Precision machining processing progress tracking method

A technology of production progress and precision machinery, applied in the field of mechanical processing, can solve problems such as insufficient control, increased production costs, economic losses, etc., and achieve the effect of speeding up the integration of features, improving efficiency, and increasing rigor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

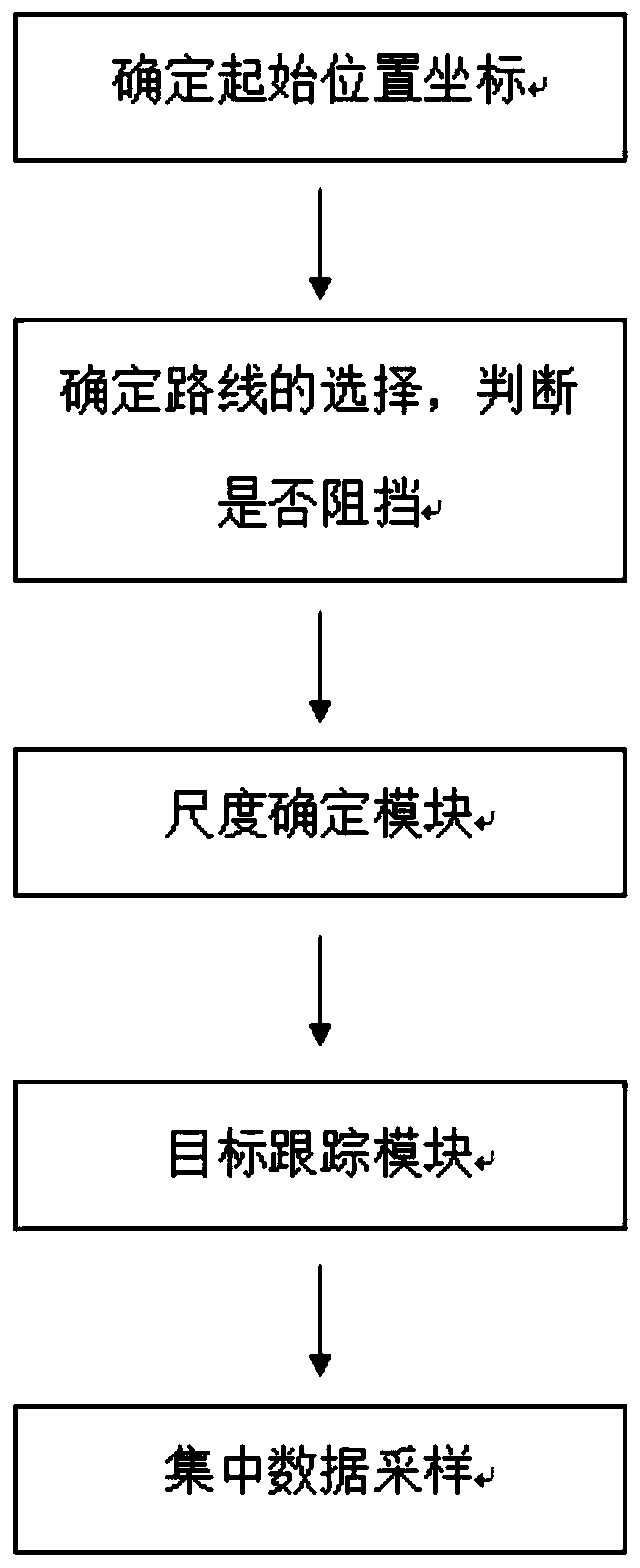

[0021] like figure 1 A method for tracking production progress of precision machining, the specific steps of which are as follows:

[0022] Step 1: Determine the starting position coordinates

[0023] Place the camera at a suitable height and position, adjust the computer, detection coil and digital acquisition card, and then set up the initial detection point to determine the initial position target.

[0024] Step 2: Determine the choice of route and judge whether it is blocked

[0025] First debug the camera to see if there is any obstruction when shooting the production progress of precision machining, which will lead to uncertainty in data collection and hinder the effectiveness of subsequent data collection.

[0026] Step 3: Scale Determin...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap