from the unwinding roller set is discharged from an output end of the tension adjusting roller set, and then passes through a pressing roller of the primer pool to be stained with a primer; the glass fiber grid cloth which is output from the primer pool passes through a first lower reversing roller set firstly, upwards winds around a first upper reversing roller along the inner wall of a drying box, then downwards passes through a first lower reversing roller set to be output from the drying box, then is wound around a brush roller of the adhesive sticker pool, then enters a second lower reversing roller set in the drying box, thenupwards winds around a second upper reversing roller along the inner wall of the drying box, then downwards passes through a second lower reversing roller set to be output, then is stored and air-dried through a cloth storage frame after undergoing label pressing through the label pressing mechanism, and finally is wound around the winding roller. The whole production device is simple in structure, reasonable in design and suitable for mass production and use.

Owner:南通拓普新型建材有限公司

Recycled fine aggregate high-strength self-compacting concrete

The invention discloses recycled fine aggregate high-strength self-compacting concrete, which is prepared from the following raw materials in parts by weight: 180 to 200 parts of cement, 350 to 400 parts of stone, 250 to 300 parts of coarse aggregate, 190 to 220 parts of recycled fine aggregate, 40 to 60 parts of steel slag, 50 to 70 parts of fly ash, 15 to 20 parts of filler, 30 to 50 parts of modified zeolite powder, 5 to 10 parts of water reducing agent and 100 to 120 parts of water. By using the recycled fine aggregate, the use amount of natural fine aggregate such as river sand is reduced, the cost is saved, the resource loss is reduced, the modified zeolite powder reacts with cement to generate calcium silicate hydrate, cement hydration is promoted, the viscosity is improved, the use amount of the cement can be remarkably reduced, the hardness of the zeolite powder is obviously greater than that of the cement, the hardness of the concrete material is obviously improved, the strength of the cement is further improved, the cost performance is excellent by adding the steel slag, and the cement is suitable for production and use.

Owner:南通市国石商品混凝土有限公司

Circumferential automatic welding device

InactiveCN103785927BEasy to installLower requirementWelding/cutting auxillary devicesElectrode holder supportersDrive shaftPulley

The invention discloses an automatic circumference welding device, and relates to the technical field of welding equipment. The automatic circumference welding device comprises a machine frame. A motor is installed inside the machine frame, and the output end of the motor is connected with a main belt pulley which is respectively connected with a first belt pulley and a second belt pulley through belts. The first belt pulley is connected with a first welding and clamping mechanism through a gear in a transmission mode, and drives the first welding and clamping mechanism to do circumferential movement. One side of the first welding and clamping mechanism is located on the machine frame and provided with a first welding gun clamping mechanism. The second belt pulley is connected with a transmission shaft in a transmission mode. The end of the transmission shaft is connected with a second welding and clamping mechanism, the second belt pulley drives the second welding and clamping mechanism to do circumferential movement, and one side of the second welding and clamping mechanism is located on the machine frame and connected with a second welding gun clamping mechanism. The automatic circumference welding device is simple in structural design and very convenient to operate, the requirement for operation workers is not high, components are installed conveniently, the welding requirements of various circular or arc components can be met by replacing different clamps, and the automatic circumference welding device is wide in application range.

Owner:JINZHAI COUNTY WEIMING MACHINERY MFG

Cabbage cut browning inhibitor and use method thereof

ActiveCN104621244AInhibition of incision browningExtended shelf lifeFruit and vegetables preservationAcetic acidSURFACTANT BLEND

The invention belongs to the field of agricultural preservation technology, particularly to a cabbage cut browning inhibitor and a use method thereof. The browning inhibitor is a peracetic acid composition which comprises the following ingredients by mass percent: 0.3-20.0% of peracetic acid, 0.3-20.0% of hydrogen peroxide, 0.5-30.0% of acetic acid, 0.5-20.0% of a wetting agent and 0.5-30.0% of a surfactant. The present invention also relates to a use method of the browning inhibitor. The method is as follows: after harvest, stripping outer leaves and cutting partial stem from cabbage, dipping, wiping or spraying the browning inhibitor on the cabbage cut, and then conducting packaging, distribution or marketing. The browning inhibitor can extend shelf life of cabbage in distribution process for more than two days, and the method has characteristics of high security, ease of operation and promotion, suitability for production use and low cost.

Owner:山东麦格纳材科技有限公司

Mangosteen skinning device

InactiveCN107856147ACompact structureSuitable for production useCane mechanical workingEngineeringDrive motor

Owner:沈玉云

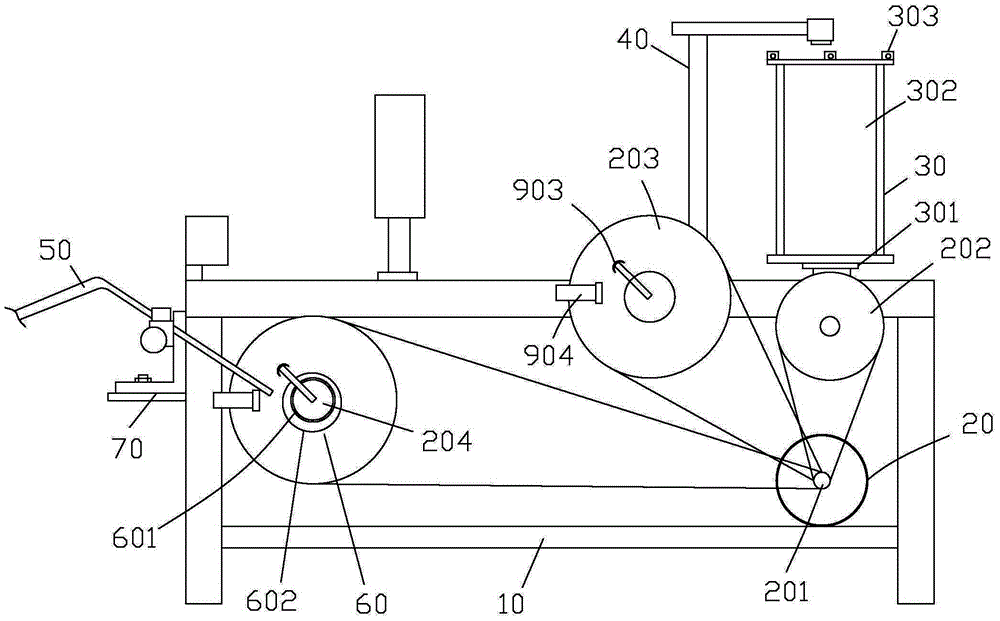

Production system of instant starch noodles

InactiveCN107772429ASuitable for production useIncrease productionFood scienceContinuous/uninterruptedWater baths

The invention discloses a production system of instant starch noodles. The production system comprises a dough mixing machine for mixing raw materials, a starch noodle molding machine for molding thestarch noodles, a pre-freezer for cooling the starch noodles, a freezer for ageing the starch noodles, a cutting machine for cutting the starch noodles into sections and a packaging machine; a boilingpot and a heating device for heating the boiling pot are arranged below the starch noodle molding machine; a cold water groove is formed behind the boiling pot; the cold water groove is obliquely formed with a high front and a low back; a cooling water spraying nozzle is arranged at the rear end of the cold water groove; the cooling water spraying nozzle is used for spraying from bottom to top along an extending direction of the cold water groove. The production system of the instant starch noodles, which has the structure, is used for producing the starch noodles in a large scale. The production system of the instant starch noodles can be used for carrying out continuous working, has a large yield and less manual intervention and is suitable for production of enterprises.

