Refractory gasified slag flotation separation method based on residual carbon particle pore filling

A technology of pore filling and gasification slag, which is applied in flotation, solid separation, etc., can solve the problems of large voids, gasification slag with many pores, and cannot be well adapted to the problem of gasification slag flotation and separation, and achieves low price , Strengthen the effect of the flotation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

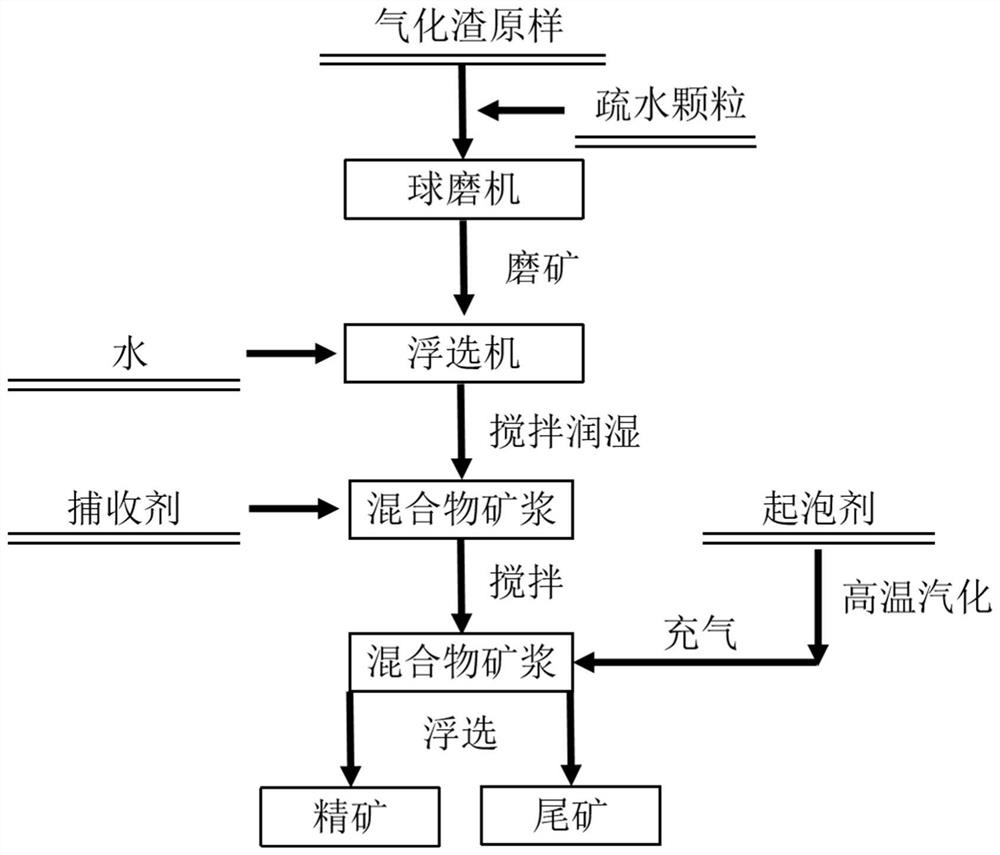

[0031] Such as figure 1 As shown, a refractory gasification slag flotation separation method based on pore filling of carbon residue particles, the steps are as follows:

[0032] S1. Gasification slag pre-grinding, the average particle size of gasification slag after pre-grinding is less than 0.045mm; mix the gasification slag after pre-grinding with hydrophobic particles at a mass ratio of 100:1-6, and then add it to the ball mill , grinding for 15 minutes; the hydrophobic particles are ultrafine graphite, ultrafine clean coal and other particles with a carbon mass fraction higher than 95%, and the particle size of the hydrophobic particles is 1-2 μm;

[0033] S2. Put the product of S1 into the flotation machine, add water 15-40 times the product quality and stir evenly to form a slurry, so that the mineral particles are suspended in the water;

[0034] S3. Add a non-polar hydrocarbon oil collector to the flotation machine, and use an alcohol foaming agent to heat for 2-5 mi...

Embodiment 2

[0038] The gasification slag raw material with an ash content of 80-81% was used as the test material, and the following tests were carried out:

[0039] 1. The test group carries out gasification slag flotation separation with the method of the present invention, and the process is as follows:

[0040] S1. Mix 49g of the gasification slag sample after grinding with 1g of ultra-fine graphite particles evenly, put it into a ball mill, grind for 15min and collect the samples after grinding.

[0041] S2. After the ore grinding, the sample is added to a 1L mechanically stirred flotation machine in the laboratory, and water is added to open the flotation machine, the air inlet valve is closed, and stirred for 2 minutes.

[0042] S3. Add 0.15g of diesel oil to the above flotation machine as a collector, and at the same time, put 0.2g of methyl isobutyl carbinol as a foaming agent into a 50mL heater and heat at 120°C, and continue to stir for 3min ;

[0043] S4. Connect the air out...

Embodiment 3

[0052] Adopt the same material and method as embodiment 2, adjust the diesel oil in the collector to be kerosene, record the flotation contrast test result as shown in table 2 below:

[0053] Table 2 flotation comparison test results

[0054]

[0055] The result of data comparison shows that compared with the traditional method, the concentrate flotation yield of the present invention is increased by 15.43%, which proves that the flotation method provided by the present invention has a better effect.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com