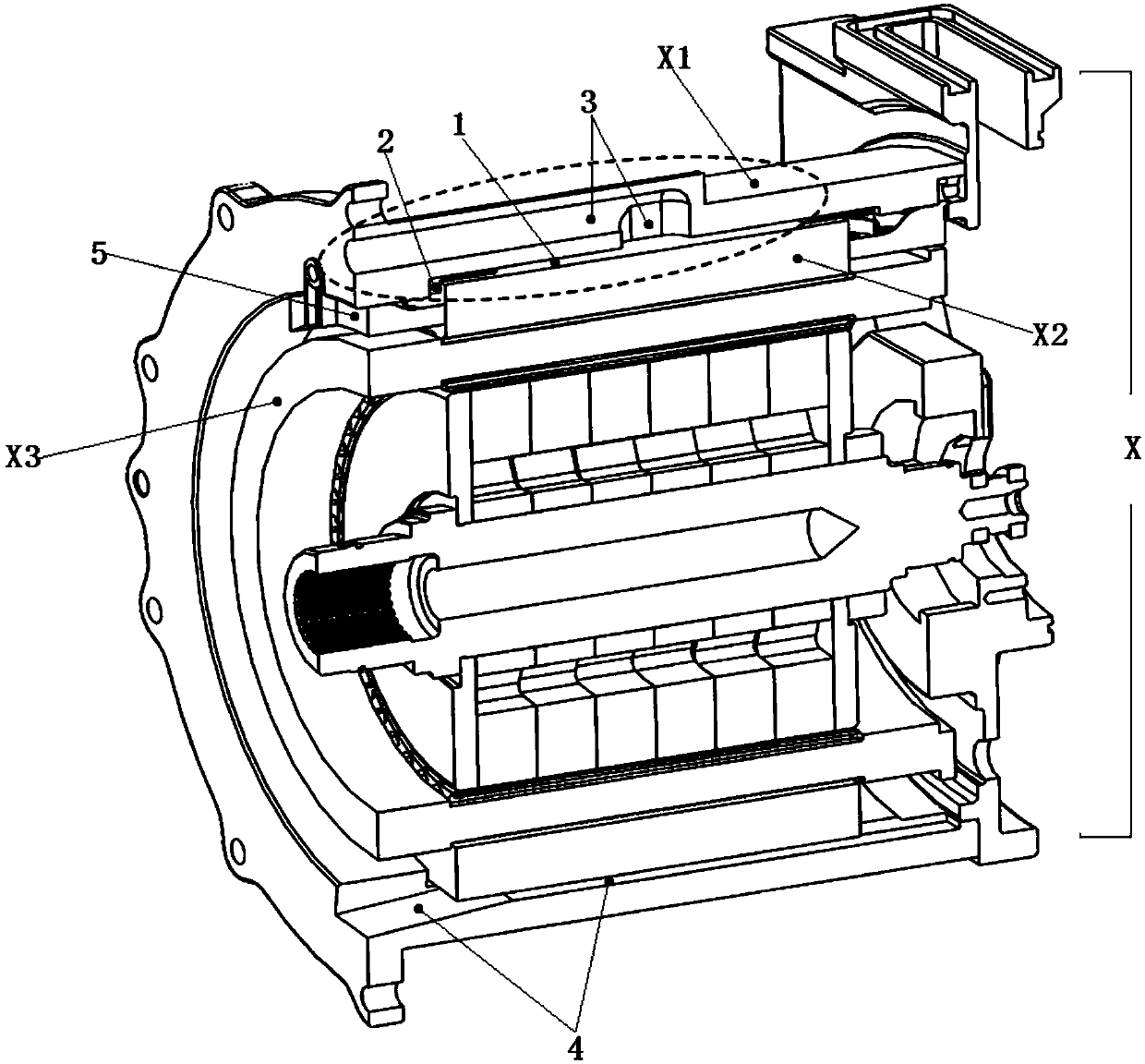

Motor, power assembly, power equipment and motor cooling method

A powertrain and cooling oil technology, applied in the fields of motors, power equipment and motor cooling, powertrains, can solve the problems of increasing the volume of the casing, difficult to ensure sufficient cooling, etc., to reduce the thickness, meet the heat dissipation, strong adaptability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

