Novel winch rope cable

A rope and winch technology, applied in the field of new winch ropes, can solve the problem of insufficient strength of the winch cable, and achieve the effects of good use, enhanced wear resistance and good strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

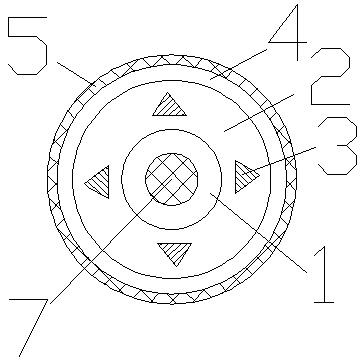

[0013] A new type of winch rope, comprising a rope core 1, a reinforcement layer 2 is arranged outside the rope core 1, and a reinforcement 3 is arranged inside the reinforcement layer 2, and the reinforcement 3 is made of a plurality of thin high-strength fibers The reinforcement layer 2 is provided with a braided mesh layer 4 outside, and a protective rubber layer 5 is arranged outside the braided mesh layer 4 .

[0014] The braided mesh layer 4 is provided with a braided mesh, and the braided mesh is a steel wire mesh.

[0015] A laser area 6 is arranged outside the protective rubber layer 5, and the date and the cable type are sprayed on the laser area 6.

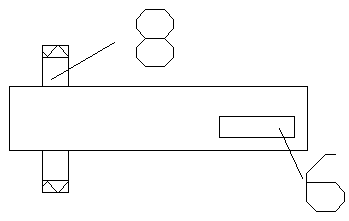

[0016] The cable core 1 is a rubber cable core, and a steel cable core 8 is arranged inside the cable core 1 .

Embodiment 2

[0018] A new type of winch rope, comprising a rope core 1, a reinforcement layer 2 is arranged outside the rope core 1, and a reinforcement 3 is arranged inside the reinforcement layer 2, and the reinforcement 3 is made of a plurality of thin high-strength fibers The reinforcement layer 2 is provided with a braided mesh layer 4 outside, and a protective rubber layer 5 is arranged outside the braided mesh layer 4 .

[0019] The braided mesh layer 4 is provided with a braided mesh, and the braided mesh is a steel wire mesh.

[0020] A laser area 6 is arranged outside the protective rubber layer 5, and the date and the cable type are sprayed on the laser area 6.

[0021] The cable core 1 is a rubber cable core, and a steel cable core 8 is arranged inside the cable core 1 .

[0022] The protective rubber layer 5 is provided with a wear-resistant ring 9, the wear-resistant ring 9 is a rubber ring, and the rubber ring 9 is provided with a corundum coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com