Owner:重庆市黄海食品有限公司

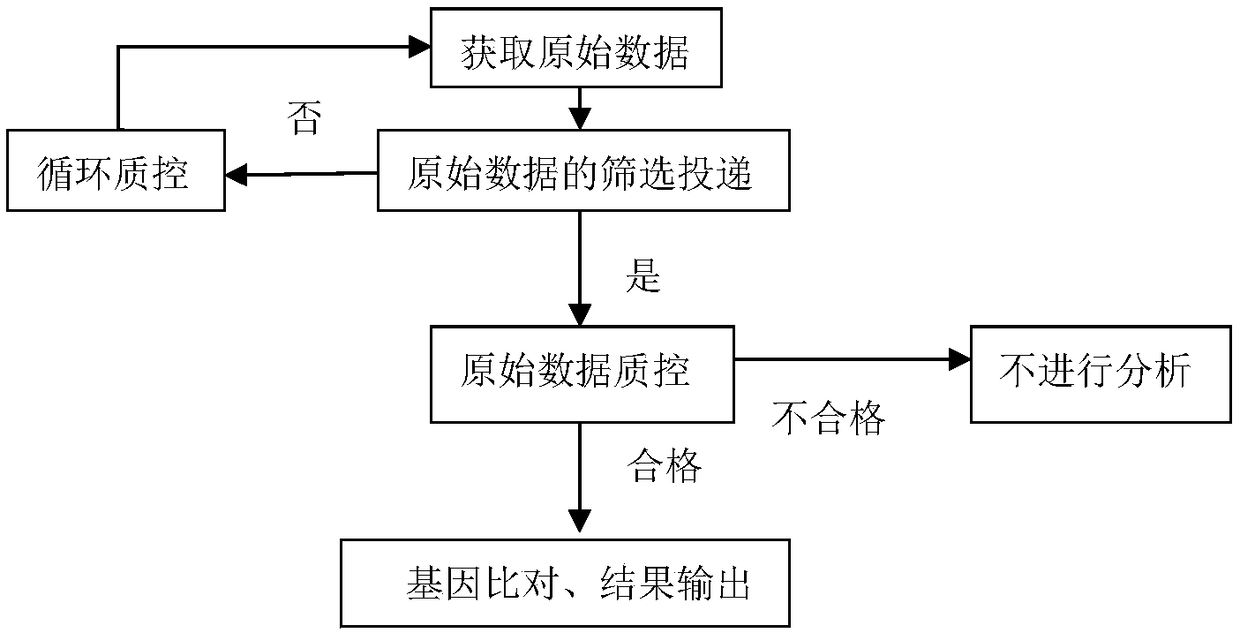

Noninvasive prenatal bioinformatics detection system and method as well as application

InactiveCN108388770AReduce complexityReduce mistakesSequence analysisHybridisationAutoanalysisOriginal data

The invention discloses a noninvasive prenatal bioinformatics detection system and method as well as application. The method comprises the following steps: 1) extracting cfDNA of peripheral blood of apregnant woman, and performing whole genome sequencing to obtain original offline data; 2) monitoring the original offline data by an automatic monitoring program, and automatically completing the delivery task of an analysis process; and 3) automatically completing the splitting task of the offline data, the quality control of fastq original data as well as the comparison and quality control ofreference genomes. The method disclosed by the invention can automatically complete the whole processes of data offline monitoring, automatic analysis and acquisition of detection results, and does not need personnel for operating so as to reduce the errors caused by human factors and reduce the complexity of data analysis, so that the method is more suitable for being put into production.

