Glass explosion-proof film with antibacterial and mildew-proof effects and preparation method thereof

An antibacterial, mildew proof and glass technology, applied in the direction of biocide-containing paint, antifouling/underwater paint, film/flake adhesive, etc. The scope of application, the limited bacteriostatic efficiency, etc., to achieve the effect of maintaining clear transparency, strong antibacterial and antifungal effects, and lasting antibacterial and antifungal effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

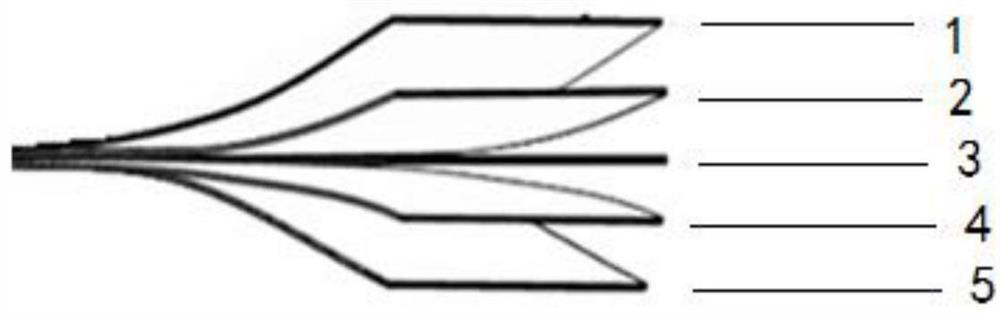

Image

Examples

preparation example Construction

[0047] The present invention also provides a method for preparing a glass explosion-proof film with antibacterial and antifungal effects, comprising the following steps:

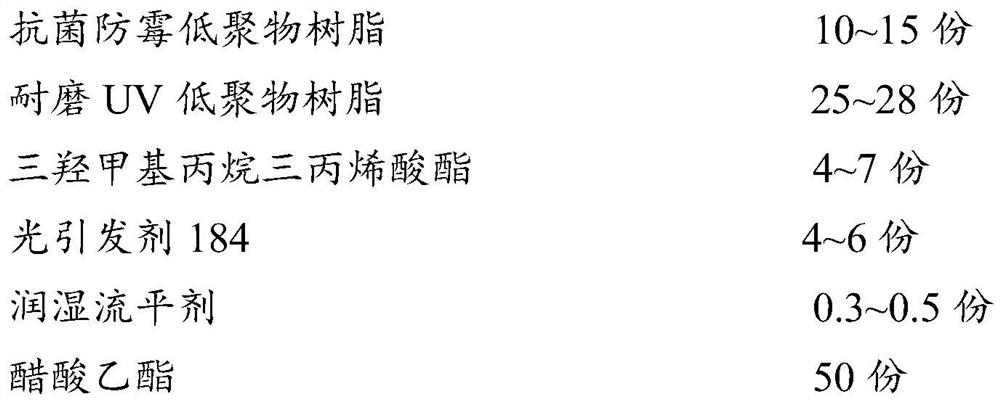

[0048] (1) Preparation of UV photocurable coating composition:

[0049] According to the mass ratio mentioned above, take antibacterial and mildew-proof oligomer resin, wear-resistant UV oligomer resin, trimethylolpropane triacrylate, photoinitiator 184, wetting and leveling agent, ethyl acetate, in Disperse and stir evenly in a light-proof container to obtain a UV light-curable coating composition.

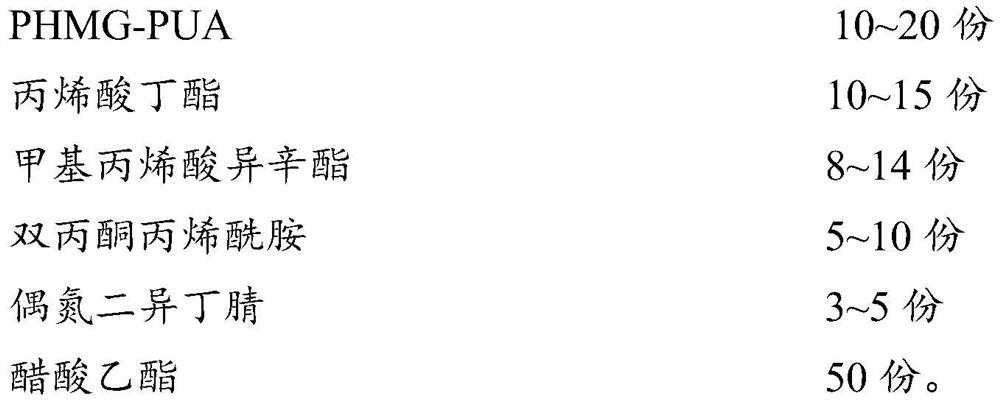

[0050] Among them, as a preferred solution of the preparation method of the glass explosion-proof film of the present invention, the antibacterial and antifungal oligomer resin is polyhexamethylene guanidine hydrochloride (PHMG) and methacrylic acid. Methylguanidine hydrochloride dimethylacrylamide oligomer resin (PHMG-DMAA), the specific preparation method of the PHMG-DMAA can be: polyhexamethyleneguanidine h...

Embodiment 1

[0065] A preparation method of a glass explosion-proof film with antibacterial and mildewproof effects, comprising the following steps:

[0066] (1) Preparation of antibacterial and mildew-proof oligomer resin:

[0067] Mix and feed polyhexamethyleneguanidine hydrochloride and methacrylic acid at a molar ratio of 1:2.01, add them into a 500ml four-neck flask, and control the temperature at 80±5°C, such as 75°C, 80°C, 85°C , adding boron trifluoride ether with a mass ratio of 0.01% as a catalyst, stirring for 6 hours, vacuumizing to remove small molecular substances generated in the condensation reaction, cooling to room temperature, adding ethyl acetate to dilute to a solid content of 50%, and synthesizing polyhexa Methylene guanidine hydrochloride dimethylacrylamide to obtain an antibacterial and antifungal oligomer resin.

[0068] (2) Preparation of UV photocurable coating composition containing antibacterial and mildew-proof oligomer resin:

[0069] Use the following part...

Embodiment 2

[0079] A preparation method of a glass explosion-proof film with antibacterial and mildewproof effects, comprising the following steps:

[0080] (1) Preparation of antibacterial and mildew-proof oligomer resin:

[0081] Mix and feed polyhexamethyleneguanidine hydrochloride and methacrylic acid at a molar ratio of 1:2.01, add them into a 500ml four-neck flask, and control the temperature at 80±5°C, such as 75°C, 80°C, 85°C , adding 0.01% boron trifluoride diethyl ether as a catalyst, stirring for 6 hours, and vacuumizing to remove small molecular substances generated in the condensation reaction. After cooling down to room temperature, ethyl acetate was added to dilute to a solid content of 50%, and polyhexamethyleneguanidine hydrochloride dimethylacrylamide was synthesized to obtain an antibacterial and antifungal oligomer resin.

[0082](2) Preparation of UV photocurable coating composition containing antibacterial and mildew-proof oligomer resin:

[0083] Use the following...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| antibacterial rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com