A Miniaturized Horizontal Screw Extrusion Juicer with Easy Installation

A technology that is easy to install and juicer, applied in the direction of household machinery, kitchen utensils, household utensils, etc. for filtering food, can solve the problems of long axial length of the whole machine, unfavorable storage, easy blockage of filter holes, etc., to save axial The effect of occupying space, reducing juice filtering accessories, and improving the qualified rate of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

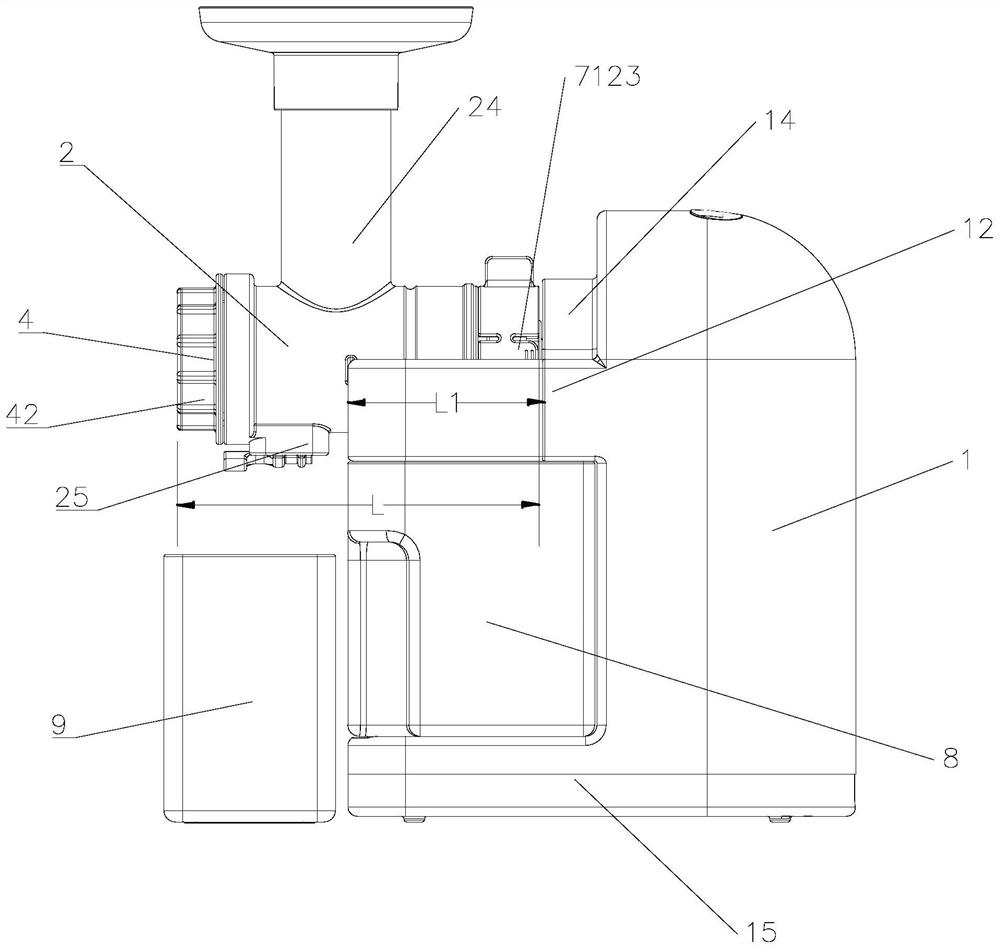

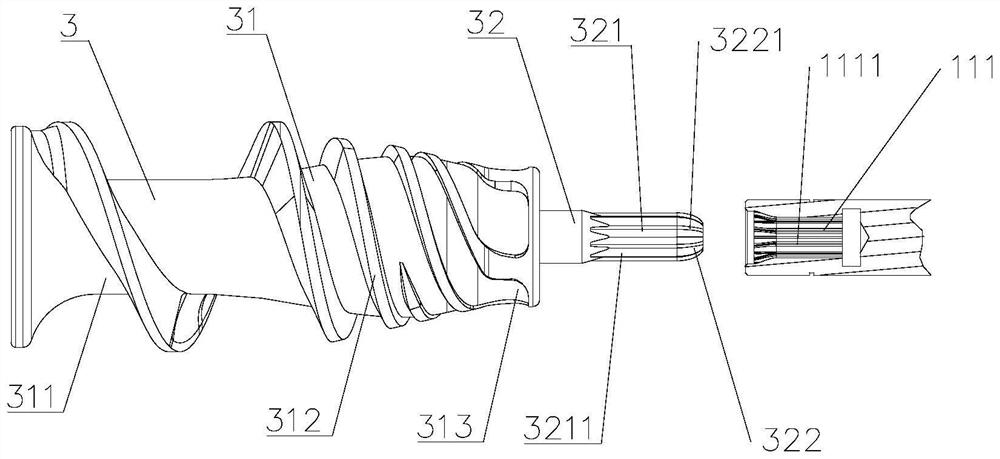

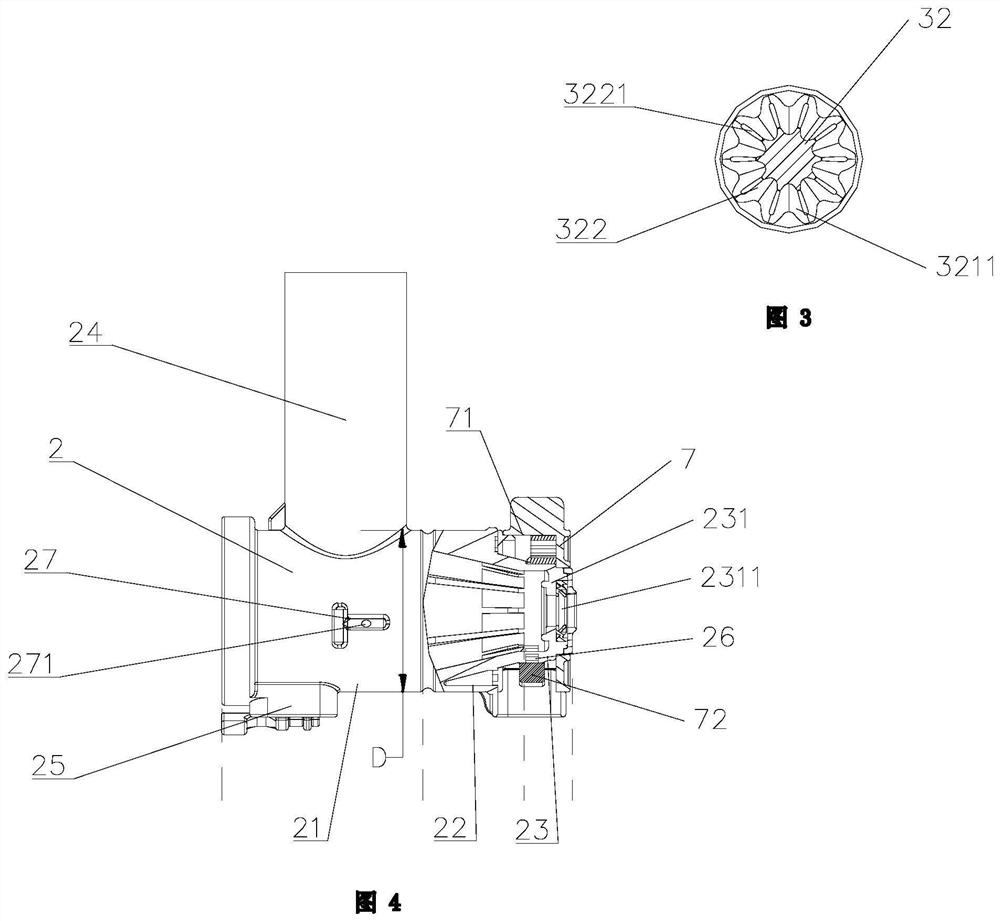

[0048] Such as Figure 1 to Figure 9 As shown, a miniaturized horizontal screw extrusion juicer with easy installation includes a machine base 1 and a pressing assembly connected with the machine base. A motor 11 is arranged in the machine base, and the motor includes a motor output shaft 111. The upper part of the seat is provided with a mounting seat 14, and the mounting seat 14 is provided with a mounting seat through hole 141 through which the shaft of the power supply passes. The pressing assembly includes an extraction cylinder 2, and a screw 3 arranged transversely in the extraction cylinder. The inner wall of the barrel cooperates to squeeze the juice. The screw 3 includes a screw body 31 and a screw shaft 32. The output shaft of the motor is connected to the screw shaft. One end of the extraction barrel 2 is provided with an end face 231, and the center of the end face is provided with a through hole 2311 for the screw shaft to pass through. , the other end is provide...

Embodiment 2

