Automatic obstacle clearing equipment for lead wire

An automatic wire cleaning technology, applied in the field of electric power, can solve problems such as troublesome cleaning, fire, affecting wire transmission, etc., and achieve the effect of thorough cleaning, preventing equipment from tipping over, and preventing environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

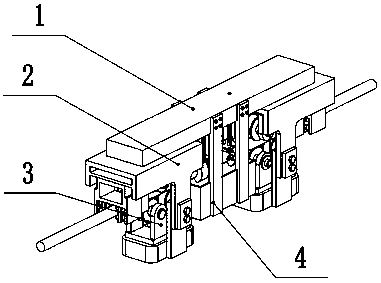

[0022] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 As shown in , a wire automatic obstacle removal equipment, including beam assembly 1, upper walking assembly 2, lower walking assembly 3, and collection box 4, is characterized in that: the lower part of the beam assembly 1 is fixedly installed on the upper walking assembly 2, and the lower walking assembly 2 Assembly 3 is installed below the upper walking assembly 2 by bolts, and the collection box 4 is installed on the beam assembly 1 by bolts.

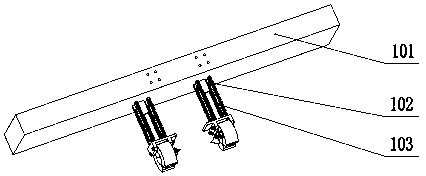

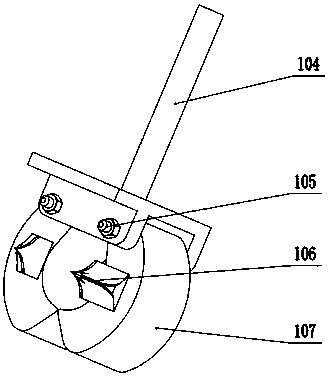

[0023] Further, the beam assembly 1 includes a cross arm 101, a first electromagnet 102, a first spring 103, a slide bar seat 104, a connecting shaft 105, a knife 106, a knife seat 107, and a ruler spring 108, and is characterized in that: The first electromagnet 102 and the first spring 103 are fixedly installed below the bearer 101, and the lower end of the first electromagnet 102 and the first spring 103 is fixedly installed on the upper surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com