Automatic production line for poultry slaughtering and processing

An automated production line and poultry technology, applied in poultry processing, slaughtering, meat processing, etc., can solve the problems of complicated visceral removal work, laborious implementation, and low production efficiency, and achieve the effect of simple structure, low equipment cost, and improved processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

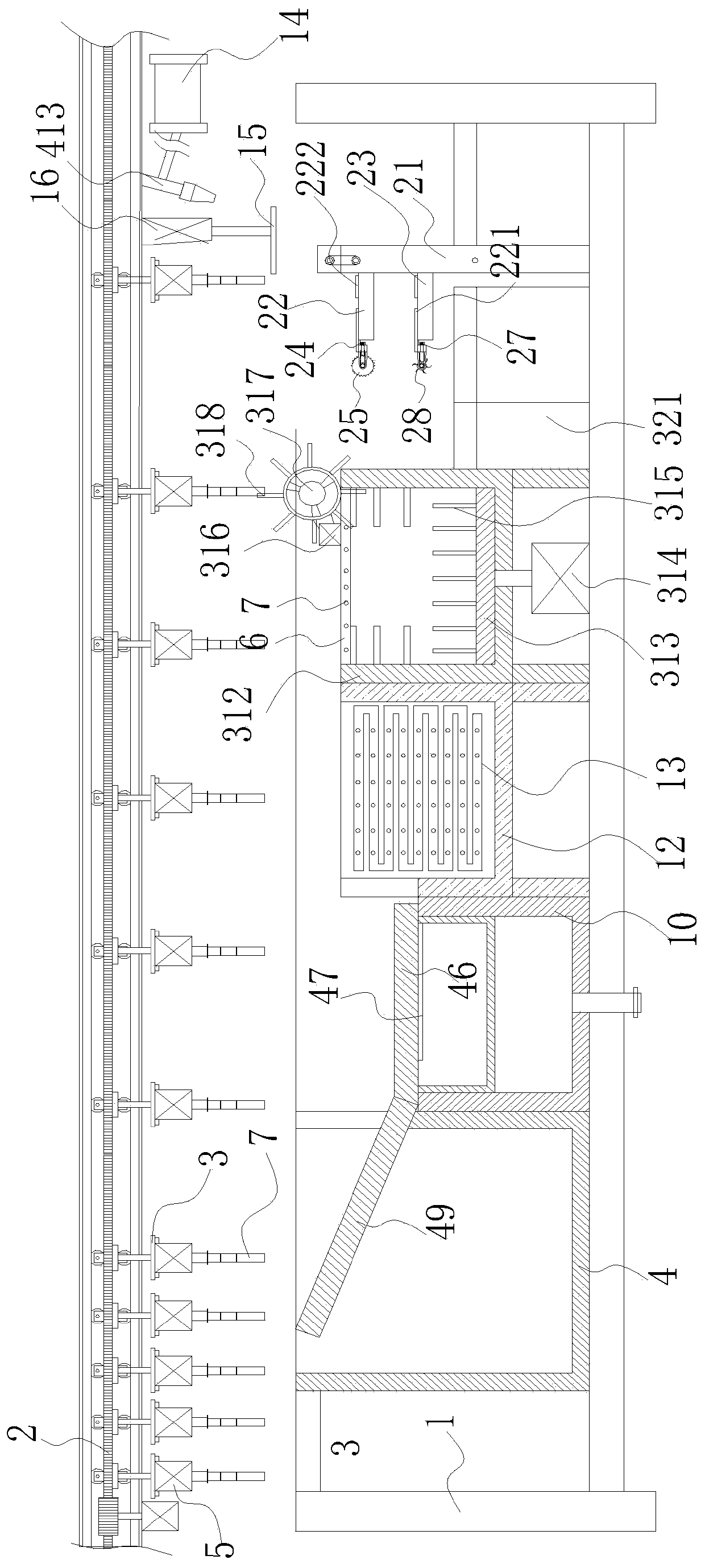

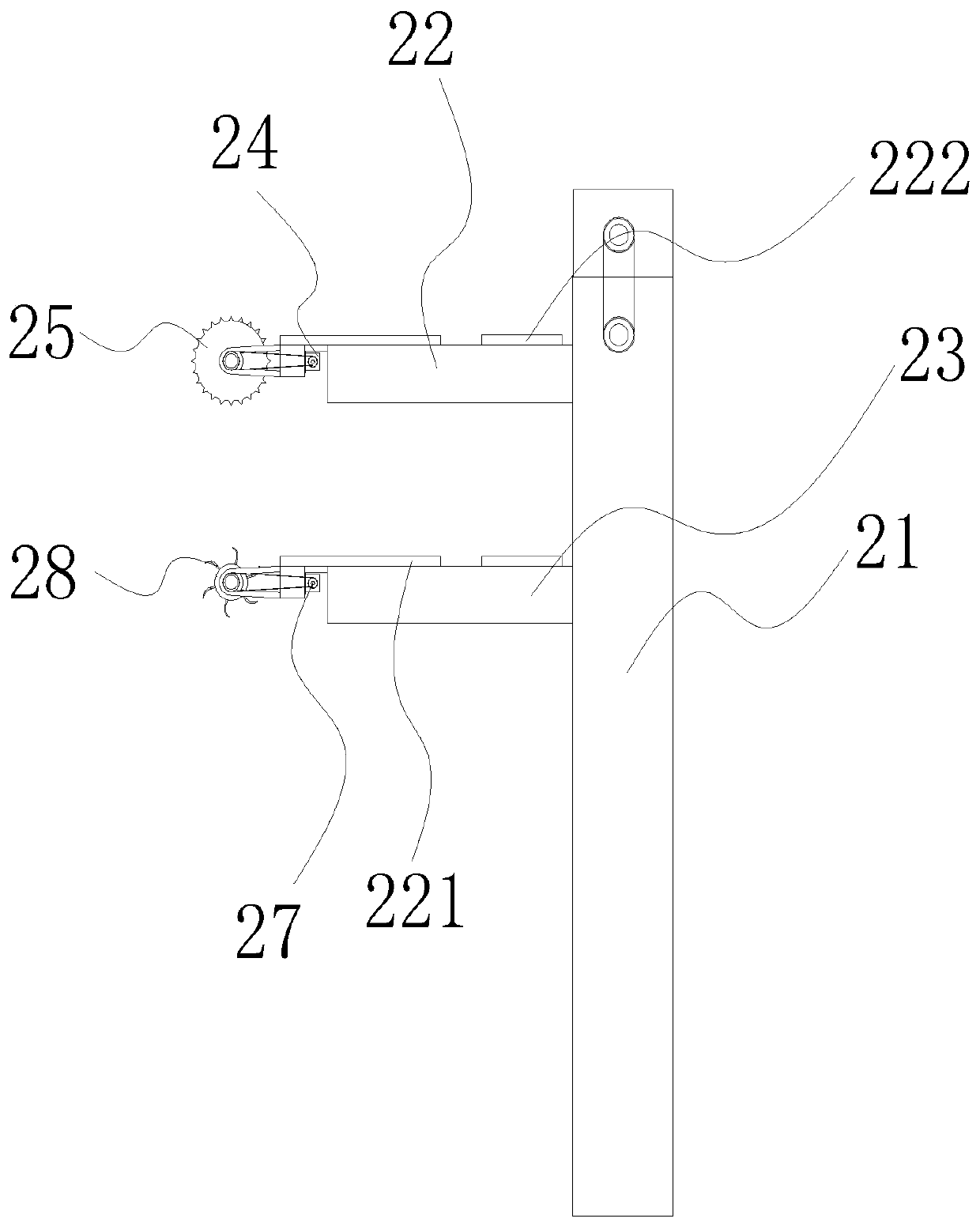

