High-frequency variable displacement volume fracturing method for atmospheric pressure shale gas reservoir

A technology for shale gas reservoirs and volume fracturing, which is applied in the fields of fluid production, earth-moving drilling, wellbore/well components, etc., can solve the problems of reducing the complexity of fracturing fractures, low production and production, low production, and fast decline rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

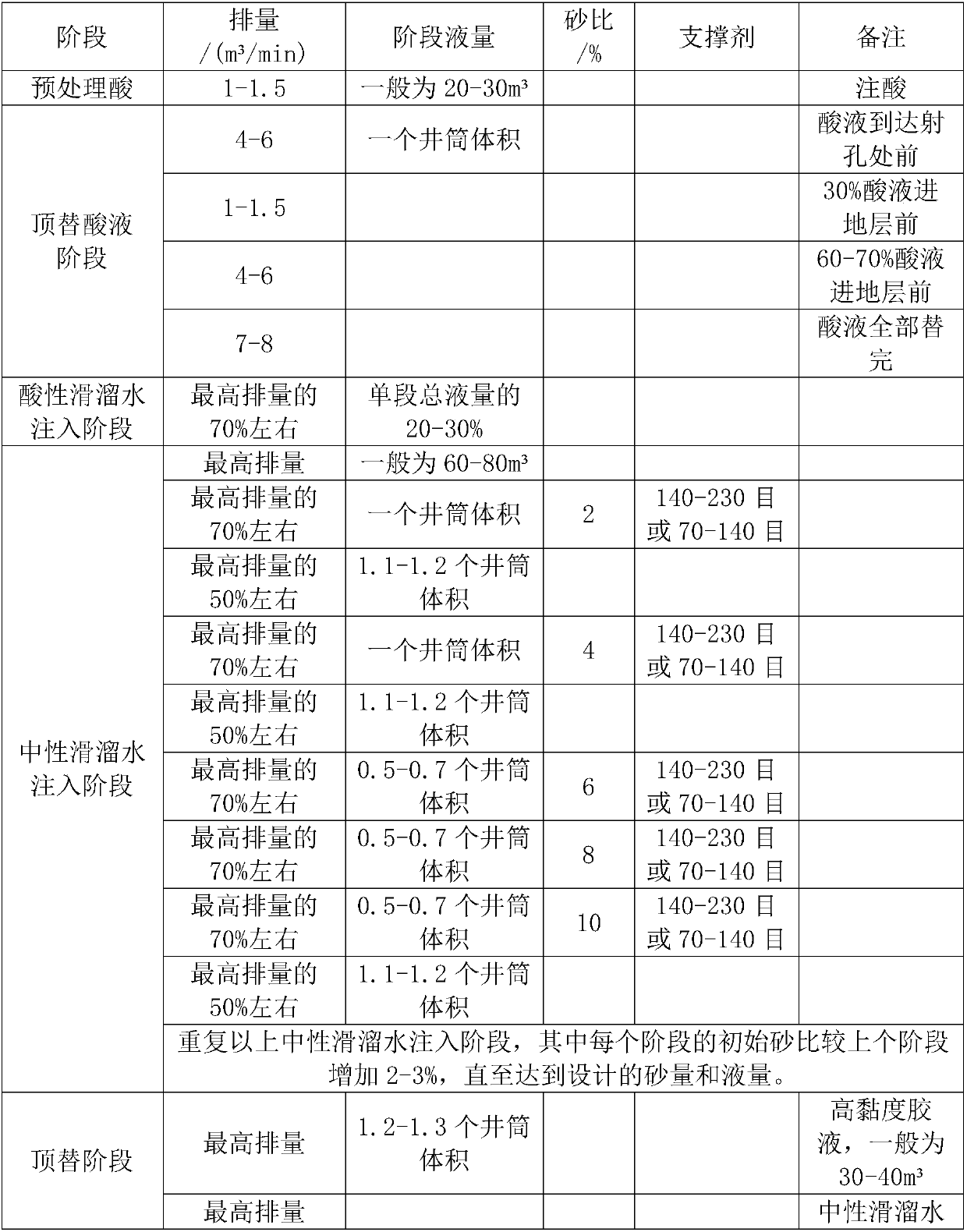

Method used

Image

Examples

Embodiment

[0083] A well in an atmospheric shale block has a vertical depth of 3876m, a sounding depth of 4932m, and a horizontal section of 1295m. The optimized design is carried out by the method provided by the present invention, and the steps and results are as follows:

[0084] (1) The evaluation of key shale reservoir parameters believes that the well has developed high-quality shale, with good static indicators, moderately high brittleness, and high-angle natural fractures in some sections.

[0085] (2) Determine the dual dessert area for geological desserts and engineering desserts (comprehensive desserts> 0.5) As the perforation cluster position.

[0086] (3) Establish a gas reservoir numerical simulation model, and use the orthogonal scheme to design the simulation scheme. The fracturing parameters for the long-term production after obtaining the optimal fracturing are as follows: fracturing 18 segments, the optimal fracture spacing of the main fractures is 14-22m, and the fracture ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com