Production process of multi-layer pulp washing net

A production process and pulp washing technology, applied in the direction of multi-strand fabrics, fabrics, open-hole fabrics, etc., can solve the problems that the service life cannot meet the requirements of use, the loss of pulp, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

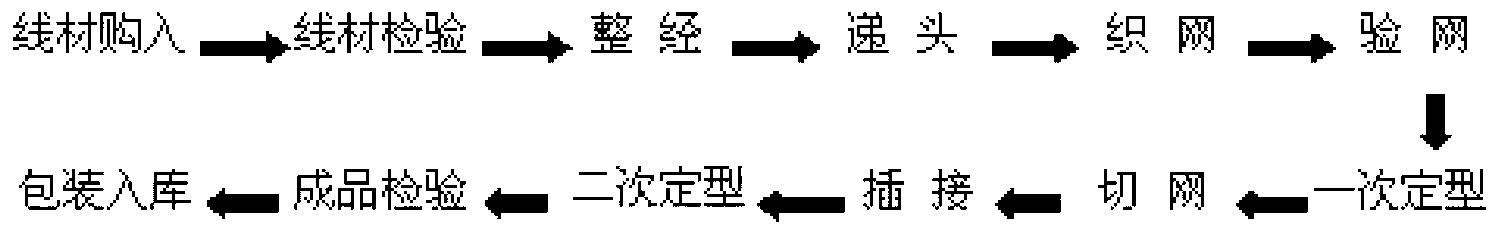

[0039] A production process for a multi-layer pulp washing net, comprising the following steps:

[0040] (1) Wire purchase

[0041] According to the requirements of the production plan, import high-quality monofilament from Germany according to the model, quality and quantity;

[0042] (2) Wire inspection

[0043] According to the requirements of the production plan, the wire diameter, heat shrinkage, tensile strength, acid and alkali resistance and other indicators are inspected one by one. According to the specific production requirements, random inspections and full inspections are carried out in batches.

[0044] Warp: Ф0.45mm, tensile strength: 900N / mm 2 , heat shrinkage value: 14%;

[0045] Weft 1: Ф0.30mm, tensile strength: 600N / mm 2 , heat shrinkage value: 2%;

[0046] Weft 2: Φ0.25mm, tensile strength: 650N / mm 2 , heat shrinkage value: 10%;

[0047] Weft 3: Φ0.50mm, tensile strength: 500N / mm 2 , heat shrinkage value: 9%;

[0048] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com