Steel rail drop hammer impact testing machine

A drop-weight impact test and rail technology, applied in the field of drop-weight impact test and rail drop-weight impact testing machine, can solve the problems of wasting manpower, increasing the weight of heavy hammers, reducing life and safety, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

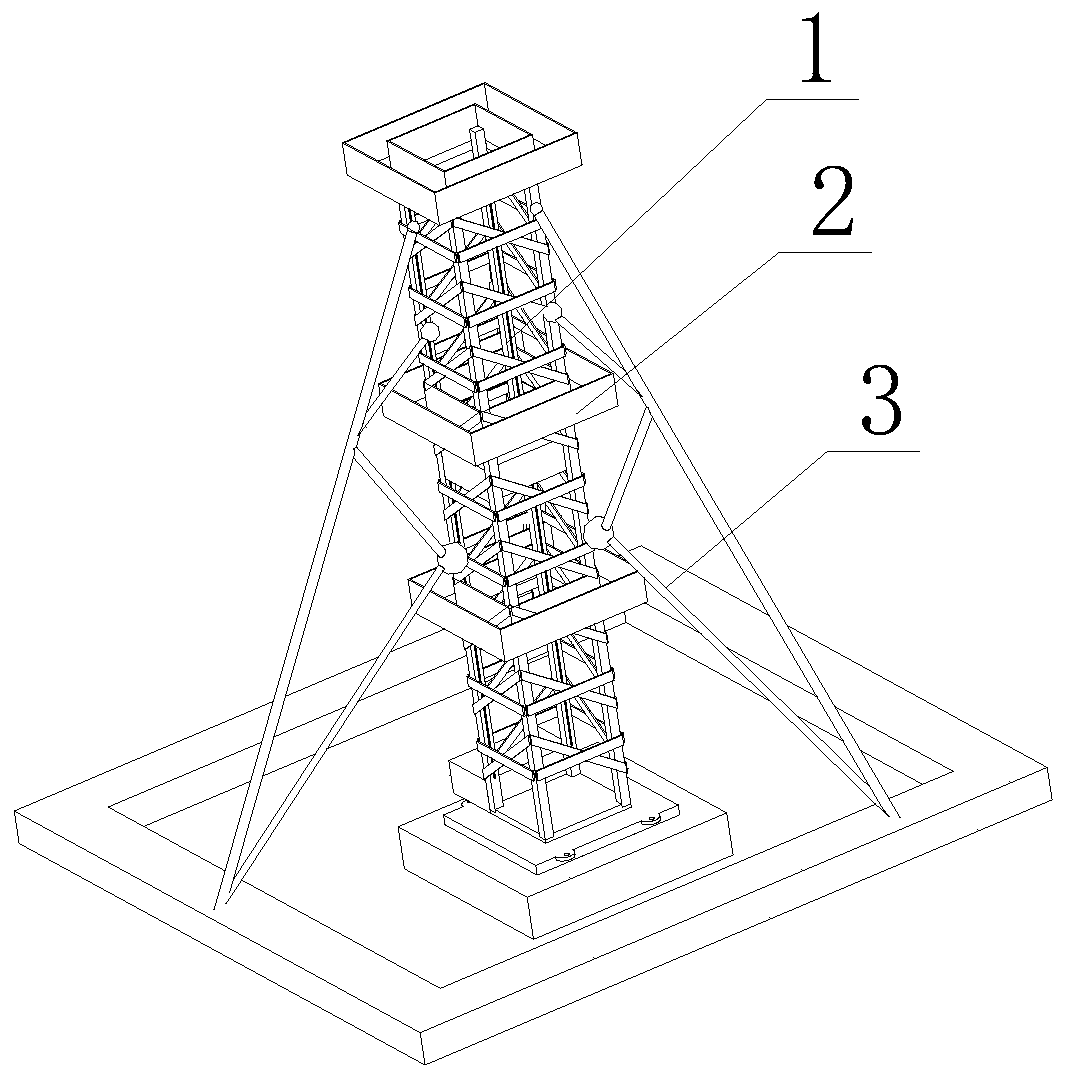

[0011] 1. See figure 1 , figure 2 , image 3 , Figure 4 , a rail drop weight impact testing machine of the present embodiment includes: a support 1, a workbench 2 and a side support 3, wherein the side support 3 is connected to the support 1 by welding to support the support 1 and prevent impact during work. Too large will cause the equipment to tilt and collapse. The workbench 2 and the support 1 are connected by welding, and the staff can climb to the workbench through the ladder on the support 1 to carry out maintenance and inspection of the equipment.