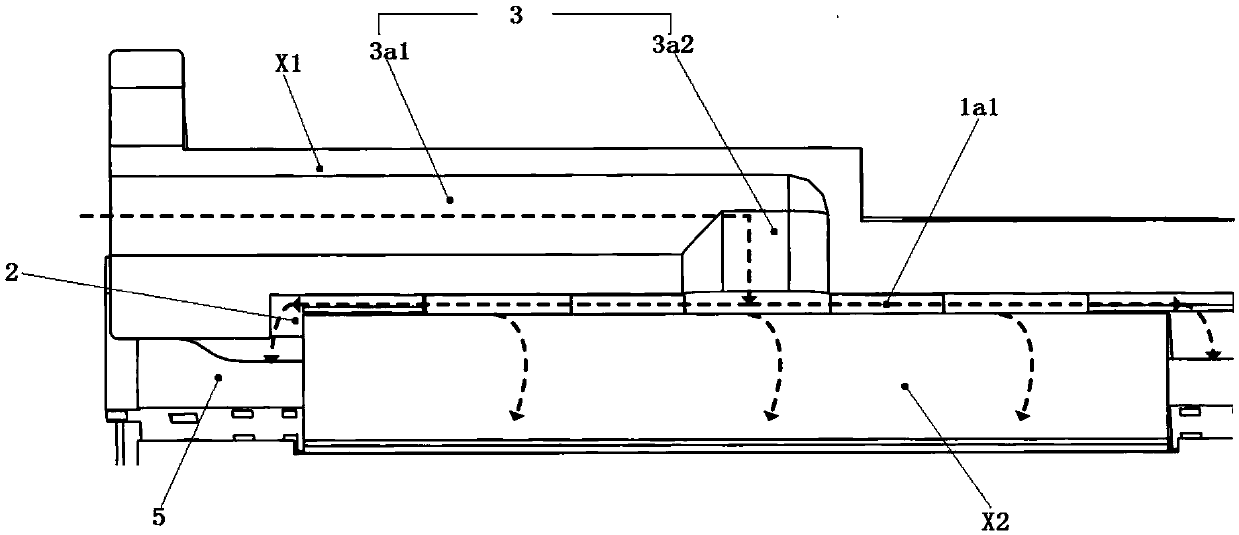

[0209] In this embodiment, the oil inlet of the oil inlet passage 3 will be located outside the top wall of the casing X1, which is beneficial to reduce the length of the oil inlet passage 3 . However, it can be understood that at this time, the motor X will not be able to integrate the oil circuit with the reducer Y.

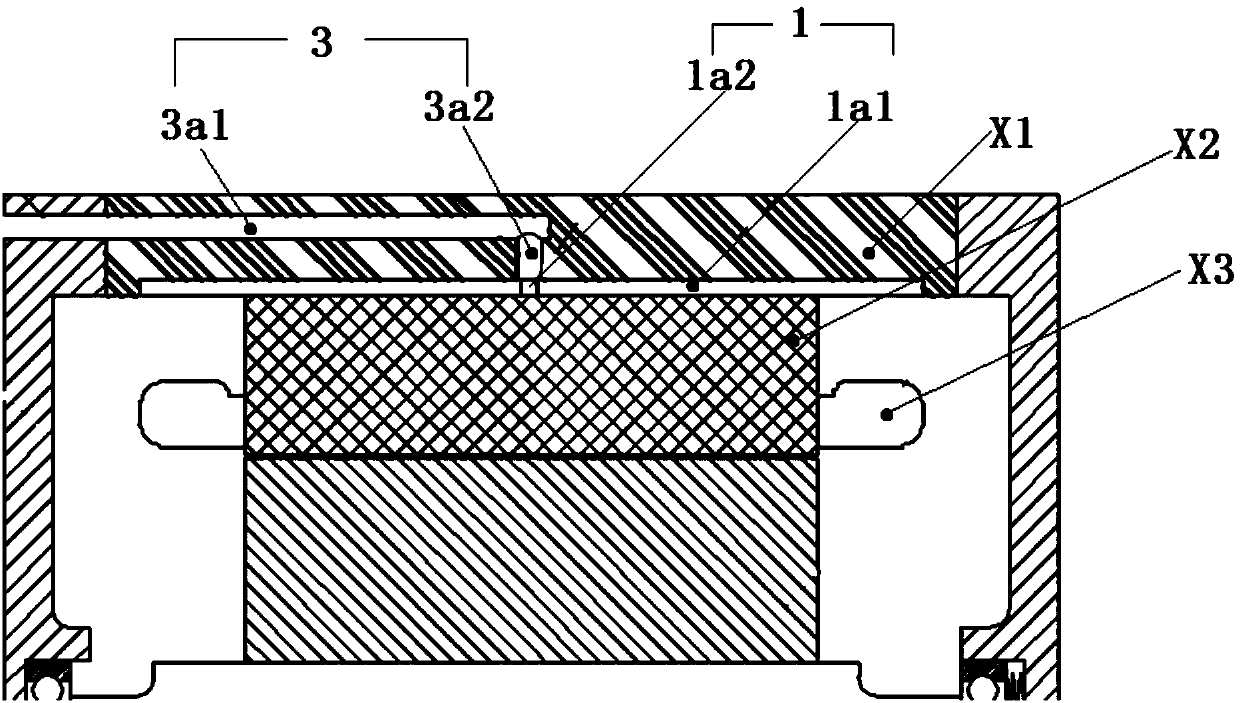

[0210] (4) As for the oil outlet channel 4, it is arranged in the lower part of the casing X1 and communicates with the lower part of the cold stator oil groove 1 and the lower part of the annular space between the casing X1 and the end winding X3. The following gives an example description of the structure of the oil outlet channel 4:

[0211] (4-1) As the first example

[0212] as attached image 3 As shown, the oil outlet channel 4 includes: an oil collecting groove 4a1, which is opened at the bottom of the first inner wall of the casing X1 and communicates with the cold stator oil groove 1;

[0213] The oil drain groove 4a2 is opened at the bottom of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com