Dust removal process for network communication equipment network port assembly

A technology for network communication and equipment, which is applied in the field of cleaning technology of network port components of network communication equipment, can solve problems such as chip corrosion, corrosion, and poor contact of network cable access network ports, so as to prevent cleaning dead ends, improve effectiveness, and improve The effect of adsorption treatment effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

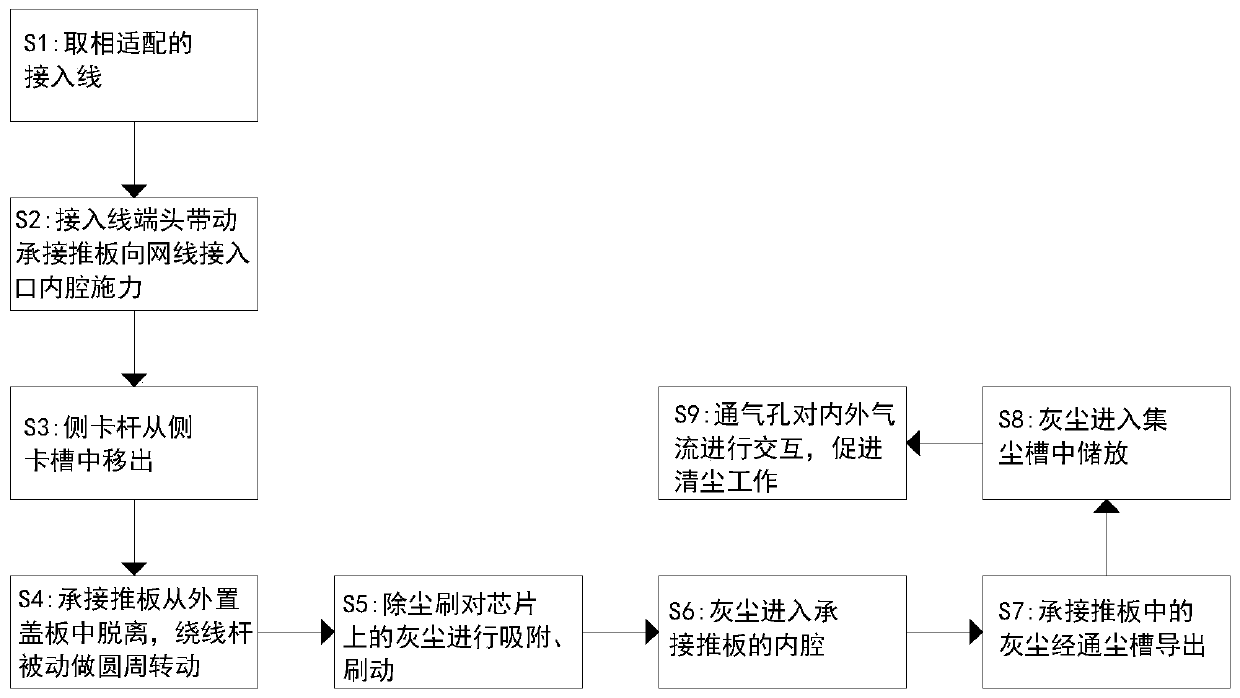

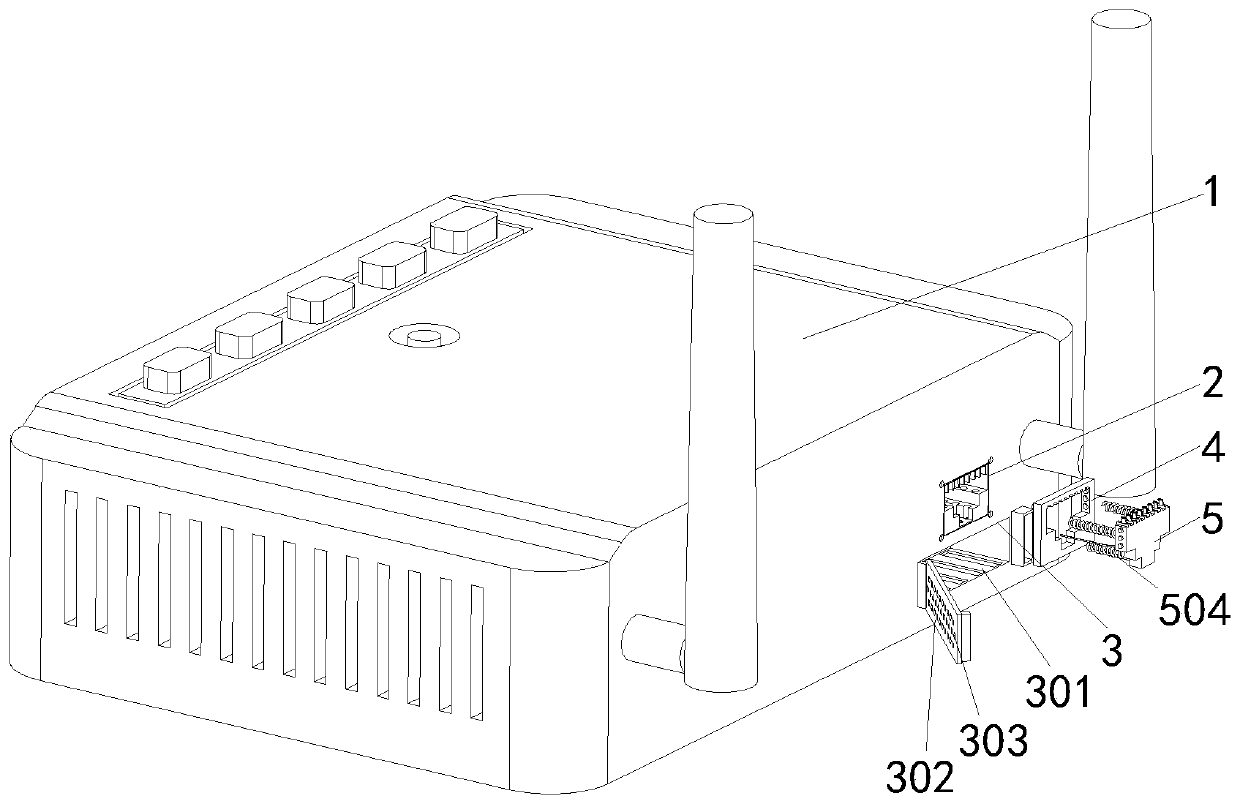

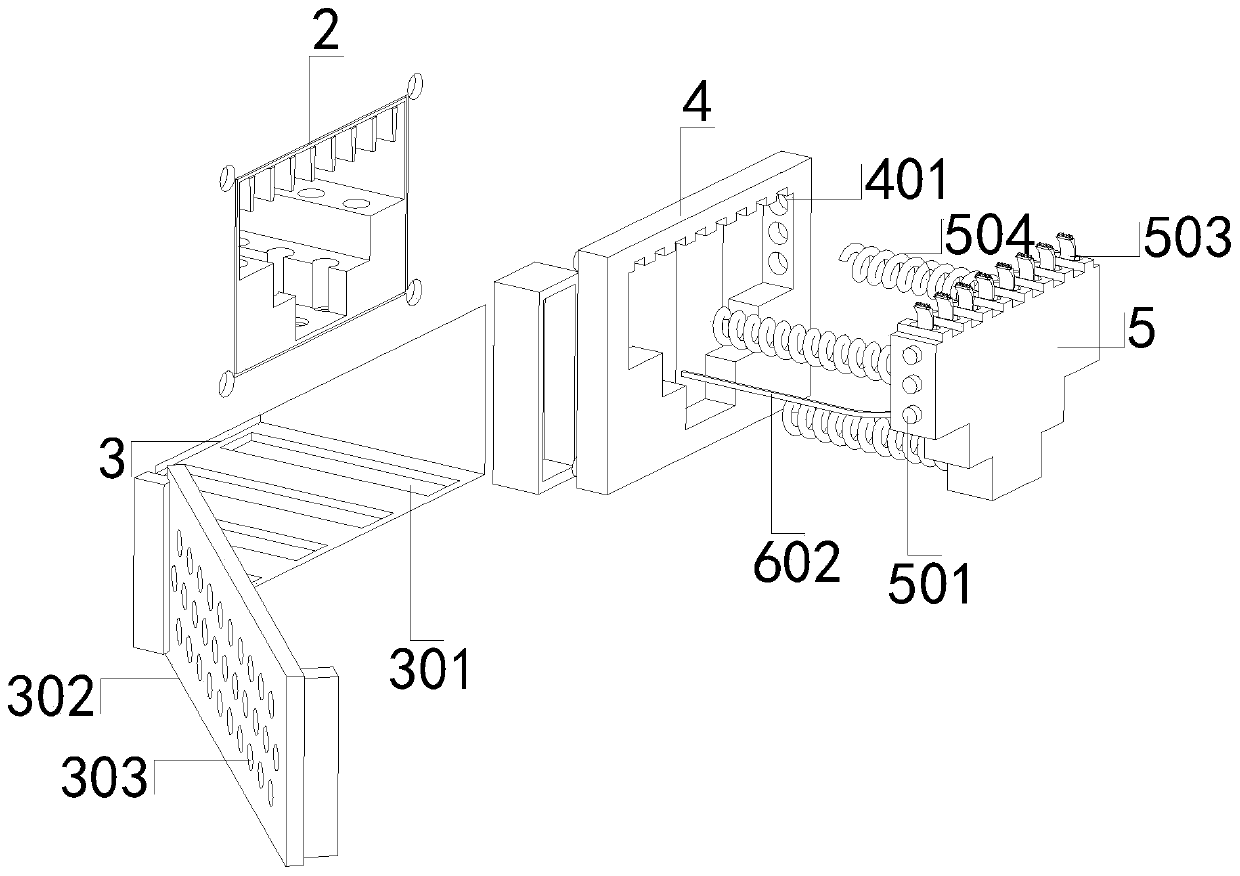

[0038] use Figure 1 to Figure 7 A dust cleaning process for network port components of network communication equipment according to the present invention is described as follows.

[0039] Such as Figure 1 to Figure 7 As shown, a kind of dust removal process for the network port assembly of network communication equipment of the present invention, the process includes the following steps:

[0040] S1: Take the access line that matches the network port on the front of the network communication device;

[0041] S2: Make the end of the access line in S1 stick to the front of the receiving push plate, and apply a force to the inner cavity of the network cable access port on the receiving push plate;

[0042] S3: During the process of inserting the end of the access cable into the inner cavity of the network cable inlet in S2, the side clamping rod deforms and moves out of the side clamping slot;

[0043] S4: After removing the middle side clamping rod of S3 from the side clamp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com