Water tank water injection device of cleaning machine and cleaning machine

A cleaning machine and water tank technology, applied in the field of cleaning machines, can solve the problems of inconvenient use and high cost of water injection structure, and achieve the effect of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

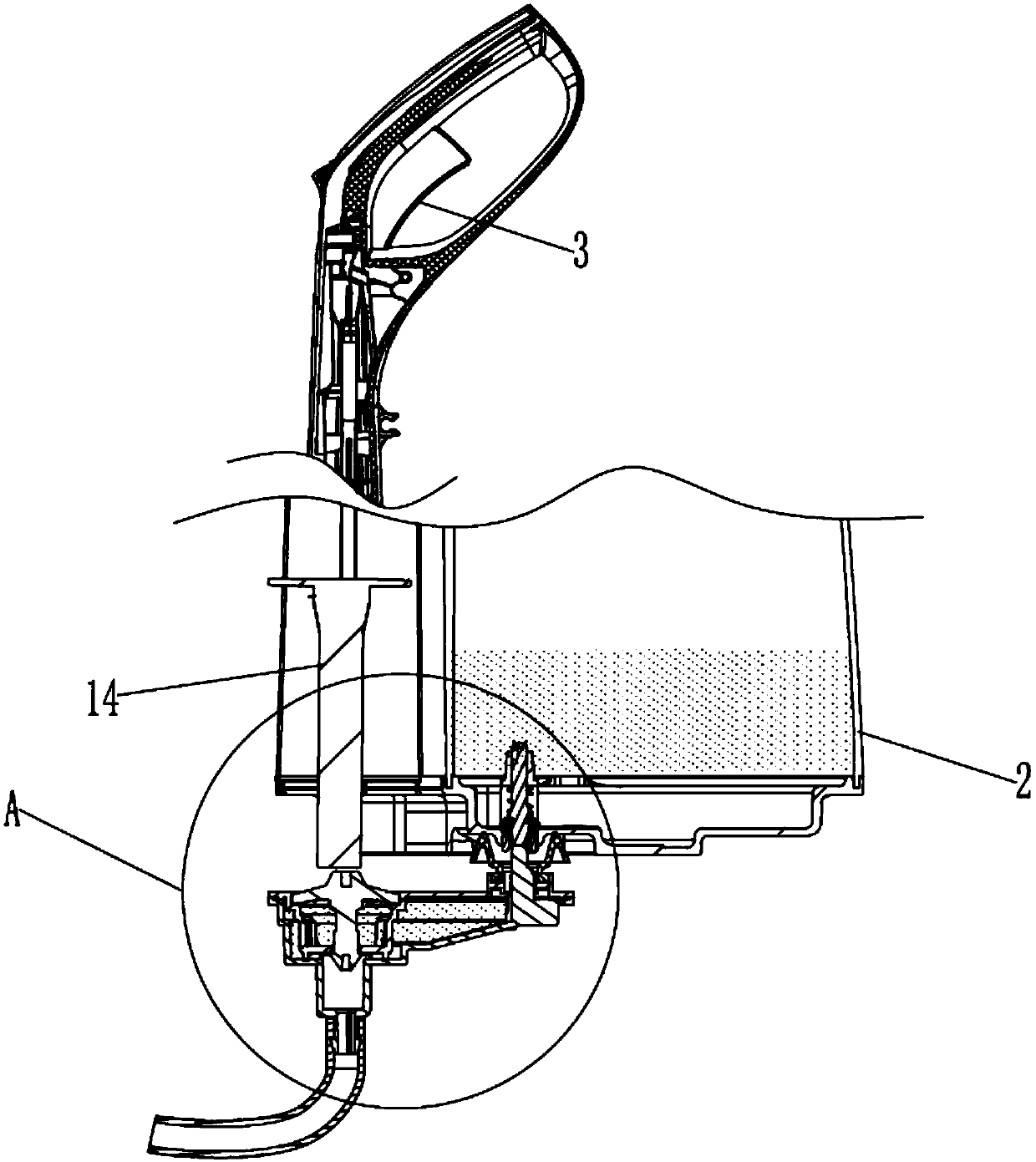

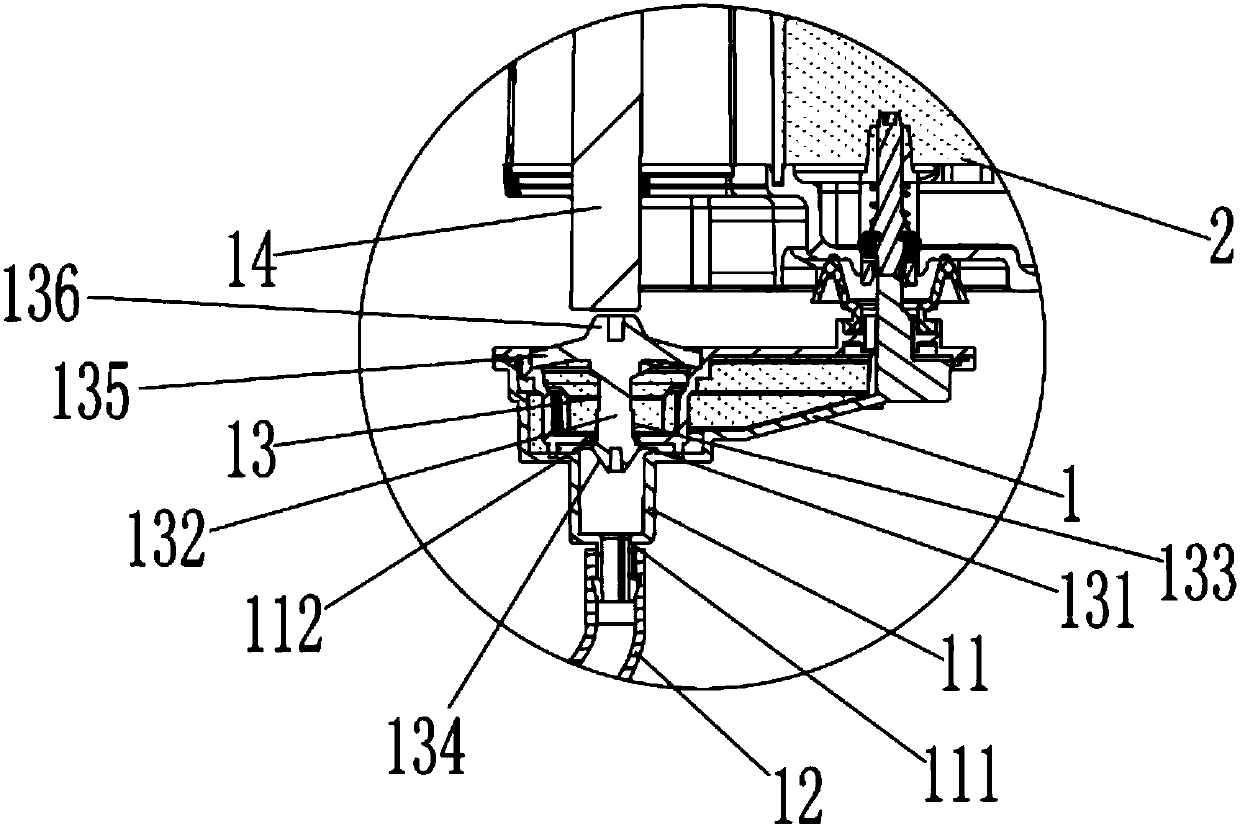

[0021] see Figure 1 to Figure 2 , the figure shows a water tank water injection device for a cleaning machine provided by Embodiment 1 of the present invention, which includes a water injection tank 1, which communicates with the water tank 2, and the water injection end 11 of the water injection tank 1 is connected to the water injection pipe 12, and the water injection end 11 The connection 111 with the water injection pipe 12 is provided with a movable sealing part 13, the sealing part 13 has a first sealing lip 131 sealing the connection 111, the first sealing part 13 contacts or connects with the pushing part 14, and the pushing part Specifically, 14 may be a push rod, and the pushing part 14 pushes the sealing part 13 to move toward the direction of the water injection pipe 12 . Wherein, the water injection tank 1 and the water tank 2 can be provided with valve parts to realize quantitative water discharge.

[0022] continue to see Figure 1 to Figure 2 , specifically...

Embodiment 2

[0026] see Figure 1 to Figure 2 , the figure shows a washing machine water tank water injection device and washing machine provided by Embodiment 2 of the present invention. On the basis of the above-mentioned embodiments, this embodiment further makes the following technical solutions as improvements: the first The surface of a sealing lip 131 is provided with a second sealing lip 133 arranged along the circumferential direction of the first sealing lip 131; a stepped surface structure is formed between the second sealing lip 133 and the first sealing lip 131, connecting The location 111 has a stepped surface 112 matched with the stepped surface structure. Through the setting of the above structure, the tightness of the connection can be guaranteed.

Embodiment 3

[0028] see Figure 1 to Figure 2 , the figure shows a washing machine water tank water injection device and washing machine provided by Embodiment 3 of the present invention. On the basis of the above-mentioned embodiments, this embodiment further makes the following technical solutions as improvements: the first The bottom of the two sealing protruding edges 133 forms a tapered end 134, which can utilize the movement of the valve stem to the bottom of the joint.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com