Owner:北京爱普益医学检验中心有限公司

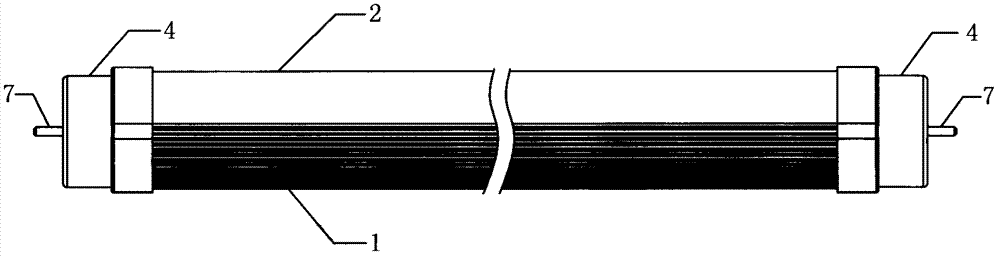

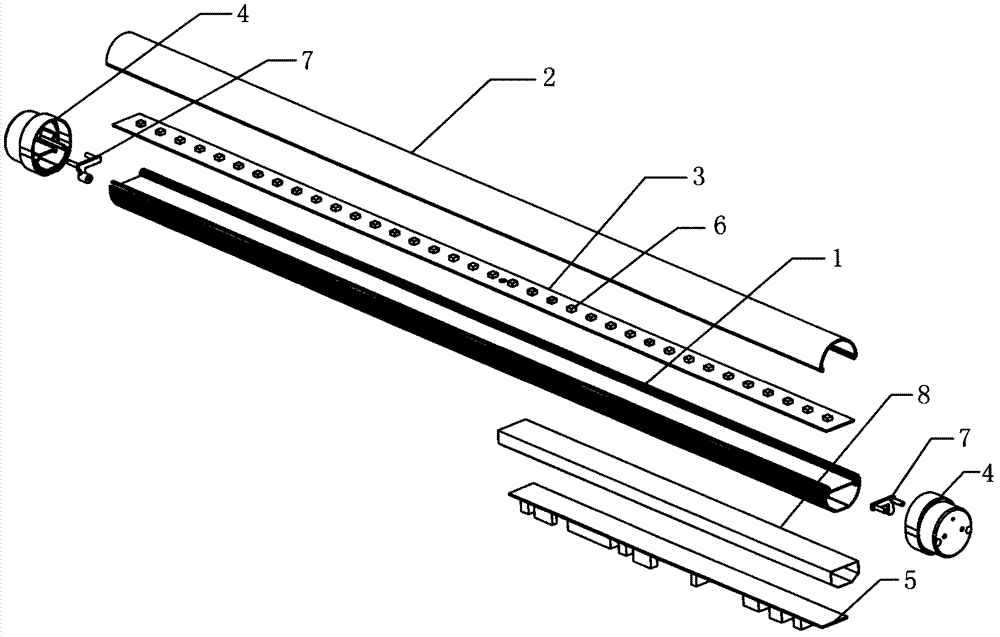

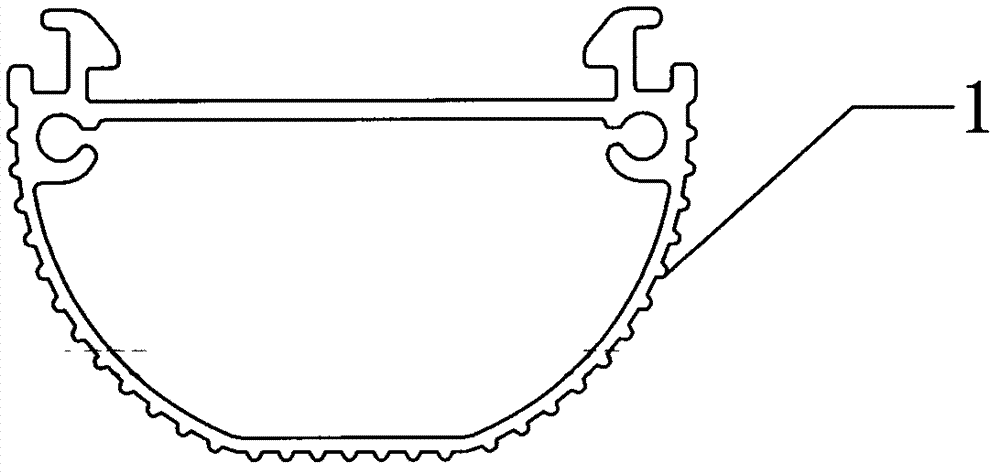

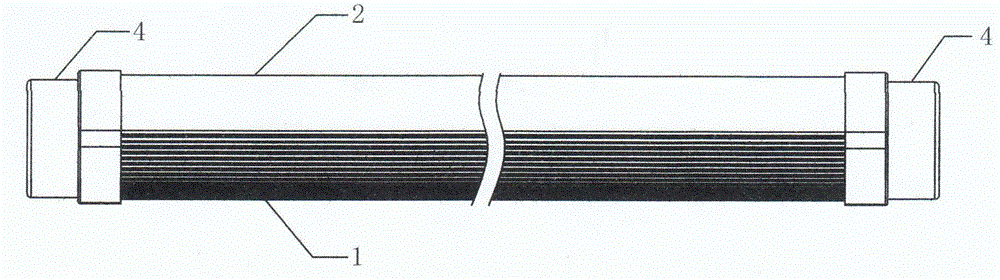

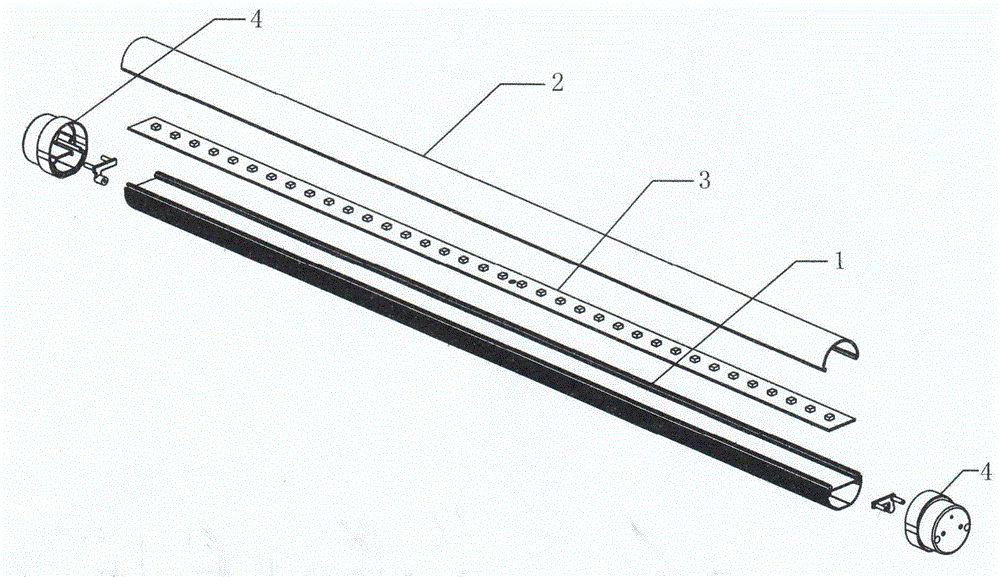

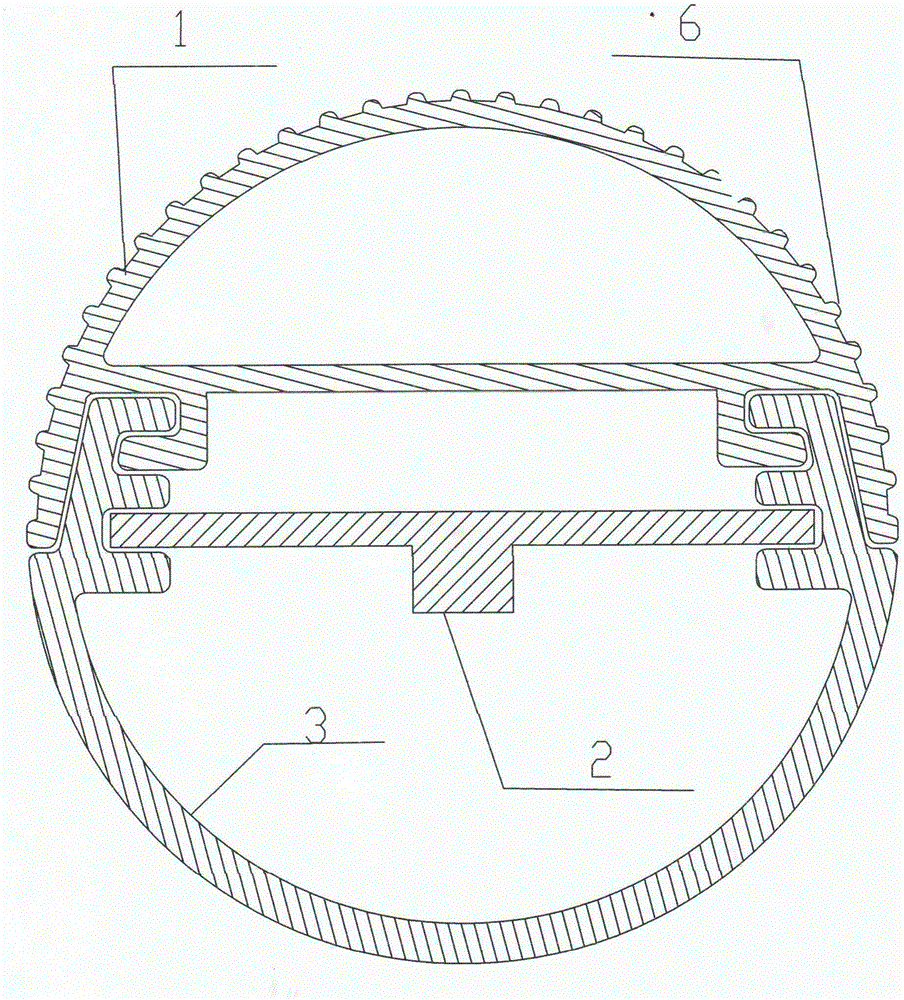

Light-emitting diode (LED) fluorescent lamp free from glare

InactiveCN102788263ABig spaceNot easy to short circuitPoint-like light sourceElectric circuit arrangementsPublic placeEngineering

