Exhaust gas purifying catalyst

A waste gas purification and catalyst technology, which is applied in the direction of physical/chemical process catalysts, catalyst activation/preparation, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of no research on pressure loss, pressure loss deterioration, and no exhaust gas purification Performance, OSC performance and pressure loss are presented at a high level to achieve the effect of optimizing exhaust gas purification performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0070] Hereinafter, the present invention will be described in more detail using examples. However, the technical scope of the present invention is not limited by these examples.

[0071] 1. OSC material

[0072] As the OSC material, ceria-zirconia (CeO 2 -ZrO 2 ) composite oxides.

[0073] Preparation of Ceria-Zirconia Composite Oxide (Pyrochlore ZC) with Pyrochlore Structure

[0074] will be CeO 2 49.1 g of a 28% by weight aqueous cerium nitrate solution in terms of ZrO 2 After dissolving 54.7 g of an aqueous zirconyl nitrate solution of 18% by weight in conversion and a commercially available surfactant in 90 mL of ion-exchanged water, 1.2 equivalents of NH were added to the anion. 3 In 25% by weight of ammonia water, a coprecipitate was generated, and the obtained coprecipitate was filtered and washed. Next, the obtained coprecipitate was dried at 110° C., and then fired at 500° C. in the air for 5 hours to obtain a solid solution of cerium and zirconium. Thereafte...

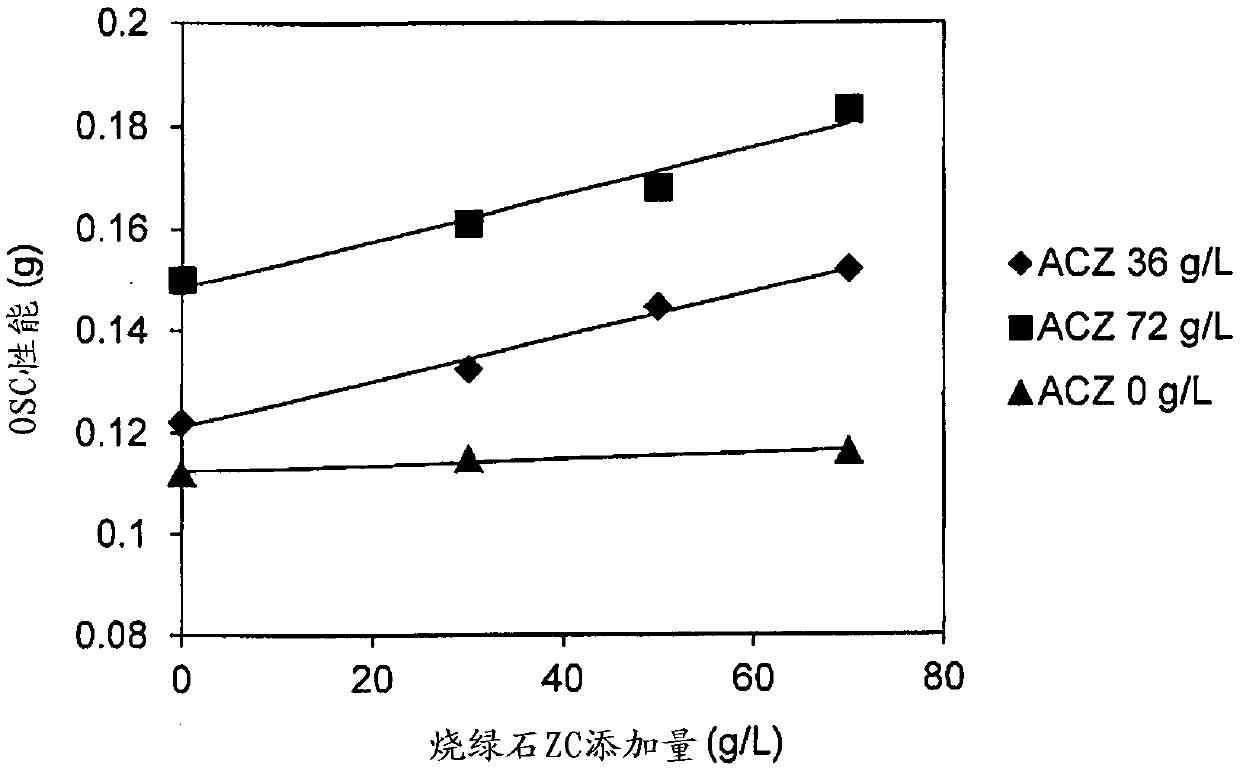

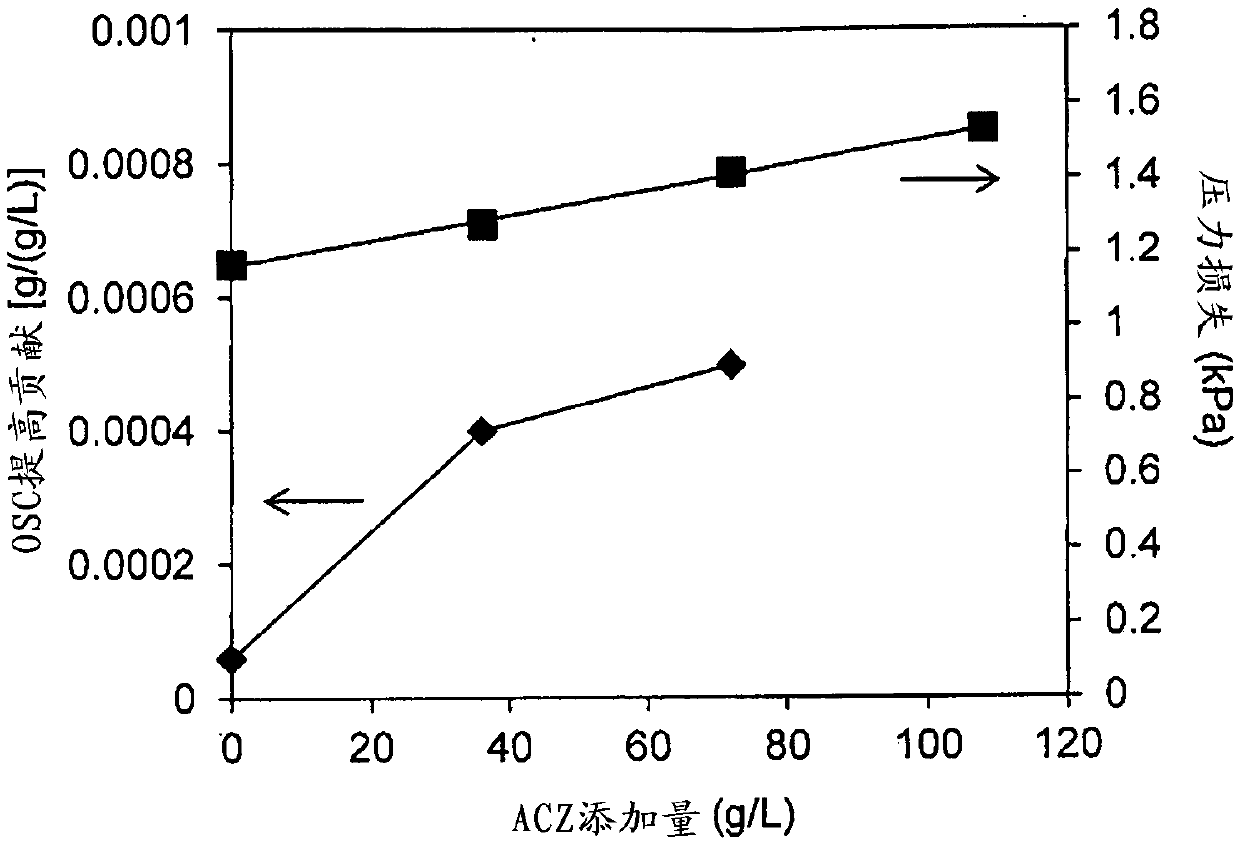

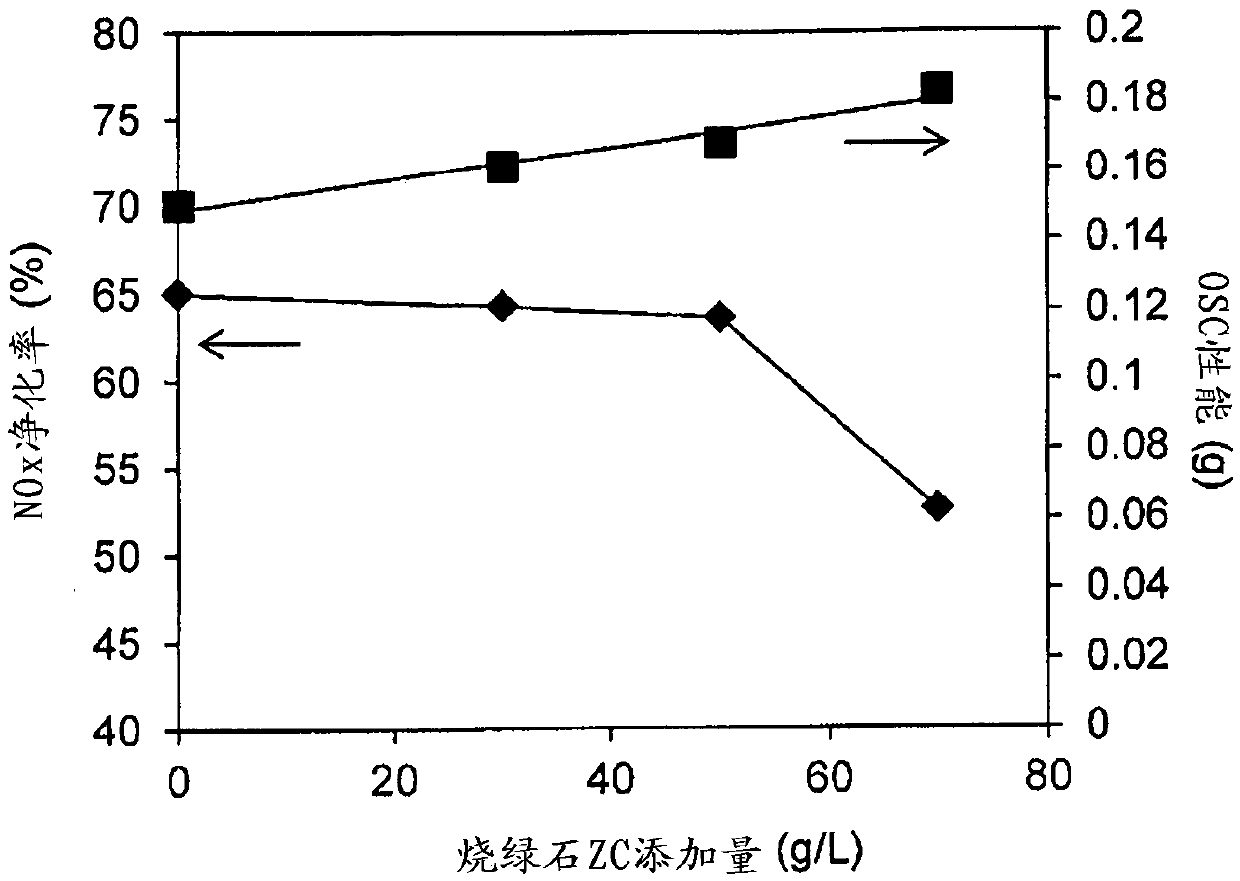

Embodiment 1、2 and comparative example 5

[0092] In Examples 1, 2, and Comparative Example 5, pyrochlore ZC was added to the slurry 2 for forming the upper layer of the catalyst coating so that the capacity relative to the substrate was 30 g / L, 50 g / L, and 70 g / L, respectively. Each catalyst was obtained in the same manner as in Comparative Example 4 except for the amount of L.

Embodiment 3、4 and comparative example 7

[0094] In Examples 3, 4, and Comparative Example 7, pyrochlore ZC was added to the slurry 2 for forming the catalyst coating layer of the upper layer, so that the capacity relative to the base material became 30 g / L, 50 g / L, and 70 g / L, respectively. Each catalyst was obtained in the same manner as in Comparative Example 6 except for the amount of L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com