Glass fiber grid cloth production device

A glass fiber and production device technology, applied in printing, rotary printing machines, printing machines, etc., can solve the problems of no trademark embossing mechanism, redundant and complicated production devices, not suitable for mass production, etc., and achieve reasonable design and structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

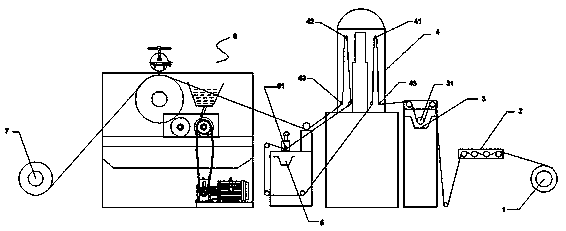

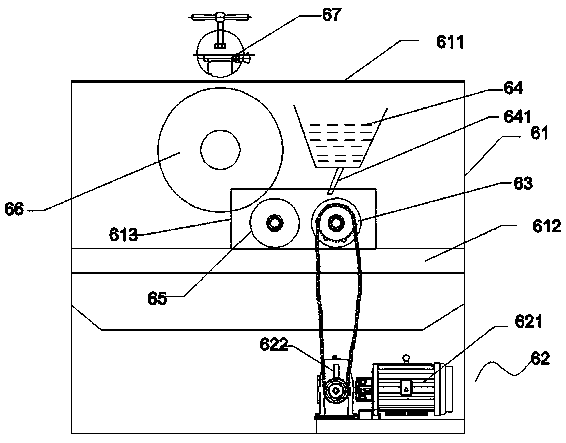

[0020] like figure 1 figure 2 A glass fiber mesh cloth production device shown includes an unwinding roller group 1, a tension adjusting roller group 2, a bottom rubber pool 3, a drying tower mechanism 4, a self-adhesive pool 5, a labeling mechanism 6 and a winding Roller 6; the unwinding roller group 1, the tension adjusting roller group 2, the bottom rubber pool 3, the drying tower mechanism 4, the self-adhesive pool 5, the pressing mechanism 6 and the winding roller 7 are arranged in sequence.

[0021] A set of unwinding rollers is set on a supporting base through a bearing seat, and a glass fiber mesh cloth is arranged on the unwinding roller set 1, and a number of glass fibers released from the unwinding roller set are wound on the tension adjusting roller set 2. Fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com