Novel petroleum pipeline welding device

A technology for oil pipelines and welding equipment, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as single function and inconvenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

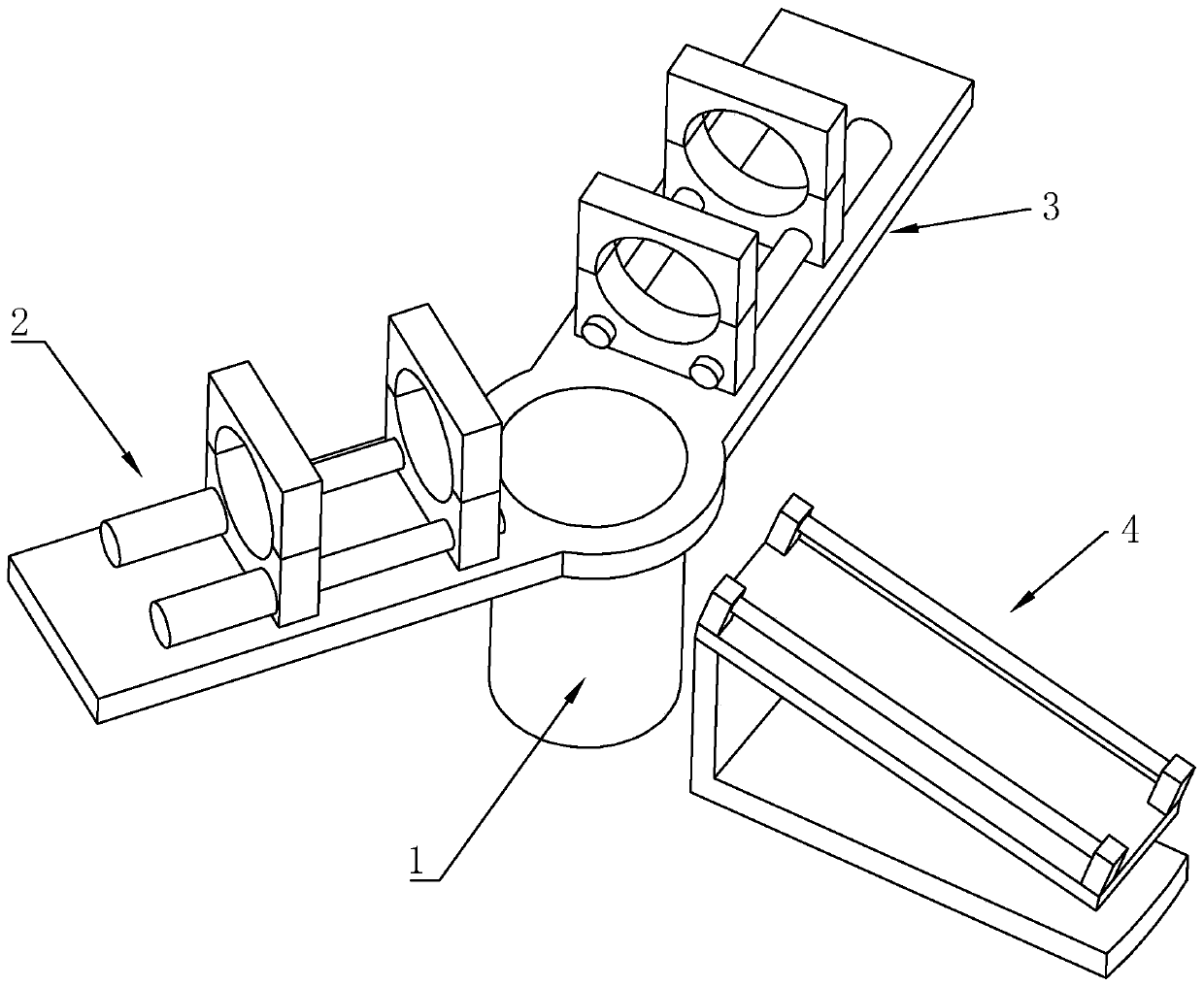

Embodiment 1

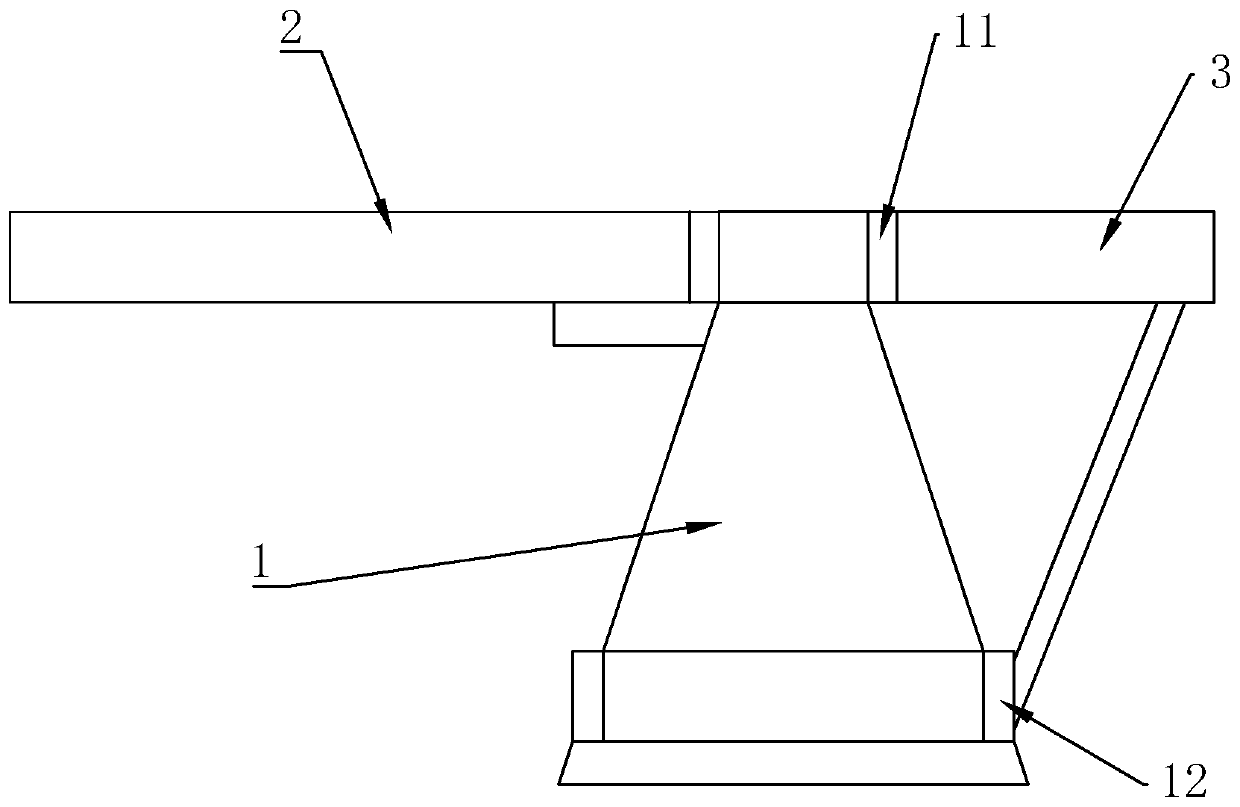

[0023] The jacket includes a lower jacket and an upper jacket. The upper jacket and the lower jacket are spliced to form a round hole for the straight pipe to be put in. The straight pipe moving mechanism is set as the No. 1 hydraulic cylinder. The cylinder body of the No. 1 hydraulic cylinder and the straight pipe The support is fixedly connected, the piston rod is fixedly connected with the lower jacket, and the lower jacket is slidably connected with the straight pipe support.

