Pretreatment method and treating machine for hogwash refuse of kitchen

A pretreatment machine and swill technology, which is applied in the technical field of kitchen swill treatment, can solve the problems of wasting resources, gasoline consumption, secondary pollution, etc., and achieves a small footprint, reduced transportation volume, and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described now in conjunction with accompanying drawing

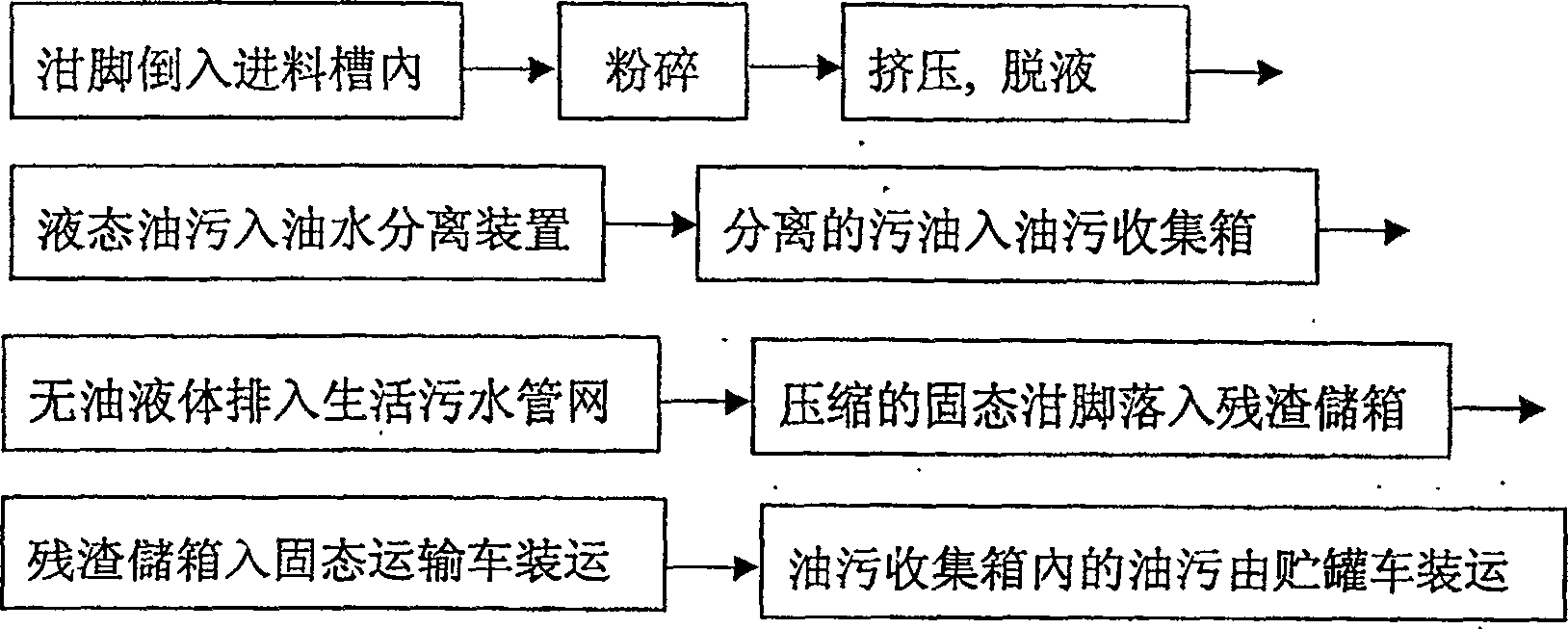

[0021] A method for pretreatment of kitchen swill garbage, which adopts the method of separating solid substances and liquid oily substances from kitchen swill, and realizes it by the following operations:

[0022] 1) Pour the swill into the feeding trough;

[0023] 2) crushing;

[0024] 3) extrusion, dehydration;

[0025] 4) Liquid oil enters the oil-water separation device;

[0026] 5) The separated dirty oil goes into the oil dirty collection box;

[0027] 6) The oil-free liquid is discharged into the domestic sewage pipe network;

[0028] 7) The compressed solid swill falls into the residue storage tank;

[0029] 8) The residue storage box is loaded into a solid-state transport vehicle for shipment;

[0030] 9) The oil in the oil collection box is transported by the tank truck.

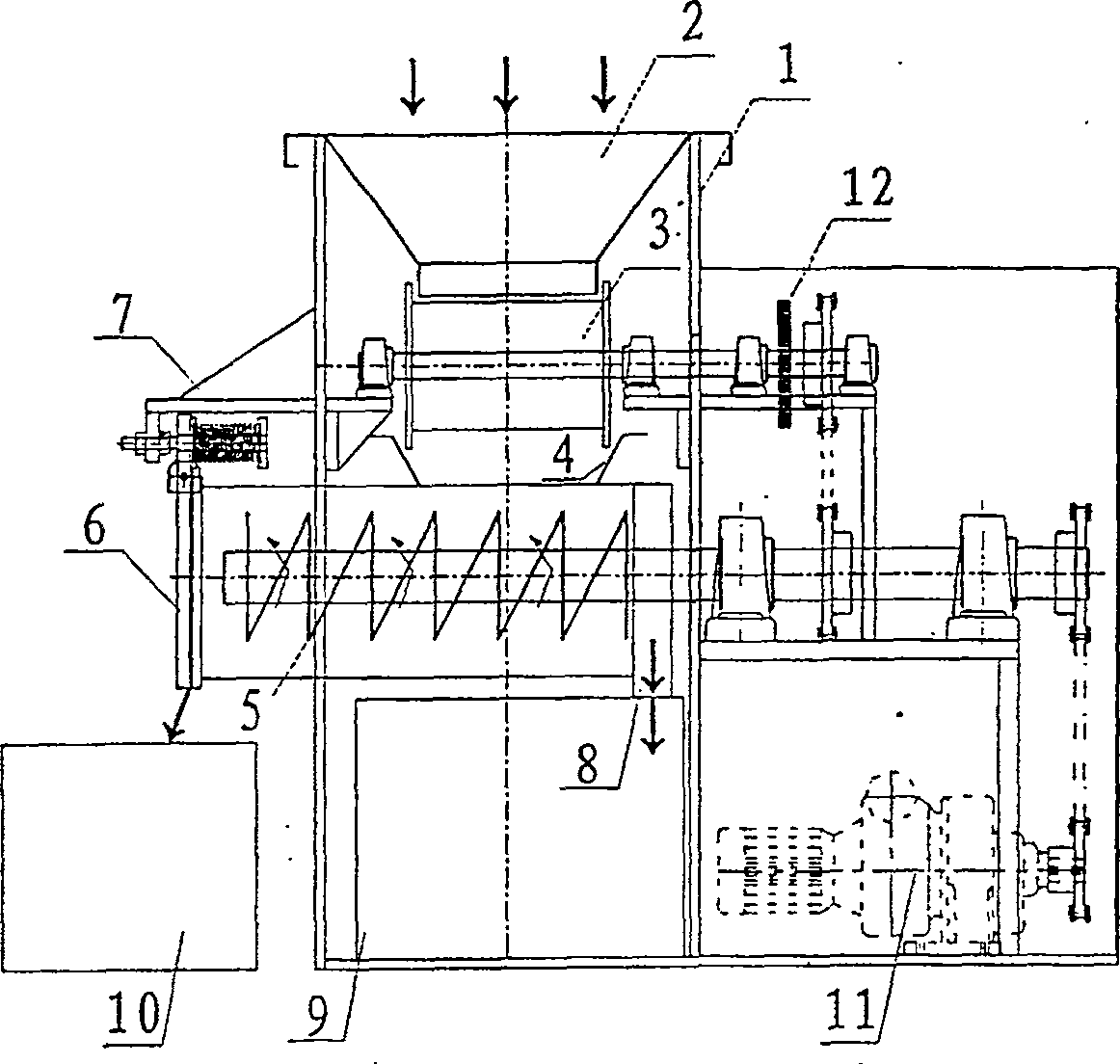

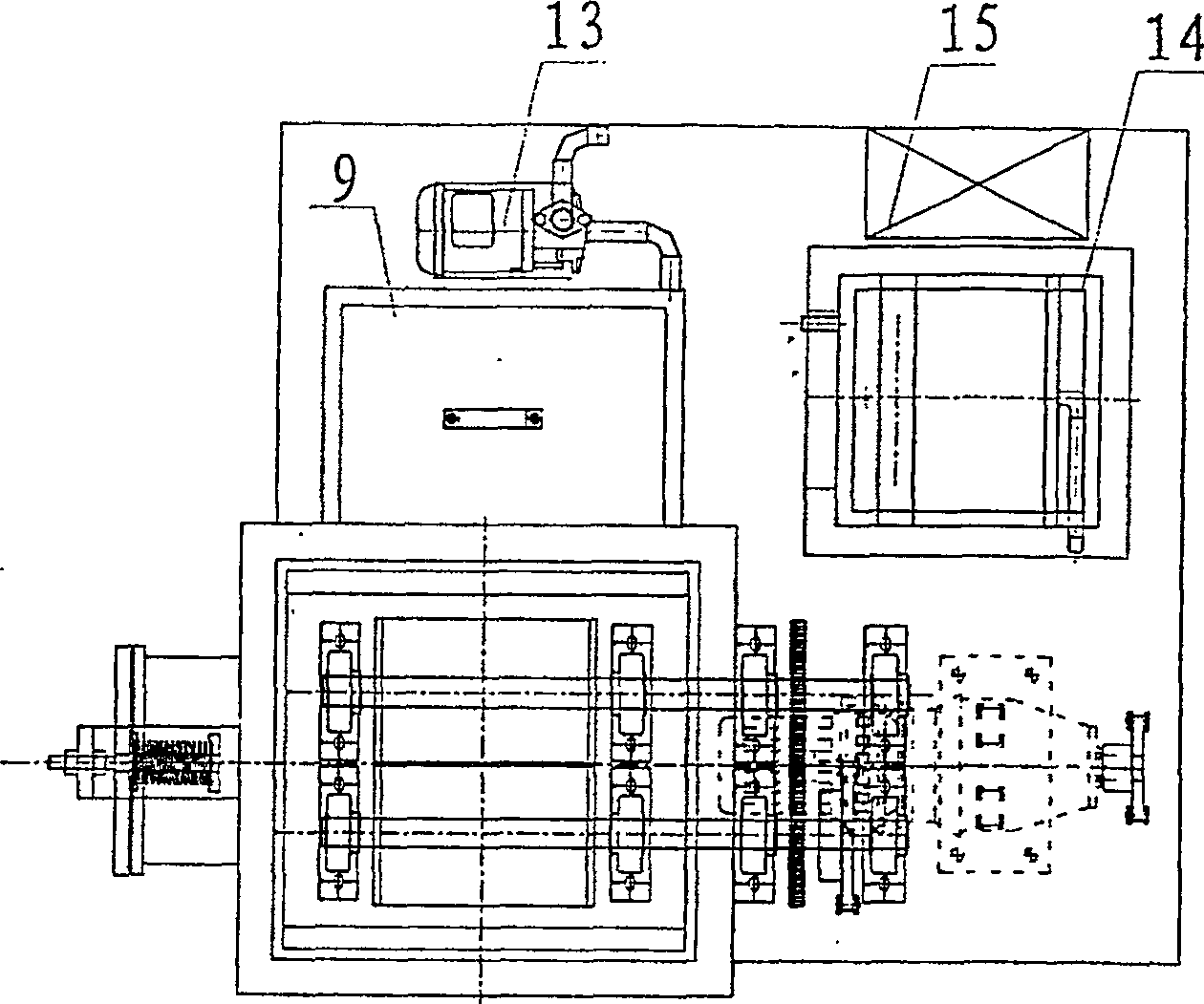

[0031] The above method is implemented by a preprocessing machine for kitchen slops. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com