The invention discloses a light-emitting diode (LED) fluorescent lamp free from glare. The LED fluorescent lamp comprises a bottom groove 1, a lamp shade 2 and a light source plate 3 arranged in the lamp shade, wherein the bottom groove 1 and the lamp shade 2 are fixedly connected to form a lamp body, lamp holders 4 are connected with two ends of the bottom groove 1, a drive power supply 5 is arranged in the bottom groove 1, a plurality of LEDs 6 are installed on the light source plate 3, bronze needles 7 are arranged on the lamp holders 4 in an injection molding mode, and an insulating sleeve 8 is coated on the exterior of the drive power supply 5. The LED fluorescent lamp free from the glare has the advantages of being difficult to result in short circuit of the drive power supply, wide in luminescence irradiation range, simple in structure, low in cost and durable, and besides, the LED fluorescent lamp is capable of being widely used in various public places and applicable to mass production and usage.

Owner:GUANGDONG TONGFANG LIGHTING

Method for producing concentrated inactivate vaccine for newcastle disease

ActiveCN101474401BGood concentration and stabilityHigh potencyViral antigen ingredientsAntiviralsAnti virusAntigen

Owner:RINGPU (BAODING) BIOLOGICAL PHARMACEUTICAL CO LTD

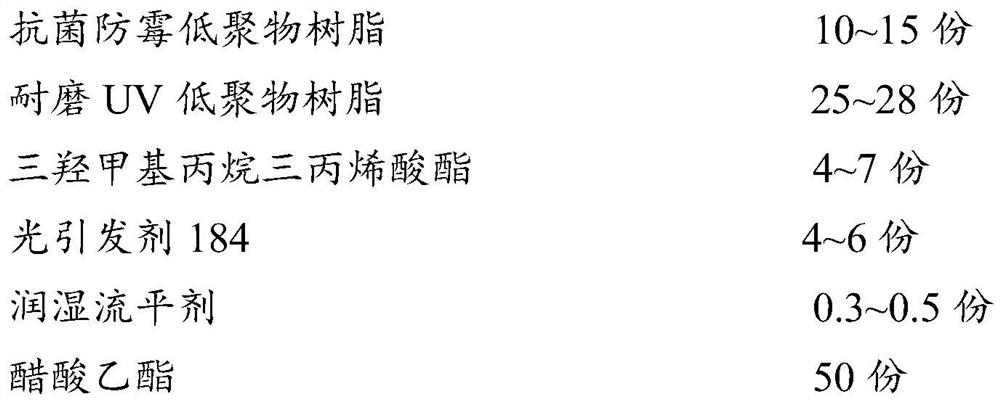

Glass explosion-proof film with antibacterial and mildew-proof effects and preparation method thereof

ActiveCN111892883ANo leachingLong-lasting antibacterial and antifungal effectAntifouling/underwater paintsFilm/foil adhesivesMethacrylateDiacetonamine

The invention relates to a glass explosion-proof film with antibacterial and mildew-proof effects. The glass explosion-proof film comprises a PET protective film, a UV photocuring coating, a PET pre-coating film, a mildew-proof resin mounting adhesive layer and a PET release film from outside to inside, wherein the UV photocuring coating is prepared from the following main raw materials by mass: 10-15 parts of antibacterial mildew-proof oligomer resin, 25-28 parts of wear-resistant UV oligomer resin, 4-7 parts of trimethylolpropane triacrylate, 4-6 parts of a photoinitiator 184, 0.3-0.5 part of a wetting leveling agent and 50 parts of ethyl acetate; the mildew-proof resin mounting adhesive layer is prepared from the following main raw materials by mass: 10-20 parts of PHMG-PUA, 10-15 partsof butyl acrylate, 8-14 parts of isooctyl methacrylate, 5-10 parts of diacetone acrylamide, 3-5 parts of azodiisobutyronitrile and 50 parts of ethyl acetate. Compared with the prior art, the preparedexplosion-proof film has lasting antibacterial and mildew-proof effects, the effective rate of inhibiting and killing Gram-negative escherichia coli and Gram-positive staphylococcus aureus reaches 96% or above, and meanwhile, the invention further provides a preparation method of the glass explosion-proof film with the antibacterial and mildew-proof effects.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