[0081] Such as Figure 10 and Figure 11 As shown, the difference between this embodiment and the first embodiment lies in that the structure of the pallet and the structure of the end cover are different. Specifically, the pallet includes an upper pallet 123 and a lower pallet 124, and the lower part of the upper pallet and the upper part of the lower pallet are enclosed to form the accommodating cavity 13, so that the upper pallet can be naturally transitionally connected with the upper end surface of the base , the overall shape of the base is more regular, and the upper pallet 123 and the lower pallet 124 are circumferentially arranged around the pressing assembly. The accommodating chamber includes an upper accommodating chamber 133 and a lower accommodating chamber 134, the upper accommodating chamber is formed by indenting the lower part of the upper pallet upward, the lower accommodating chamber is formed by indenting downward in the upper part of the lower pallet, an...

Embodiment 3

[0087] The difference between this embodiment and the first embodiment is that the supporting structure 12 is different from the pressing assembly, and the supporting platform 12 is also provided with an induction device 6 for detecting end caps. Such as Figure 12 As shown, one end of the extraction cylinder is connected to the base 1, and the other end is provided with an end cover 4, and the support platform extends forward to the end cover 4, and the support platform 12 is provided with an induction device 6, and the end cover 4 A trigger member 61 for triggering the sensing device is provided on it. The induction device is a magnetic switch, and the trigger on the end cover 4 is a magnet, which further ensures the safety of the whole machine. When the end cover is removed, the machine does not work, and the user cannot touch the running screw. Set like this when the juice receiving container is placed below the juice outlet, the machine base is a cube, and the structure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com