Highland barley low-GI extruded noodles and making method thereof

A technology of noodles and highland barley, which is applied in the field of highland barley low GI extruded noodles and its preparation, can solve the problems of low GI value, poor cooking quality and palatability of highland barley noodles, high blood sugar, etc., achieve low GI value, meet the needs of staple food, The effect of not raising blood sugar

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The invention also discloses a method for preparing highland barley low GI extruded noodles, which comprises the following steps:

[0031] Step 1, preparation of powder: weigh the following components according to mass percentage: 60-80% of highland barley powder, 15-20% of pea powder, 5-10% of buckwheat flour, 5-10% of quinoa flour, the total of the above mass percentages The amount is 100%, and the weighed components are mixed to prepare powder, and the particle size of the powder is 80-100 mesh;

[0032] Step 2. Weigh the following components in parts by mass: 100 parts of powder, 40-45 parts of water; the pH of the water is 7.0-7.5;

[0033] Step 3. Add water to the powder, stir with a dough mixer for 5-8 minutes, and stir evenly to prepare a mixture;

[0034] Step 4, extruding: adding the mixture into a multi-functional extruding noodle machine for extruding, the extruding temperature is between 110°C and 130°C, and the diameter of the extruded noodles is 0.1-0.2m...

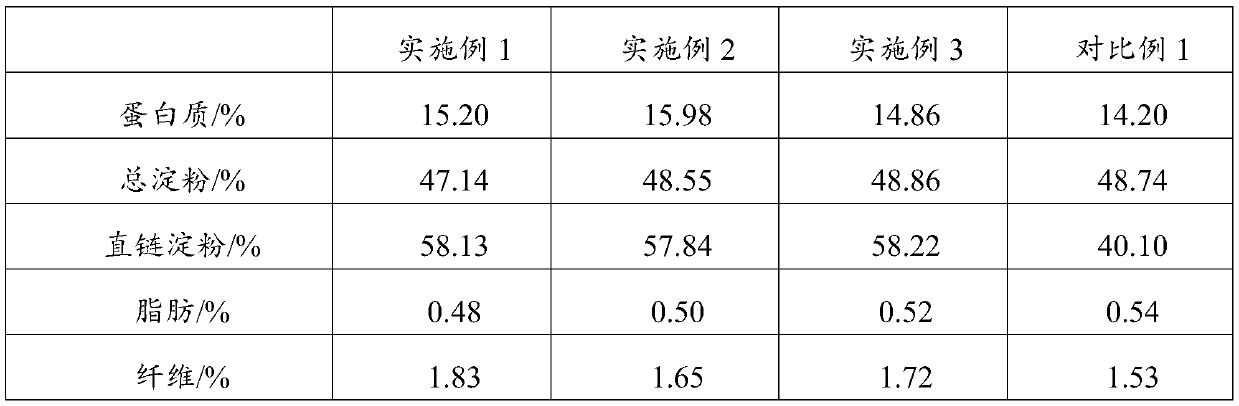

Embodiment 1

[0039] A highland barley low GI extruded noodle comprises the following components in parts by mass: 100 parts of powder and 42 parts of water.

[0040] Wherein, the flour material is composed of the following components according to mass percentage: 70% of highland barley powder, 15% of pea flour, 8% of buckwheat flour, 7% of quinoa flour, and the total content of the above mass percentages is 100%.

[0041] The preparation method of the highland barley low GI extruded noodles is as follows:

[0042] Step 1, preparing powder: mixing the above-mentioned powder components to prepare powder, the particle size of which is 90 mesh;

[0043] Step 2. Add water to the powder, stir with a dough mixer for 6 minutes, and stir evenly to prepare a mixture;

[0044] Step 3, extruding: adding the mixture into a multifunctional extruding noodle machine for extruding, the extruding temperature is 120°C, and the diameter of the extruded noodles is 0.15mm;

[0045] Step 4, freezing and aging:...

Embodiment 2

[0048] A highland barley low GI extruded noodle comprises the following components in parts by mass: 100 parts of powder and 40 parts of water.

[0049] Wherein, the powder material is composed of the following components according to the mass percentage: 80% highland barley powder, 10% pea powder, 5% buckwheat flour, 5% quinoa flour, and the total content of the above mass percentages is 100%.

[0050] The preparation method of the highland barley low GI extruded noodles is as follows:

[0051] Step 1. Prepare powder: mix the above-mentioned powder components to prepare powder, and the particle size of the powder is 80 mesh;

[0052] Step 2. Add water to the powder, stir with a dough mixer for 8 minutes, and stir evenly to prepare a mixture;

[0053] Step 3, extruding: adding the mixture into a multifunctional extruding noodle machine for extruding, the extruding temperature is 110°C, and the diameter of the extruded noodles is 0.1mm;

[0054] Step 4, freezing and aging: th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com