Automobile engine cylinder head with complex shape and device for detecting flaws and leakage of tightness of automobile engine cylinder head with complex shape

A technology for automotive engines and complex shapes, which is applied in the testing of fluid tightness, cylinder heads, engine components, etc. It can solve problems such as easy plugging, complex shapes, and difficulty in plugging methods, achieving high efficiency and reliable leak detection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

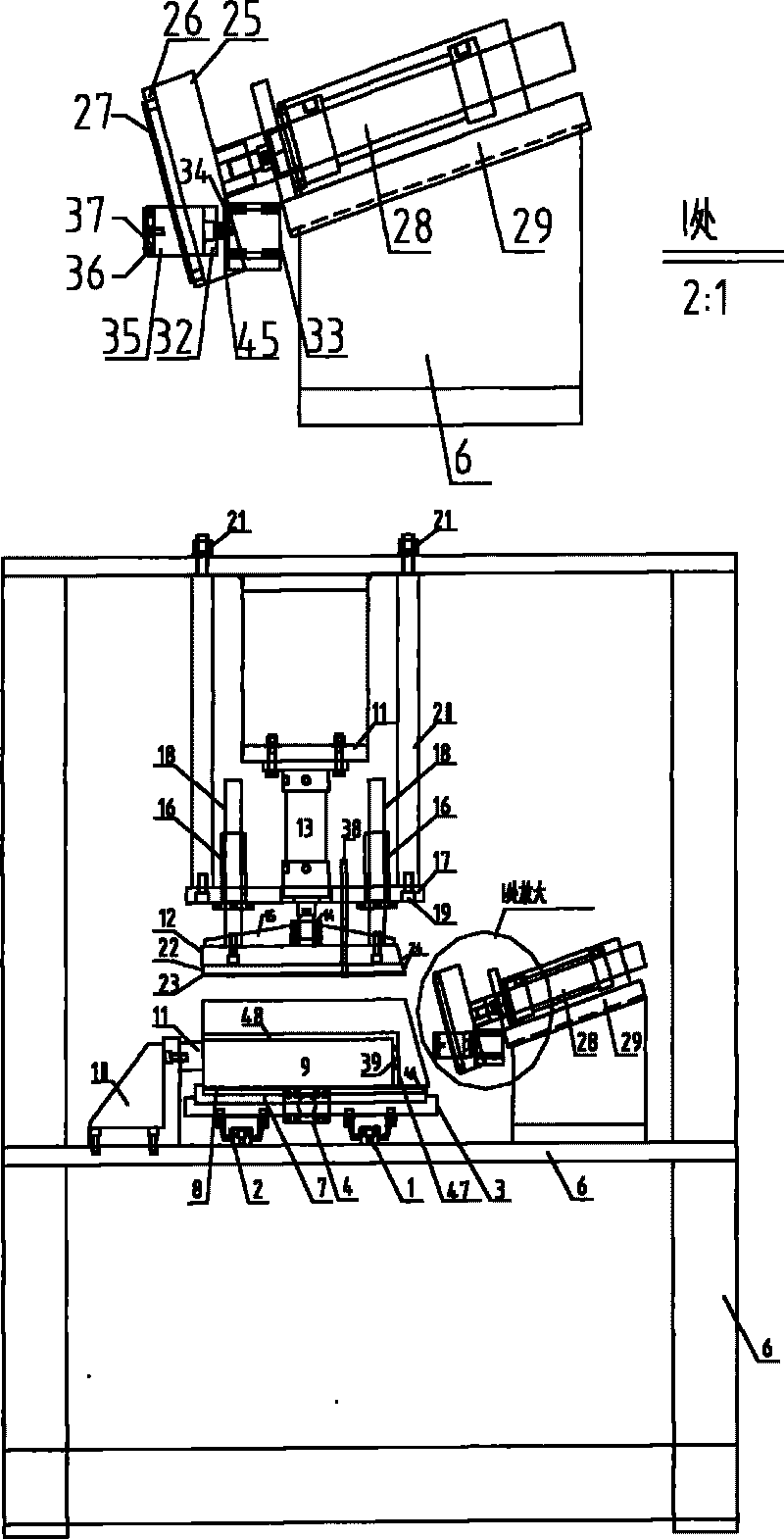

[0014] The present invention will be further described now in conjunction with accompanying drawing

