Magnetic levitation synchronous belt conveyor

A synchronous belt and magnetic levitation technology, applied in conveyors, non-mechanical conveyors, transportation and packaging, etc., can solve the problems of increased operation and maintenance costs, large energy consumption, noise, etc., and achieve low construction and maintenance costs and low production costs Reduced, low-noise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

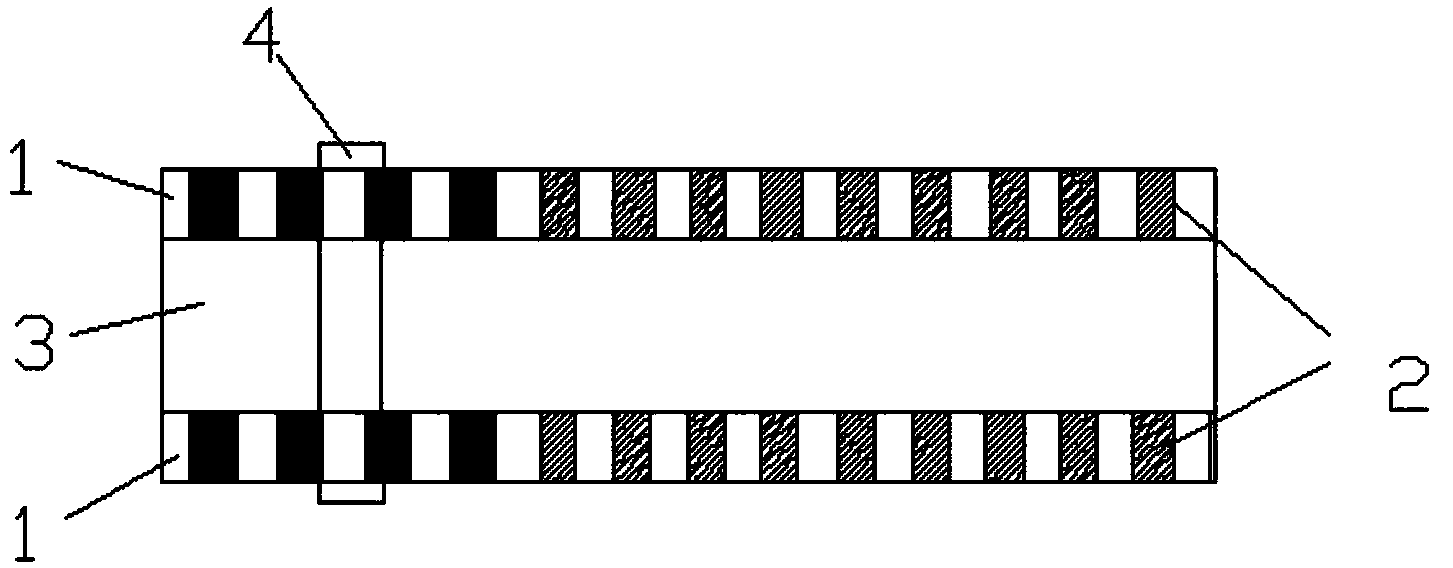

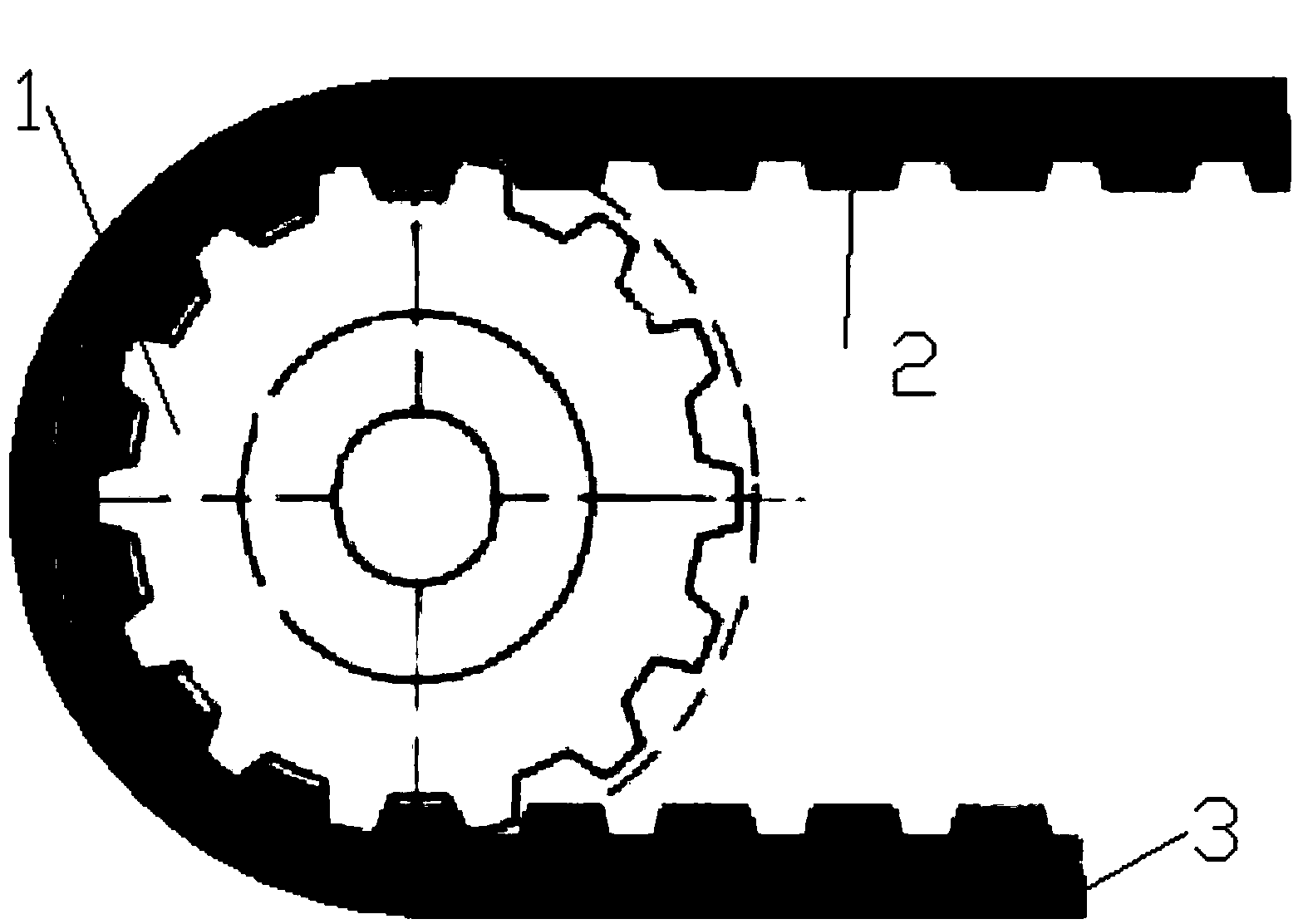

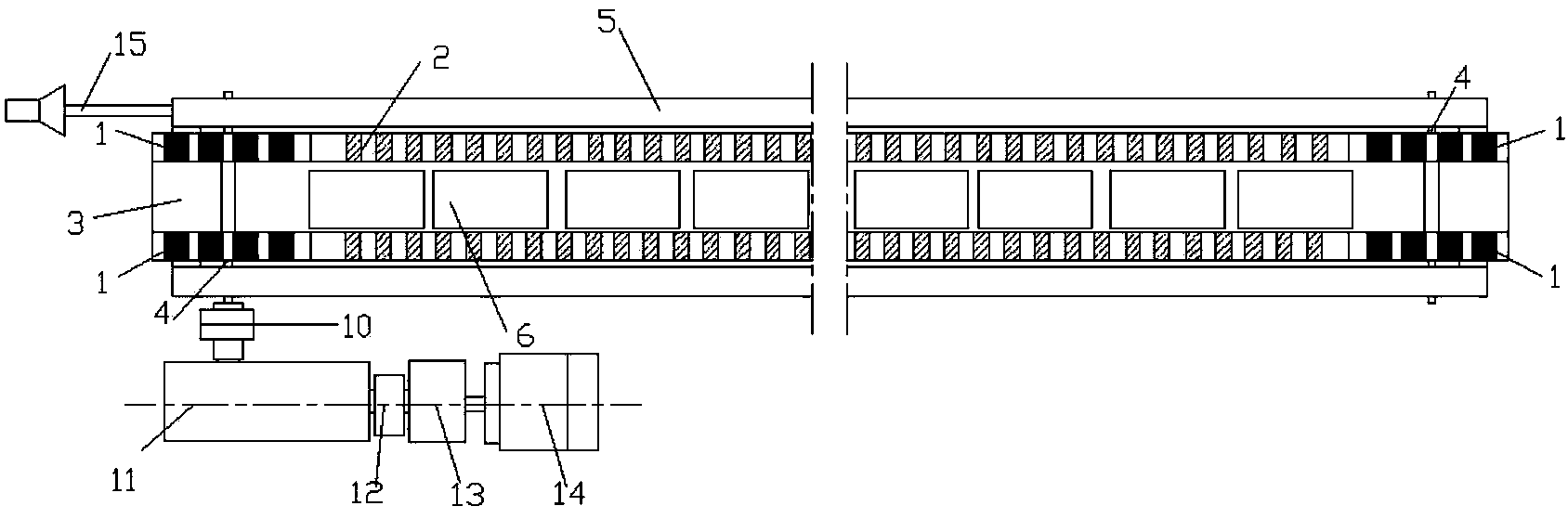

[0016] See attached figure 1 and attached figure 2 , a magnetic levitation synchronous belt conveyor, including a drive device, a transmission shaft 4, a synchronous pulley 1, a magnetic conveyor belt-permanent magnet suspension support device, a frame 5 and a return roller 9. The driving device is connected to the transmission shaft 4, and the transmission shaft 4 is driven to rotate; two synchronous pulleys 1 are arranged in parallel on the transmission shaft 4; the magnetic conveyor belt-permanent magnet suspension support device includes a conveyor belt 3, two Synchronous pulleys 1 arranged in parallel, permanent magnets 6, and permanent magnet support devices 7; the synchronous belts 2 are respectively wound on two parallel arranged synchronous pulleys 1, and the outer side of the synchronous belt 2 is fixed in the conveyor belt 3 surface; the two synchronous belts 2 are fixed on the edge of the inner surface of the conveyor belt 3 and arranged in parallel;

[0017] Se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com