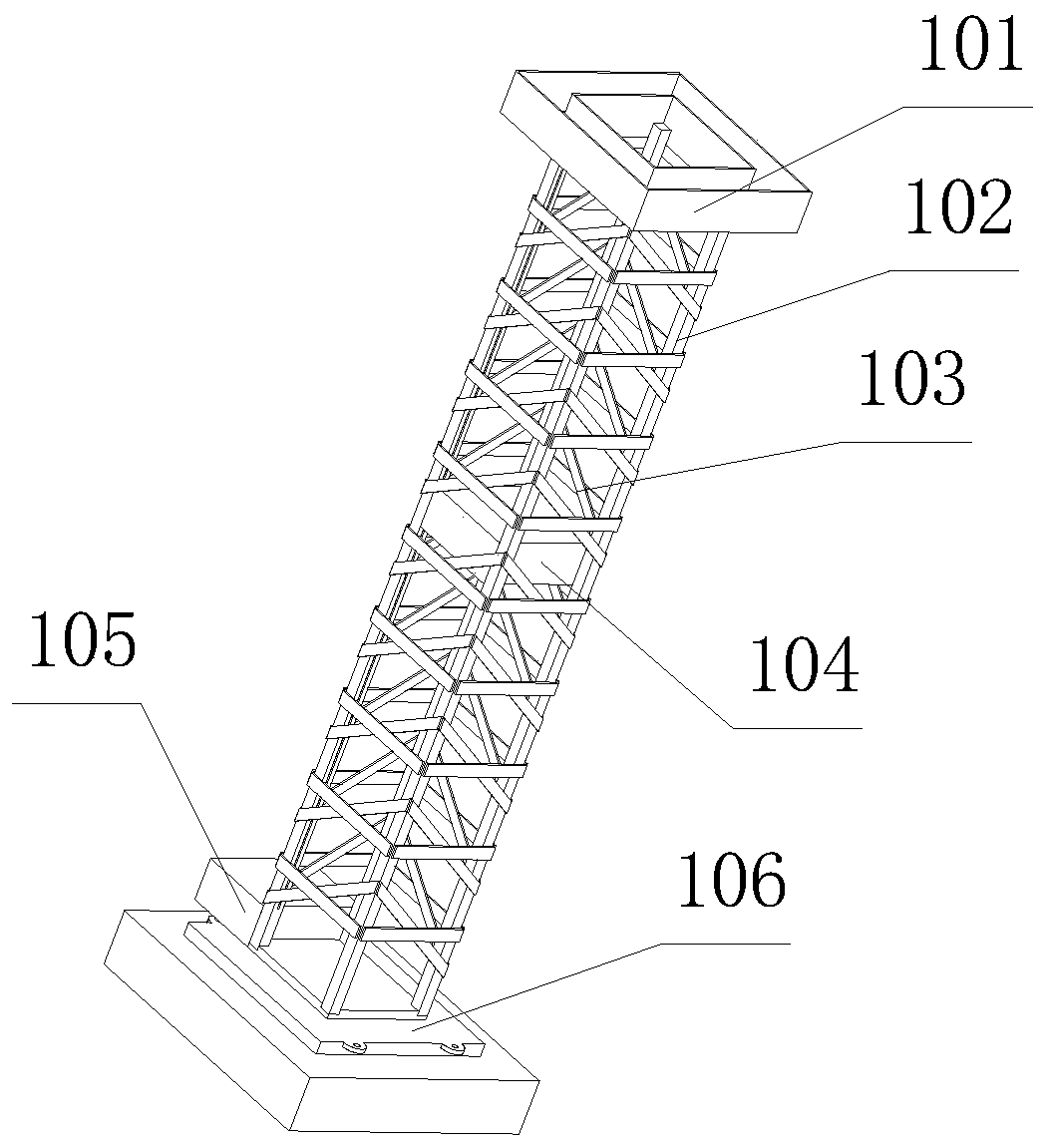

[0012] 2. See figure 2 , the support 1 is composed of a top workbench 101, a column 102, a support angle iron 103, a hammer head 104, a motor 105 and a floor 106, wherein the top workbench 101 is connected to the four upright columns 102 by welding, which is convenient for maintenance and detection of the staff. The supporting angle iron 103 is connected with the upright post 102 by welding to ensure the strength of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com