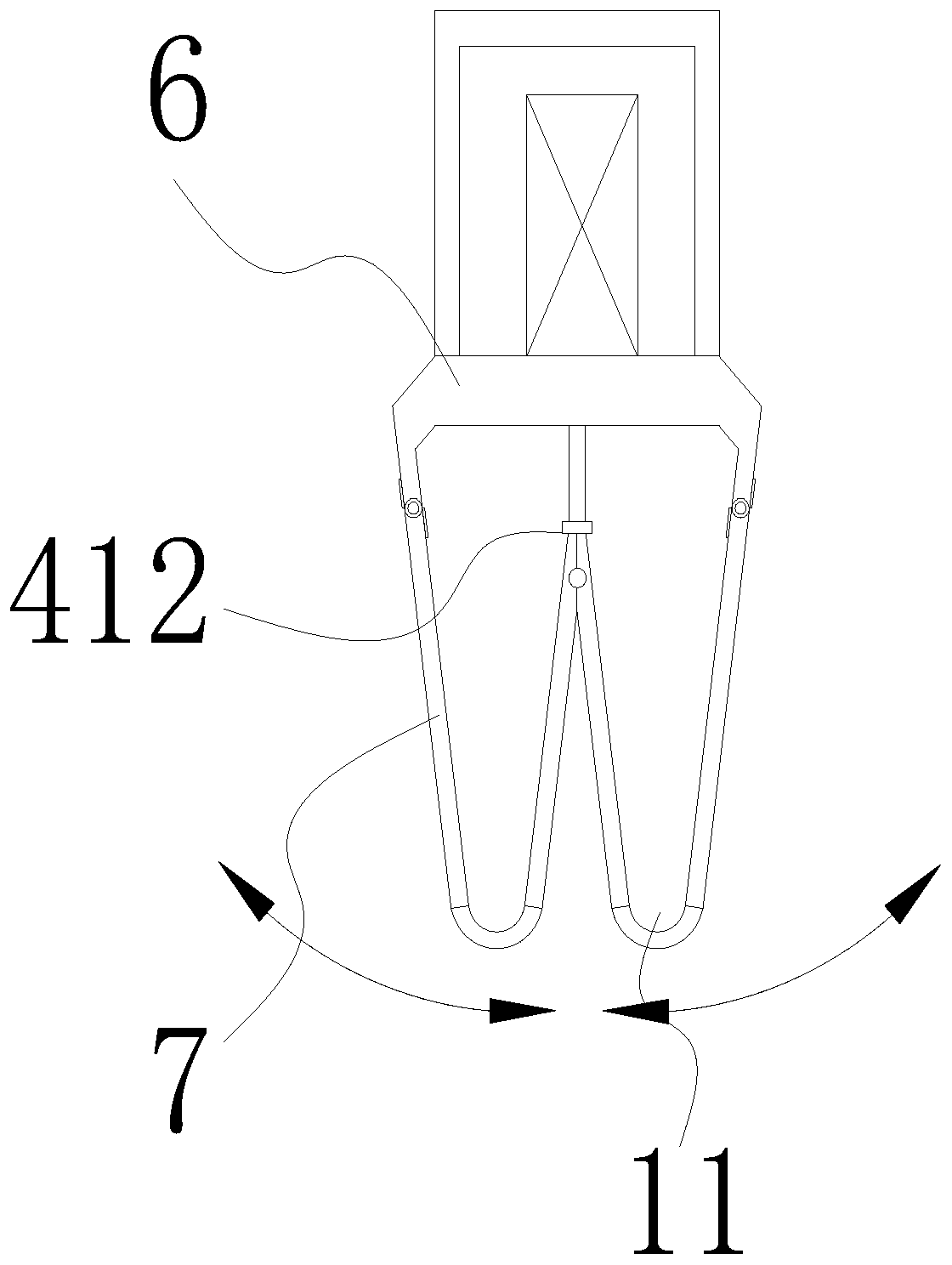

[0022] refer to Figure 1 to Figure 5 , the present invention comprises the transmission chain 2 that is arranged on the top of frame 1 and the hook assembly that is arranged on described transmission chain 2 and is used for hanging poultry, and transmission chain 2 is arranged on the top of frame 1 in ring shape, and described frame 1 A water tank 4 for holding water, a slaughtering mechanism, a scalding mechanism, a depilatory mechanism and an viscera removal mechanism located below the transmission chain 2 are sequentially provided inside, and the transmission chain 2 is provided with a connecting seat 3. The connecting base 3 is rotatably connected to the transmission chain 2 via the rotating shaft, and the lifting cylinder 5 is installed in the connecting base 3, and the lifting cylinder 5 is connected with the hook assembly, and the lifting cylinder can obtain the lowering and extending of the hook assembly. into the water tank 4, slaughter mechanism, scalding mechanism,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com