Lubrication structure of locomotive motor bearing

A technology for motor bearings and lubricating structures, applied in the direction of electromechanical devices, bearing components, shafts and bearings, can solve problems such as bearing system pollution, economic losses, and gearbox oil treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation, structure, features and effects of the present invention will be described in detail below in conjunction with the accompanying drawings and examples.

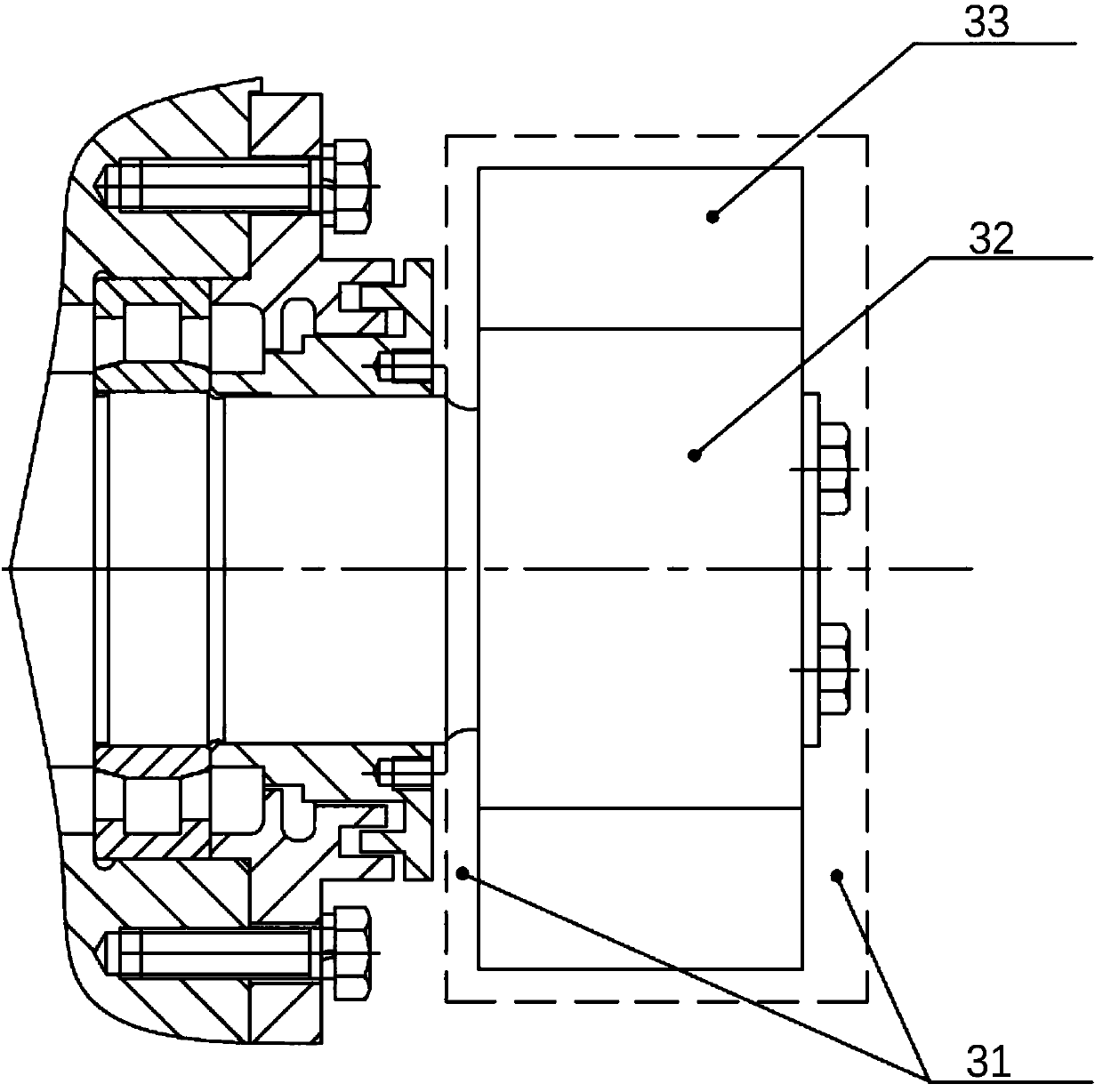

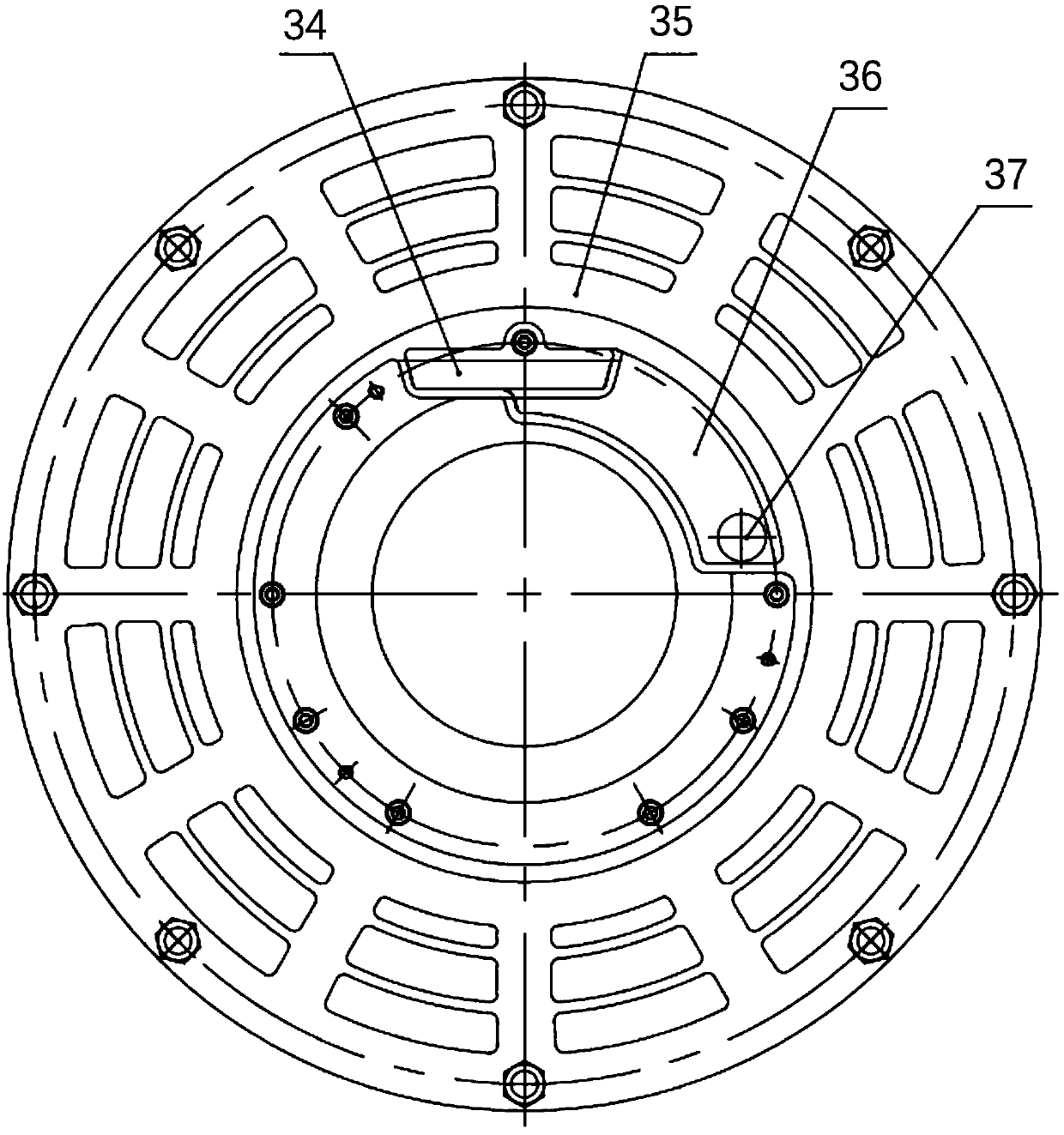

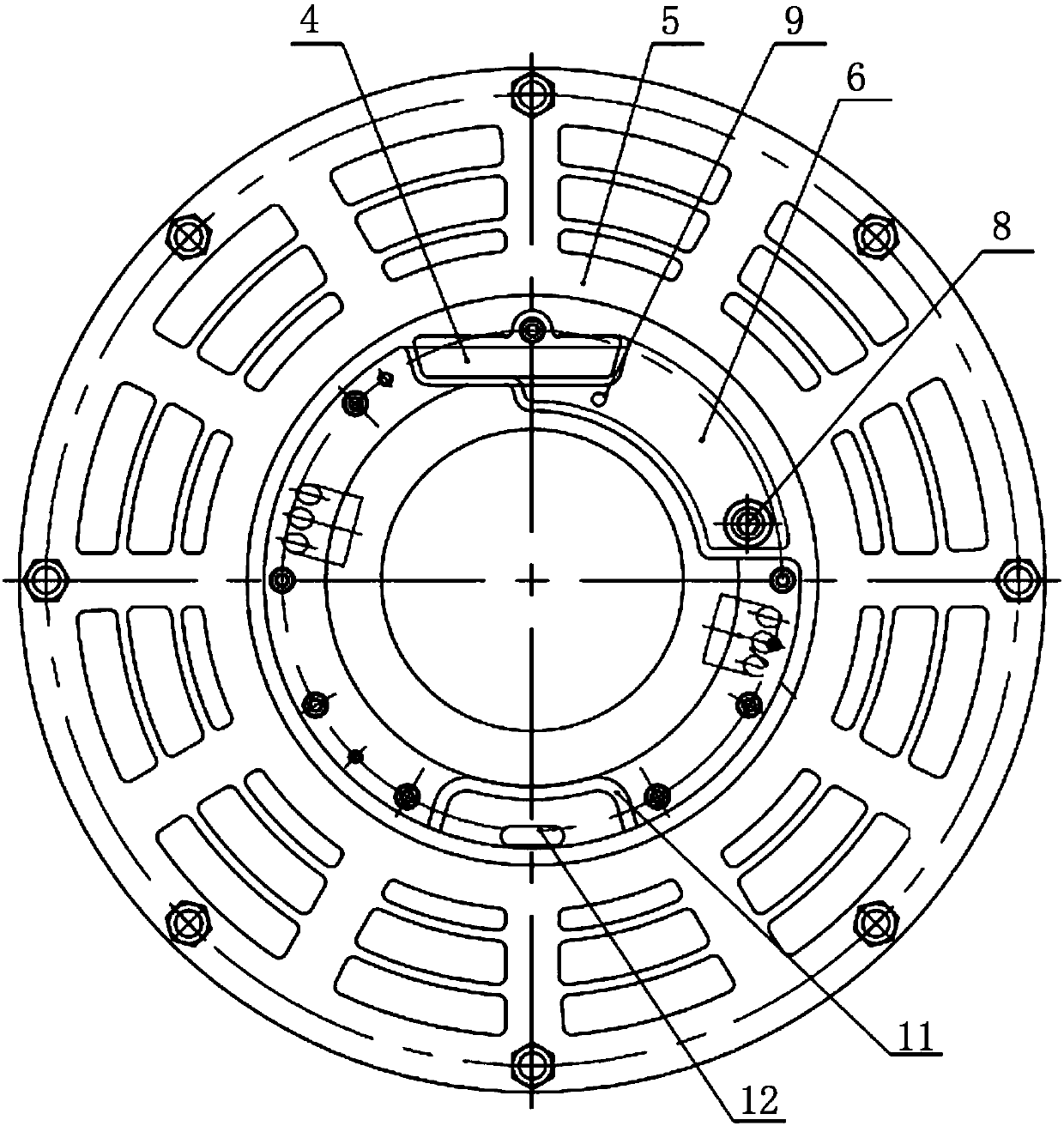

[0025] Please refer to Figure 3-6 , the embodiment of the present invention locomotive motor bearing lubrication structure, the motor includes bearing outer cover 18, rotating shaft 19, bearing inner cover 20, bearing 21, end cover 5, rotating shaft 19 is supported on the end cover 5 by bearing 21, bearing inner cover 20, The outer bearing cover 18 is mounted on the inner and outer sides of the bearing 21 respectively, and the rotating shaft 19 extends out of the motor 10 to cooperate with the gear box 1 .

[0026] An oil filling box 4 is arranged on the bearing outer cover 18. During specific implementation, the oil filling box 4 is fixed on the bearing out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com