Embodiment 2

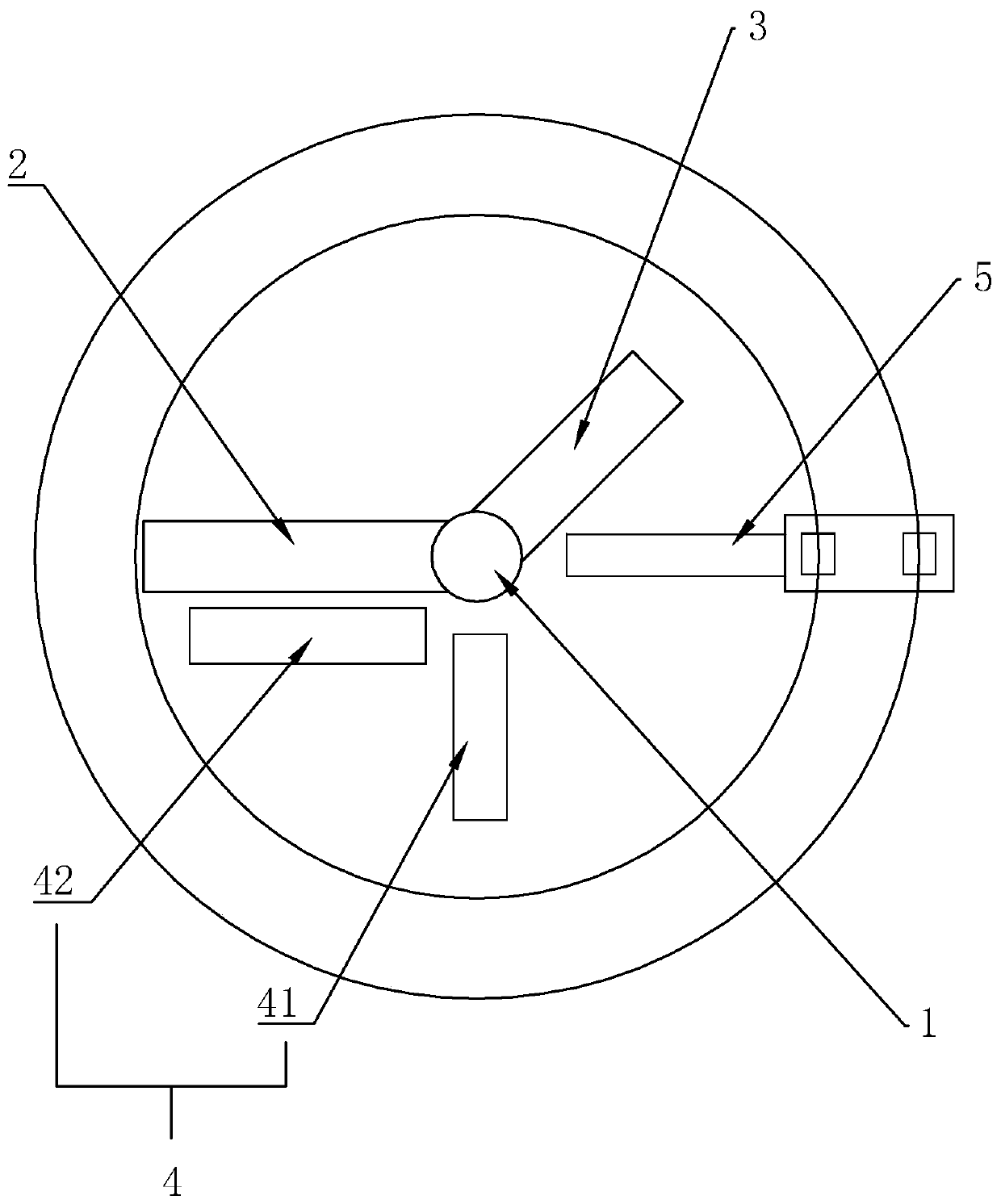

[0025] The jacket includes a fixed jacket and a semicircular support jacket. The fixed jacket includes a lower jacket and an upper jacket. The upper jacket and the lower jacket are spliced to form a round hole for straight pipes. The lower jacket is fixed on On the straight pipe support, the straight pipe moving mechanism includes a No. 1 hydraulic cylinder, a slide block and a slide table, the slide table is fixedly connected along the length direction of the straight pipe support, the slide block is slidingly connected with the slide table, and the support jacket is fixed on the slide block.

[0026] The takeover cutting device 4 includes a support mechanism 41 and a cutting mechanism 42. The support mechanism 41 includes a cutting bracket, No. 2 hydraulic cylinder, No. 3 hydraulic cylinder, and a support seat. The cutting bracket is set to an L shape and is made of triangle steel welding. Including the bottom plate and the vertical plate, the bottom plate is placed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com