Method for guiding cleaning robot to return to charge base, storage medium and electronic equipment

A technology for cleaning robots and charging bases, applied in the field of cleaning robots, can solve the problems of easy loss of signals, inability to accurately locate the direction of the charging base, and low docking success rate, so as to facilitate popularization and application, improve return charging efficiency, and improve return efficiency. and the effect of the docking success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

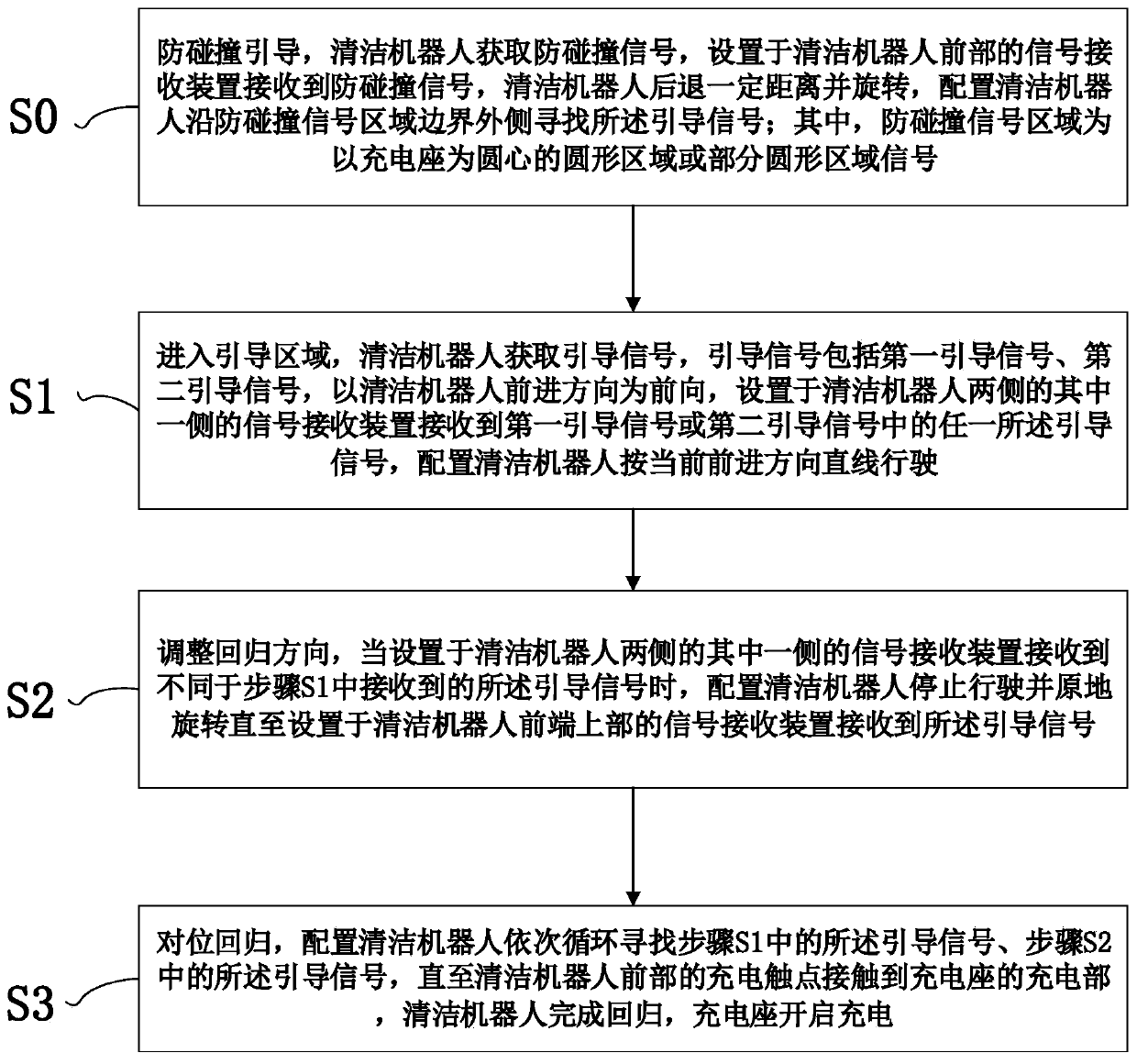

[0043] The cleaning robot drives into the signal area of the charging stand at the first angle 601, and the steps of returning to charging are as follows:

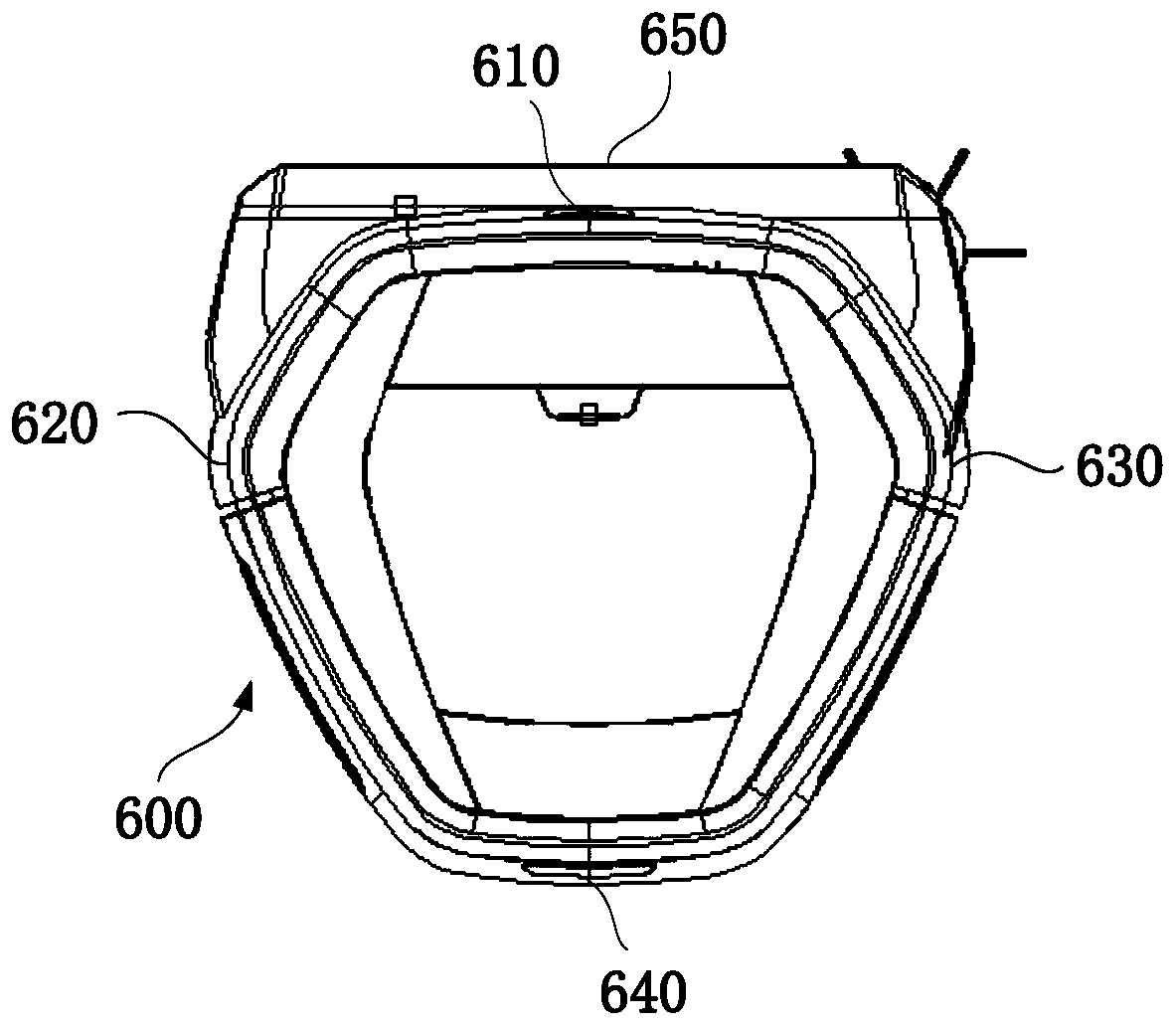

[0044] A1. The fifth signal receiving device 650 of the cleaning robot receives the anti-collision signal of the charging stand, and the robot moves back for a certain distance and rotates 90 degrees counterclockwise;