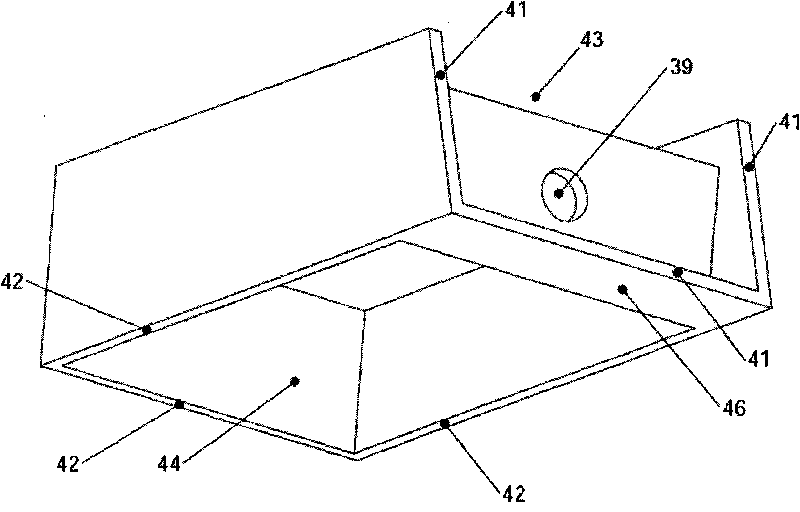

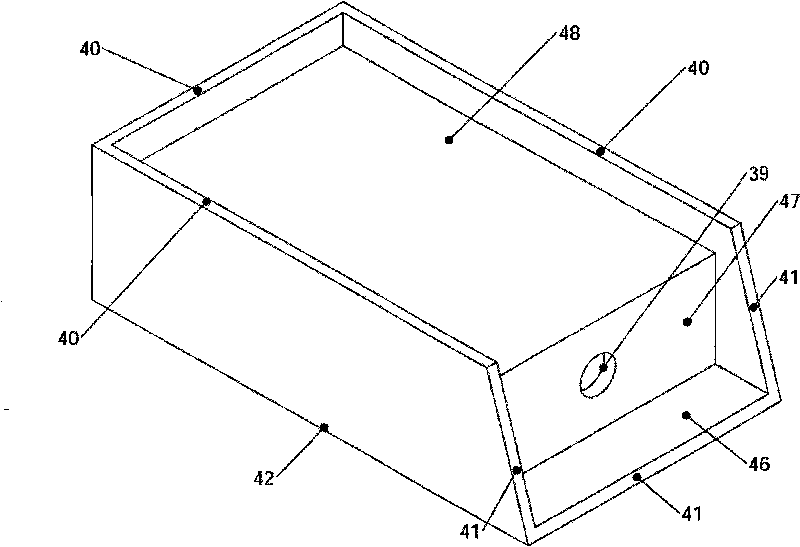

[0015] A complex-shaped automobile engine cylinder head, including a cover, its structure is: the engine cylinder head is a drawer-like bucket without a top cover surrounded by rectangular walls of equal height, and the drawer handle connected with two parallel straight walls is covered Remove it with an inclination, and shape it like a dustpan. The bottom surface of the dustpan leaves a long bottom surface 46 at the exit, and the other side of the long bottom surface 46 is hollowed out. The upper part has a parallel partition 48 and the vertical surface 47. The lower part forms a seal Cavity 44, dividing plate 48 tops and vertical face 47 right sides are sealed cavity 43, and vertical face 47 has through hole 39; Form the automobile engine cylinder head 9 of the complicated shape that three edge planes 40,41,42 surround as a whole.

[0016] The leak detection device for the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com