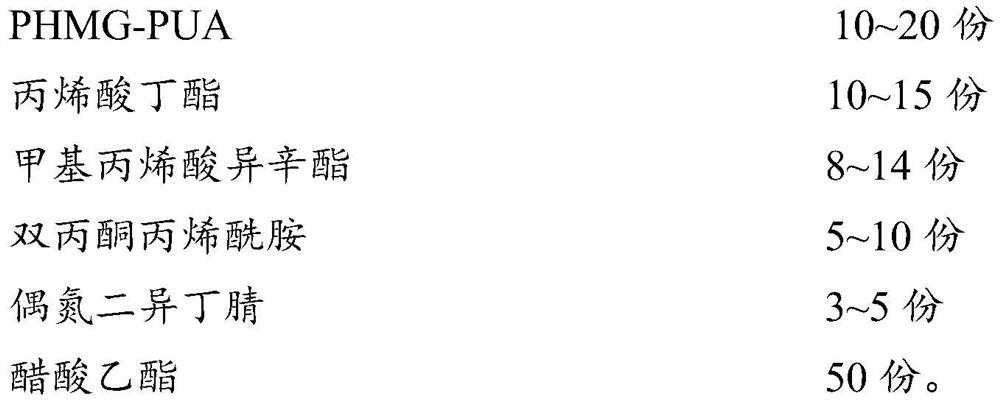

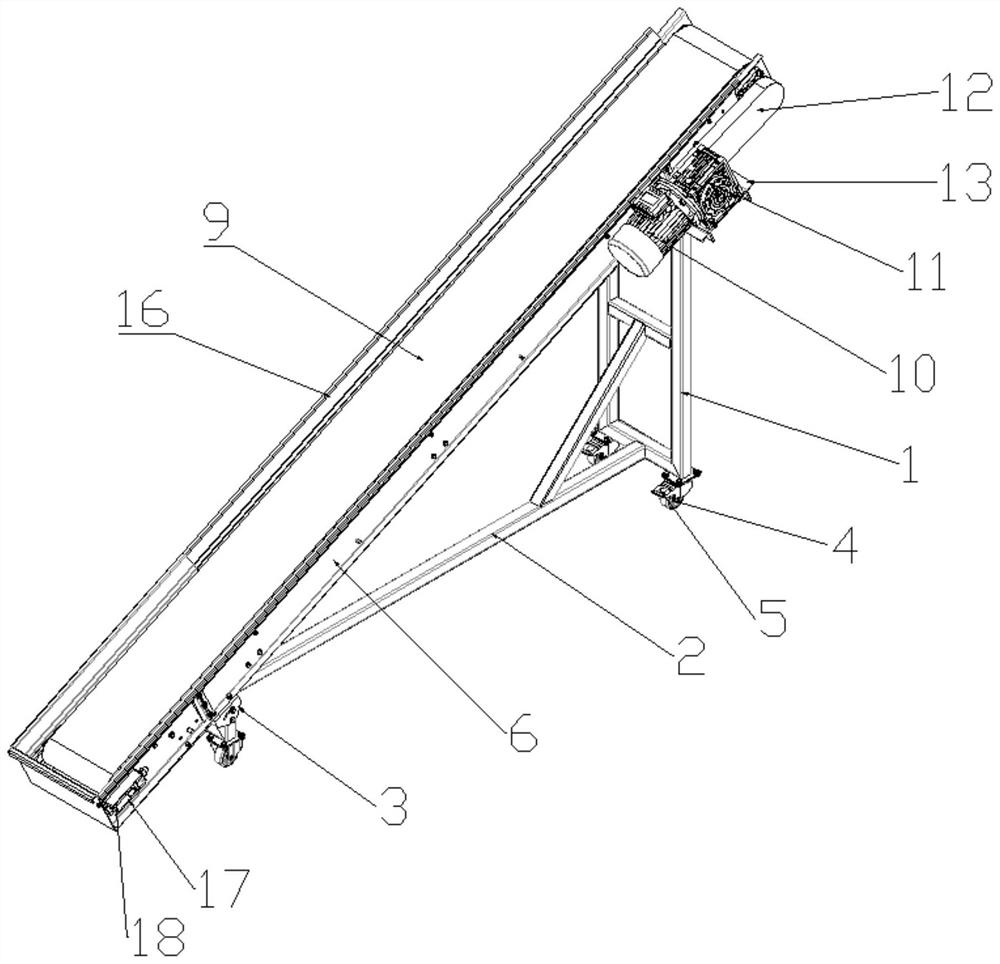

Inclined conveying belt conveyor

The invention provides an inclined conveying belt conveyor which comprises a machine frame and a conveying mechanism obliquely installed on the machine frame. The machine frame comprises a bottom frame and vertical frames arranged at the two ends of the bottom frame. The upper ends of the vertical frames are fixedly connected with the conveying mechanism through fixing plates. Sliding wheels are arranged on the periphery of the bottom frame, and brake plates are arranged on the sliding wheels. The device moves through the sliding wheels and is fixed through foot brakes on the sliding wheels, the position is convenient to adjust, a driving mechanism drives a second conveying roller to rotate so as to drive a conveying belt to move, protection plates are arranged at the two ends of the frame, and transported materials are prevented from falling off. The device is simple in structure, convenient to operate and suitable for production and use within a small range.

Owner:淮南市松江电子有限责任公司

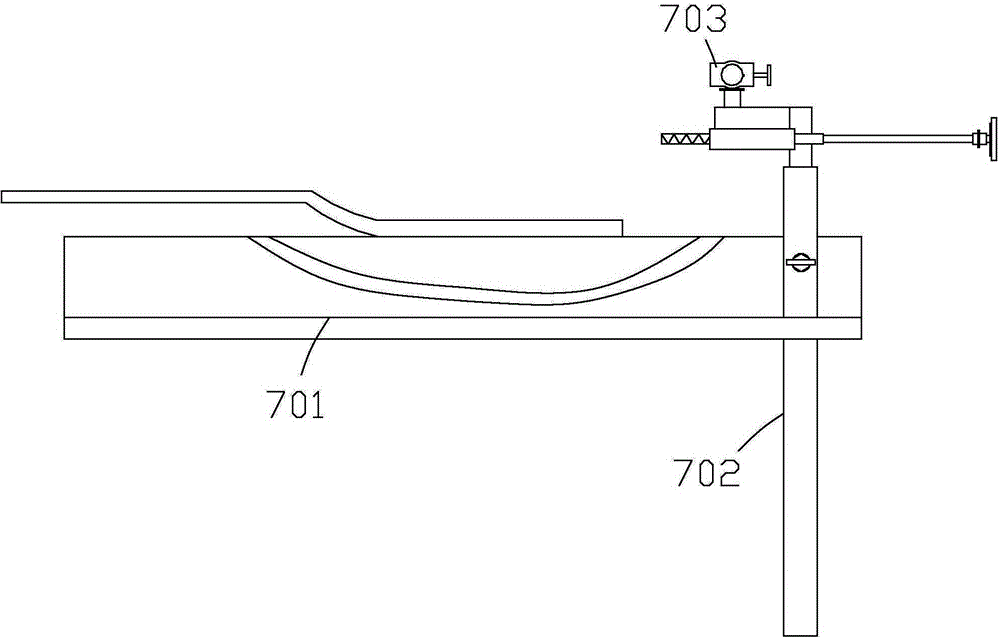

Dead weight type triaxial apparatus water injection and drainage device

InactiveCN109738292ARealize water injection functionEasy to pull upMaterial strength using tensile/compressive forcesEngineeringMechanical engineering

The invention discloses a dead weight type triaxial apparatus water injection and drainage device, comprising a container, a telescopic rod, a water tank, a pressing plate I, a pressing plate II and asealing component; the telescopic rod is mounted in the container; the container is communicated with the water tank by virtue of a water inlet pipe, a water injection pipe is arranged at the bottomof the container; the pressing plate I sheathes the telescopic rod; the pressing plate II movably sheathes the telescopic rod and is located above the pressing plate I; the sealing component is arranged between the pressing plate I and the pressing plate II; the diameters of the pressing plate I and the pressing plate II are smaller than the diameter of the container, and the end parts of the pressing plate I and the pressing plate II are wrapped and surrounded by an annular sealing ring; and the sealing component comprises a spring, a sheath ring, a connecting rod and a supporting rod. The dead weight type triaxial apparatus water injection and drainage device disclosed by the invention controls water injection and water drainage operations of a pressure chamber in a triaxial apparatus ina manual manner, water injection process can be controlled more conveniently, and structure design of a composition device is relatively ingenious, so that cost is lower, and the device disclosed bythe invention is more applicable to being put into production in commission.