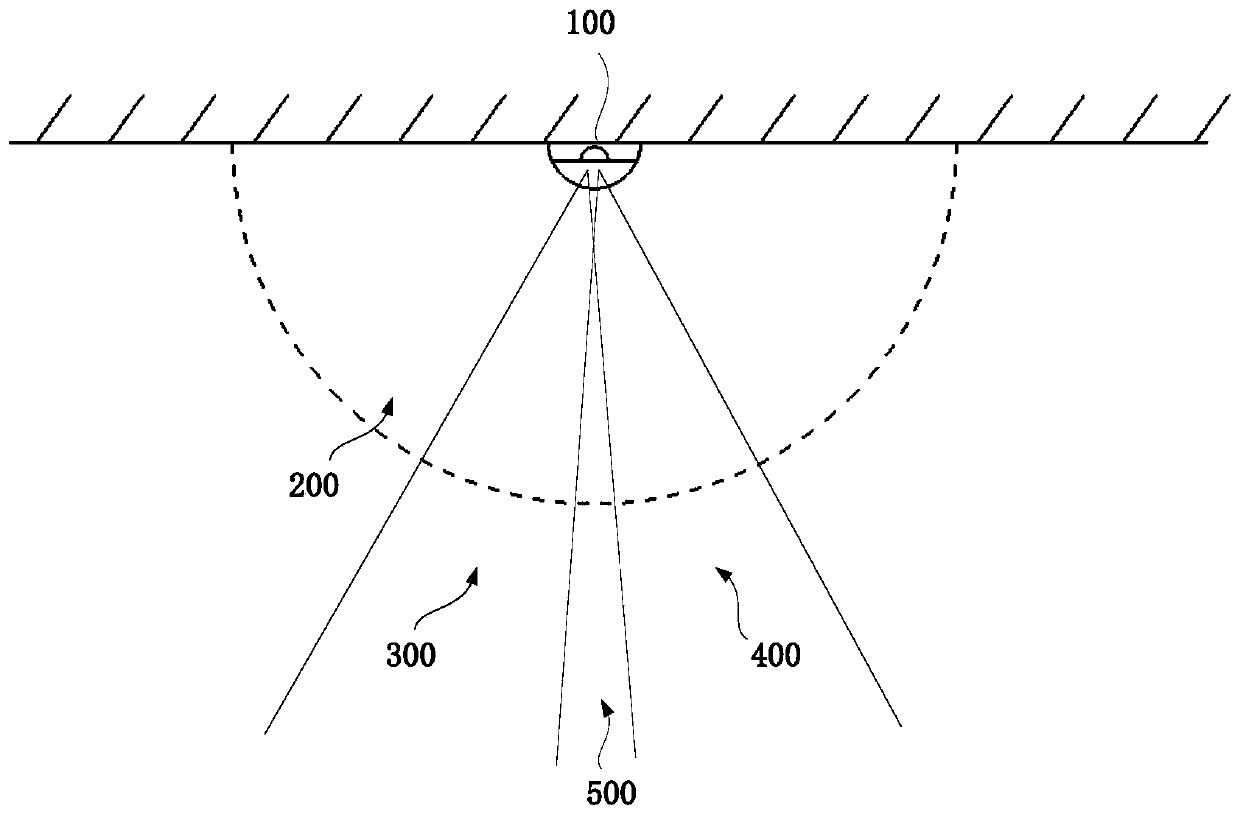

[0045] A2. Configure the cleaning robot with the left wheel fast and the right wheel slow, and drive along the arc outside the anti-collision area 200. When the cleaning robot detects the wall after walking a certain distance, the cleaning robot will back slightly and rotate 180 degrees counterclockwise;

[0046] A3. The cleaning robot then travels along the outer side of the anti-collision area 200 with the slow left wheel and the fast right wheel. When the second signal receiving device 620 of the cleaning robot receives the first guidance signal of the charging stand, the cleaning robot reduces its spee...

Embodiment 2

[0050] The cleaning robot drives into the signal area of the charging stand at the second angle 602, and the steps of returning to charging are as follows:

[0051] B1. The fifth signal receiving device 650 of the cleaning robot receives the anti-collision signal of the charging stand, and the cleaning robot retreats a certain distance and rotates 90 degrees counterclockwise;

[0052] B2. The cleaning robot takes the left wheel fast and the right wheel slow, and walks along the outer side of the anti-collision area 200 in an arc. When the third signal receiving device 630 of the cleaning robot receives the second guiding signal of the charging stand, the cleaning robot slows down and changes to a straight line. , stop walking when the third signal receiving device 630 receives the first guiding signal of the charging base, then the cleaning robot rotates clockwise, and stop rotating when the first signal receiving device 610 receives the first guiding signal of the charging b...

Embodiment 3

[0056] The cleaning robot drives into the signal area of the charging stand at the third angle 603, and the steps of returning to charging are as follows:

[0057] C1. The fourth signal receiving device 640 of the cleaning robot receives the first guiding signal of the charging stand, and the cleaning robot rotates counterclockwise so that the second signal receiving device 620 receives the first guiding signal of the charging stand;

[0058] C2. The second signal receiving device 620 of the cleaning robot receives the first guidance signal of the charging stand, and the cleaning robot continues to move forward in a straight line, and stops walking when the second signal receiving device 620 of the cleaning robot receives the second guidance signal of the charging stand, and then The cleaning robot rotates counterclockwise, and stops rotating when the first signal receiving device 610 receives the second guiding signal of the charging stand;

[0059] C3. The cleaning robot t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com