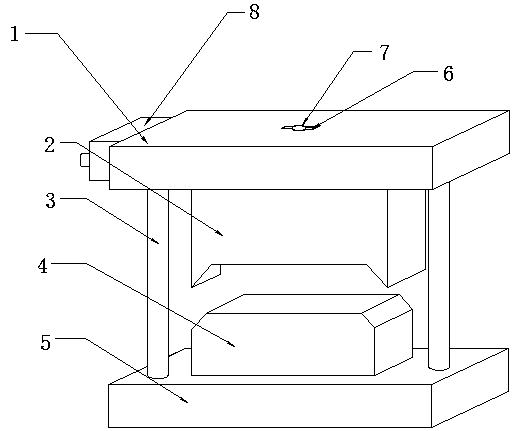

Automobile interior trim part injection mold

A technology for automotive interior parts and injection molds, which is applied to household components, household appliances, other household appliances, etc., can solve the problems of incomplete removal of residual materials, unclean air discharge, and increase of residual product rate, etc., to achieve residual material removal. Good effect, high product qualification rate, easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

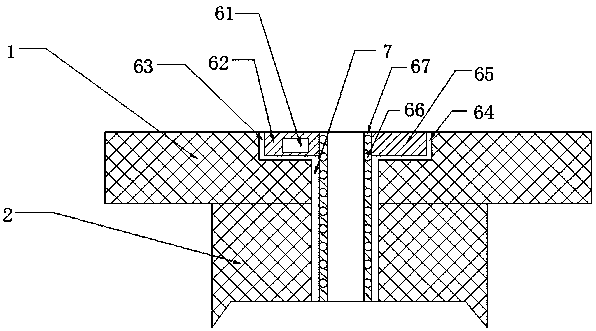

[0024] Specific implementation method: when there is residual material in the hollow column 67 that needs to be removed, the operator turns on the heating switch, the battery 61 transmits the electric energy to the resistance wire 66, and the resistance wire 66 converts the electric energy into heat energy, and the residual material absorbs heat energy, and the temperature rises. The residual material dissolves and starts to flow downward, and the operator uses a container to collect the flowing residual material until no residual material flows out, thus realizing the function of heating the residual material and facilitating the removal of the residual material.

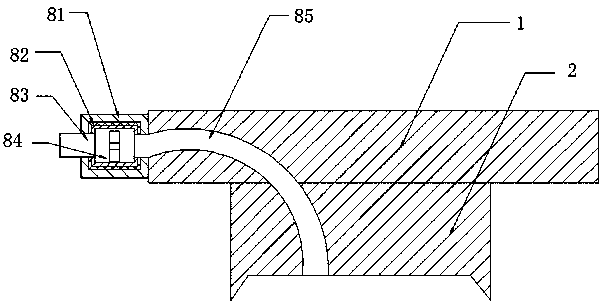

[0025] When the present invention started to work, when the movable mold core 2 and the fixed mold core 4 formed the injection cavity, the exhaust fan 84 was operated, and the exhaust fan 84 produced suction, and the air in the injection cavity was sucked into the exhaust fan 84 through the suction pipe 85, Then the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com