Owner:ZHEJIANG IND POLYTECHNIC COLLEGE

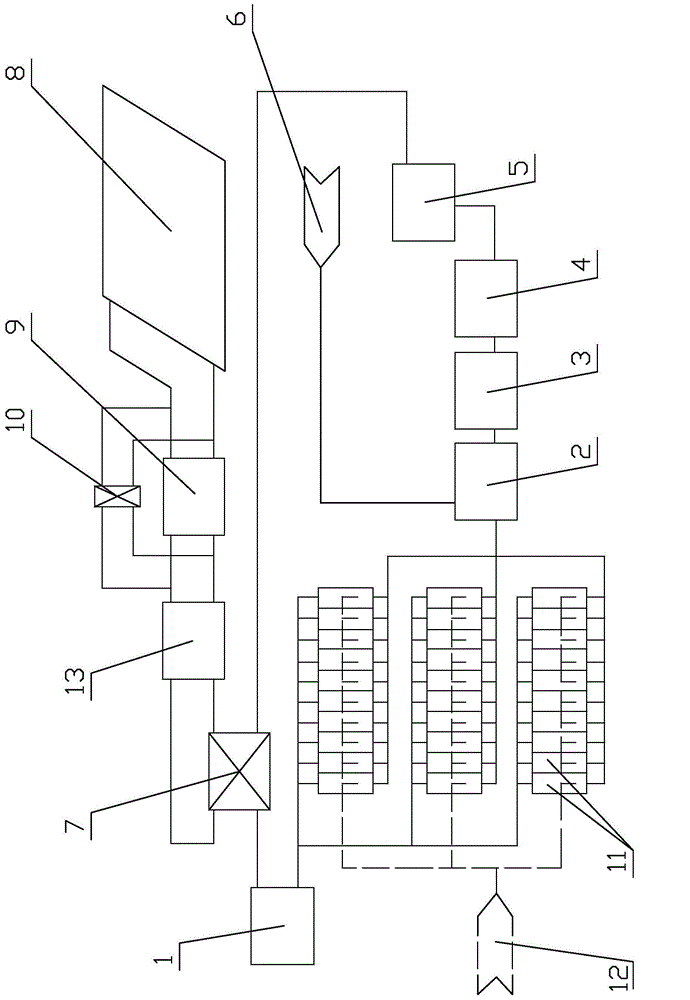

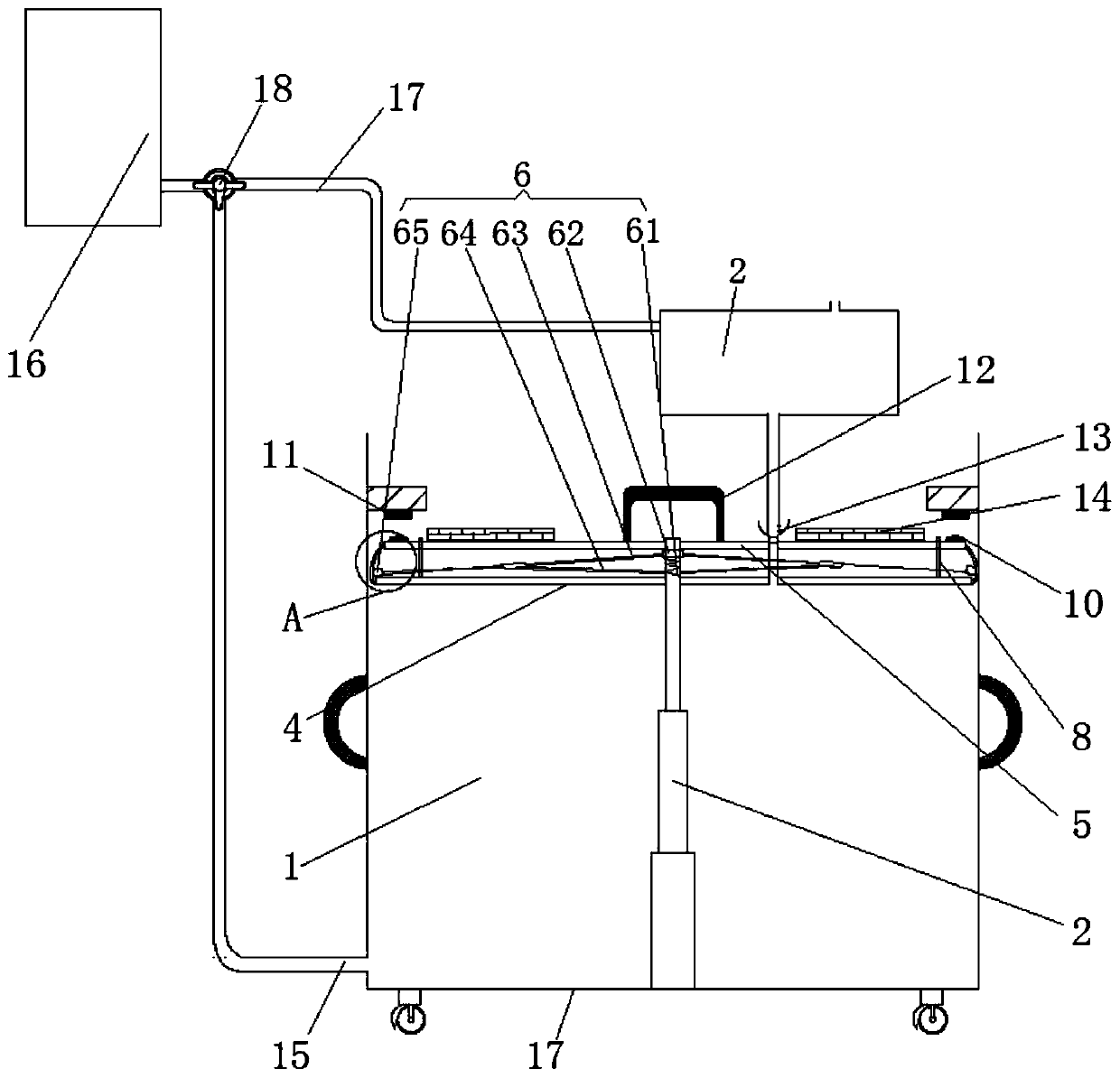

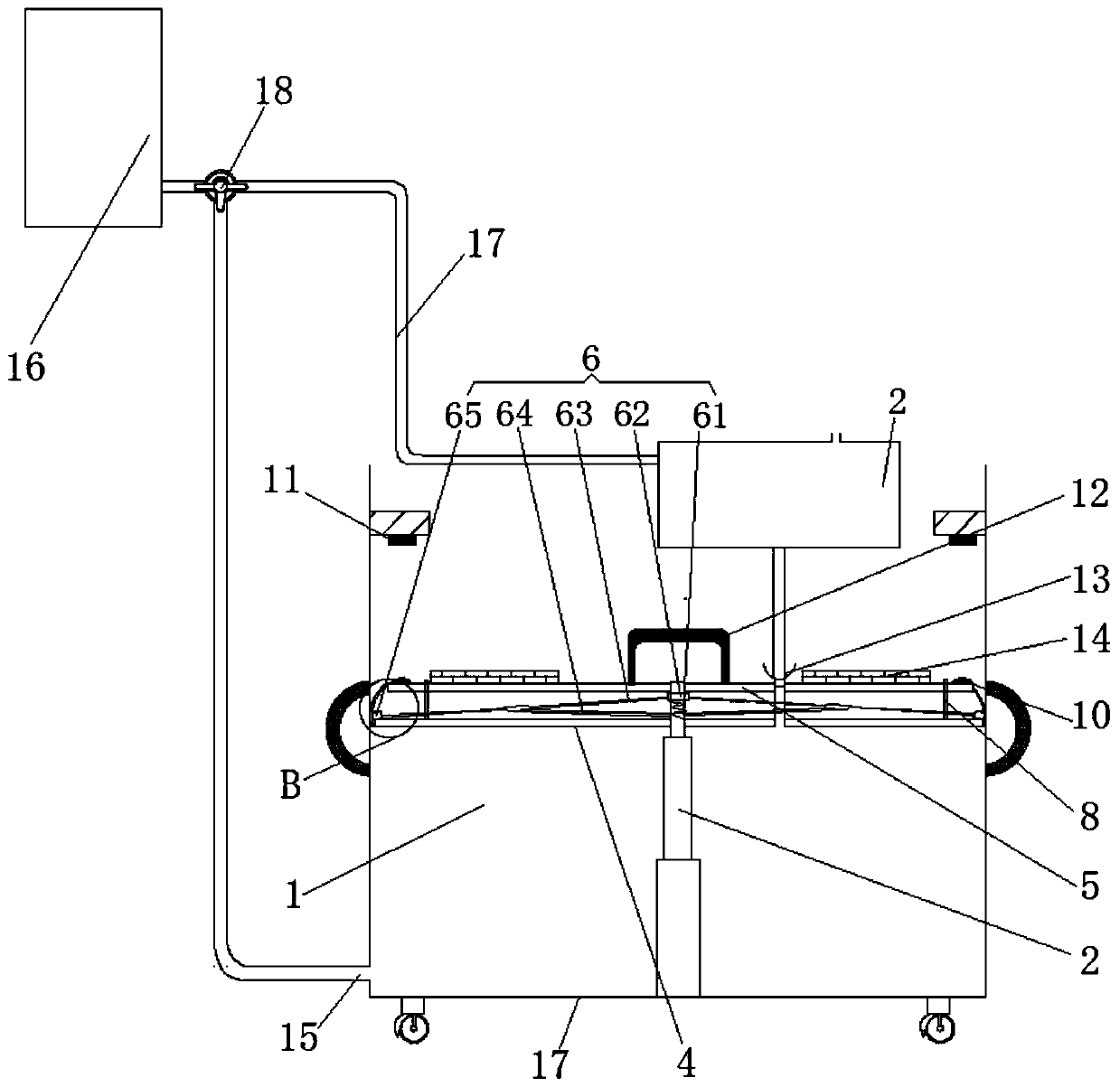

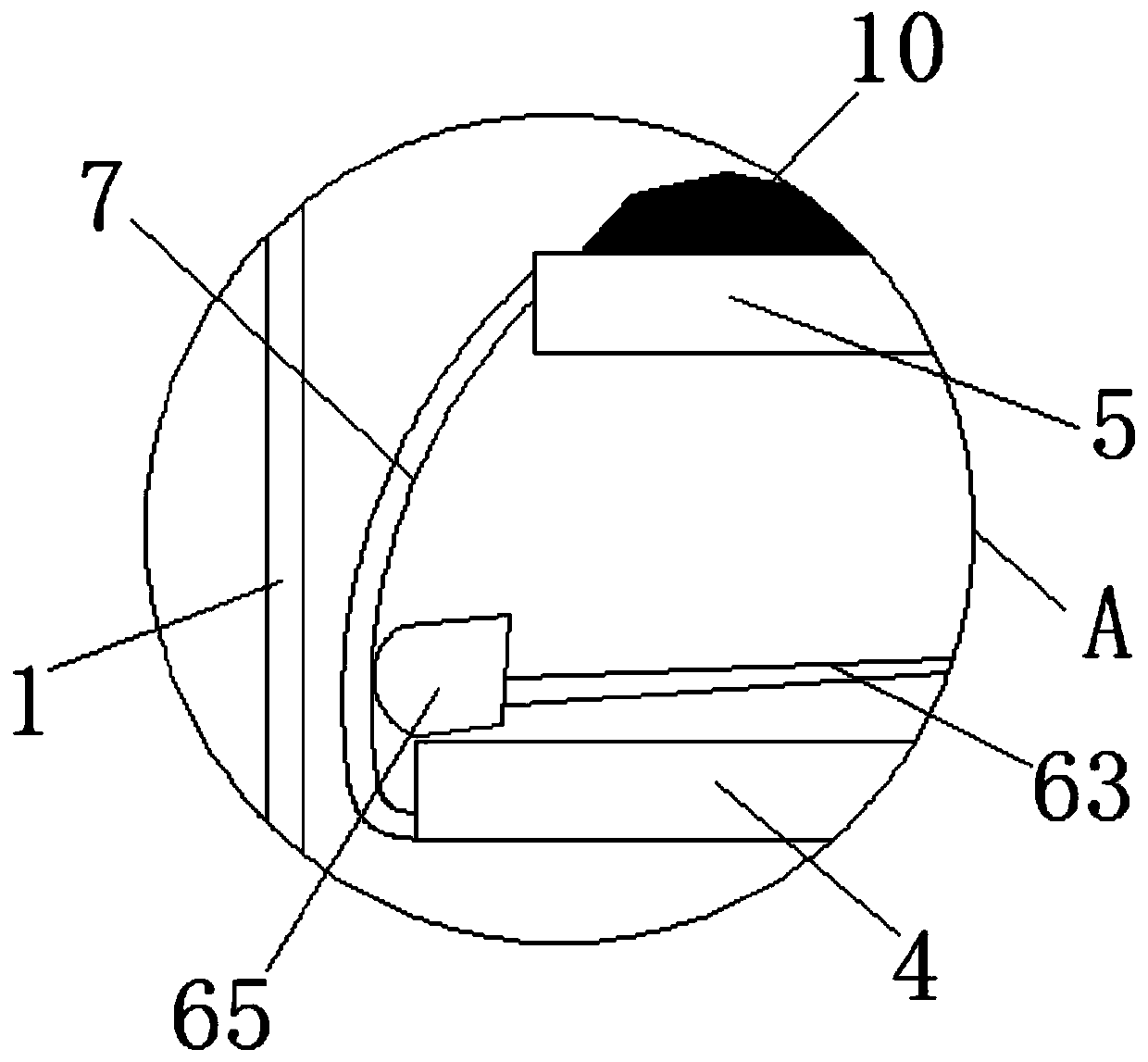

Refractory gasified slag flotation separation method based on residual carbon particle pore filling

ActiveCN113351363AReduce adverse effectsEnhanced flotation processSolid waste managementFlotationFoaming agentSlag

The invention relates to the technical field of gasified slag flotation, in particular to a refractory gasified slag flotation separation method based on residual carbon particle pore filling. The refractory gasified slag flotation separation method based on residual carbon particle pore filling is characterized in that gasified slag and a certain amount of carbon-containing superfine hydrophobic particles are mixed and then added into a ball mill for ore grinding, then the mixture is put into a flotation machine, then a high-temperature vaporized foaming agent is utilized, air is used for carrying the vaporized foaming agent to enter the flotation machine, flotation is completed together with a collecting agent, and finally flotation concentrate and tailings are collected. According to the refractory gasified slag flotation separation method based on residual carbon particle pore filling, the carbon-containing superfine hydrophobic particles are embedded into pores of the gasified slag in the ore grinding stage, treatment is combined with the vaporizing foaming agent, waste caused by the fact that the foaming agent enters the pores can be reduced, and therefore the whole flotation process of the gasified slag can be efficiently carried out.

Owner:CHINA UNIV OF MINING & TECH

Novel glare-free LED lamp

InactiveCN104976529AWide range of luminescenceSimple structurePoint-like light sourceElongate light sourcesEngineeringIrradiation

The invention discloses a novel glare-free LED lamp. The novel glare-free LED lamp comprises a bottom groove, a lampshade and a light source panel arranged in the lampshade. The bottom groove and the lampshade are fixedly connected to form a lamp body. Lamp bases are connected to the two ends of the bottom groove. A plurality of LEDs are mounted on the light source panel. The novel glare-free LED lamp is wider in light-emitting range and irradiation range and has the advantages of being simple in structure, low in cost and durable, and the novel glare-free LED lamp can be widely used in various pubic places and suitable for mass production and application.

Owner:郑华耀

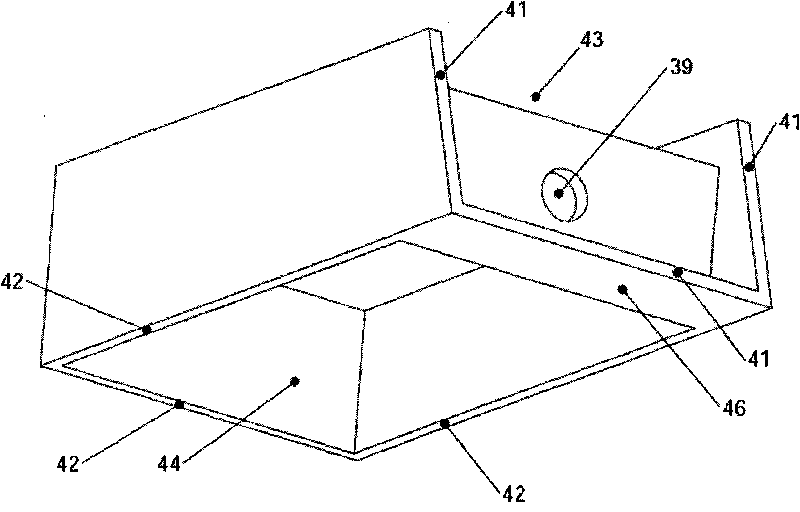

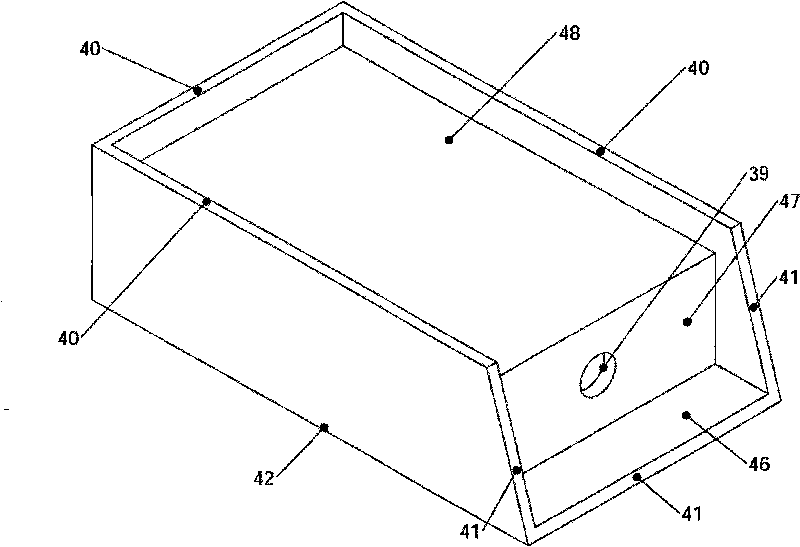

Automobile engine cylinder head with complex shape and device for detecting flaws and leakage of tightness of automobile engine cylinder head with complex shape

ActiveCN101696662AReliable leak detectionImprove efficiencyCylinder headsCylindersAssembly lineFully automatic

The invention discloses an automobile engine cylinder head with a complex shape and a device for detecting flaws and leakage of tightness of the automobile engine cylinder head with the complex shape, belongs to the technical field of industrial part processing and detection, particularly relates to a technique for detecting defects and leakage of complex automobile engine cylinder heads. The invention is characterized in that: the automobile engine cylinder head is of a dustpan shape, and has complex shape of having three edge planes; the leakage detection device is a plugging device formed by covering a panel controlled by an air cylinder or an oil cylinder and sealing planes of different edges; the different plugging devices comprise a top plugging device, a side-inclined plane plugging device, a bottom plugging device, and an interlayer through hole plugging device. The device has the advantages that: the device can perform plugging, flaw and leakage detection on the similar dustpan-shaped open cylinder head, complete the plugging and flaw detection of the interlayer holes, can be used on the entire fully-automatic assembly line because of being equipped with an automatic in-place feeding and discharging device, achieves the aims of reliable detection and high efficiency, and is suitable to be used in production.

Owner:SHANGHAI MINGXING KAICHENG ULTRASONIC TECH

LED illuminating lamp dimming device and LED lamp with same

InactiveCN106609927AWide range of luminescenceSimple structureElongate light sourcesGlobesPublic placeEngineering

The invention discloses an LED illuminating lamp dimming device and an LED lamp with the same. The LED lamp comprises a bottom groove, a lamp cover and a light source plate arranged inside the lamp cover. The bottom groove and the lamp cover are fixedly connected to form a lamp body. The two ends of the bottom groove are connected with lamp holders. A plurality of LEDs are installed on the light source plate. The light radiating range of the LED lamp is made wider. Moreover, the LED lamp has the advantages of being simple in structure, low in cost, durable in use, capable of being widely applied to various public places and suitable for mass production and use.

Owner:郑华耀

Pretreatment method and treating machine for hogwash refuse of kitchen

InactiveCN100496777CReduce transport volumeAvoid pollutionSolid waste disposalElectricityPretreatment method

The invention relates to a pretreatment of kitchen garbage waste, and relative processor, wherein it is characterized in that: said method separates the solid and liquid matters, which uses breaking, compressing, removing liquid removing oil, and dewatering; the oil is collected into oil collect tank; the non-oil liquid is fed into the life sewage tube network; the compressed solid garbage is fed into the slag storage tank to be stored in solid carrier; the oil is carried via storage carrier. The invention comprises two meshed rolling tooth wheels, whose meshed center is under the feeding groove and under the broken guide groove; and it comprises a compress baffle plate, an oil-water separator and an oil collecting tank. The invention has small volume, less electricity consumption and simple operation.

Owner:钟建成

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com