A welding positioning device for a door panel column

A welding positioning and column technology, applied in welding equipment, auxiliary equipment, auxiliary welding equipment, etc., can solve the problems of inability to position welding, etc., achieve the effect of reducing operation labor intensity, avoiding deviation and dislocation, and ensuring stable positioning welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

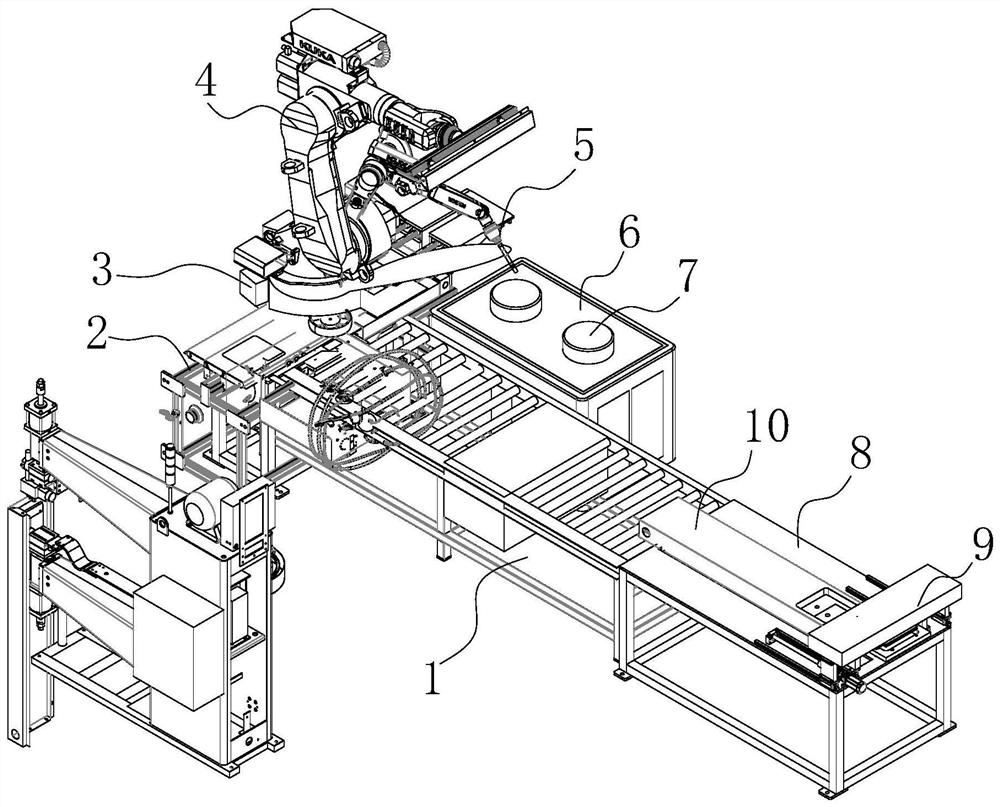

[0019] like Figure 1-3 As shown, the present invention provides a technical solution: a welding positioning device for a door panel column, including a machine platform 1, the rear side of the machine platform 1 is fixedly connected with a transverse drive mechanism 2, and the top of the transverse drive mechanism 2 is fixedly connected with a rotating device Mechanism 3, a mechanical arm 4 is fixedly installed on the top of the rotating installation mechanism 3, a welding hand 5 is fixedly connected to the mechanical arm 4, a placement platform 6 is fixedly installed on the right side of the machine table 1, and a column body 7 is placed on the top of the placement platform 6 , The front side of the machine platform 1 is fixedly installed with a conveying platform 8 , a positioning mechanism 9 is installed on the top of the conveying platform 8 , and a door panel body 10 is placed on the top of the conveying platform 8 .

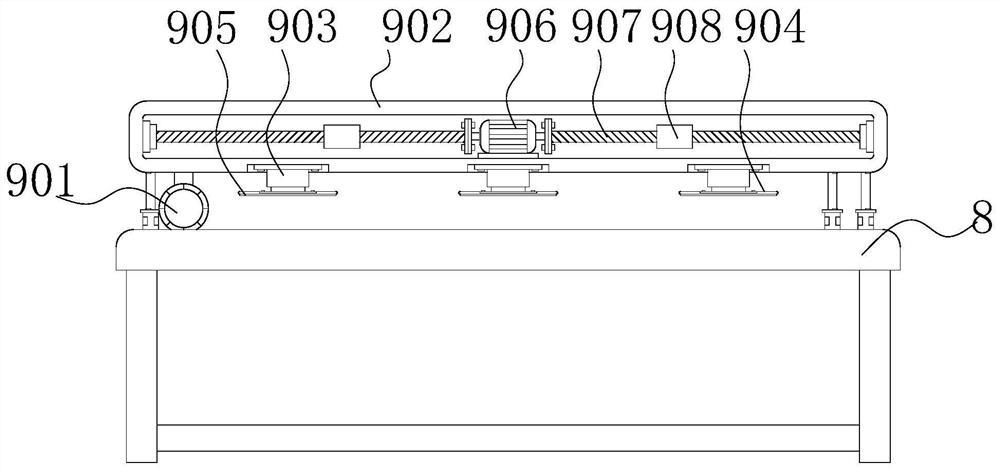

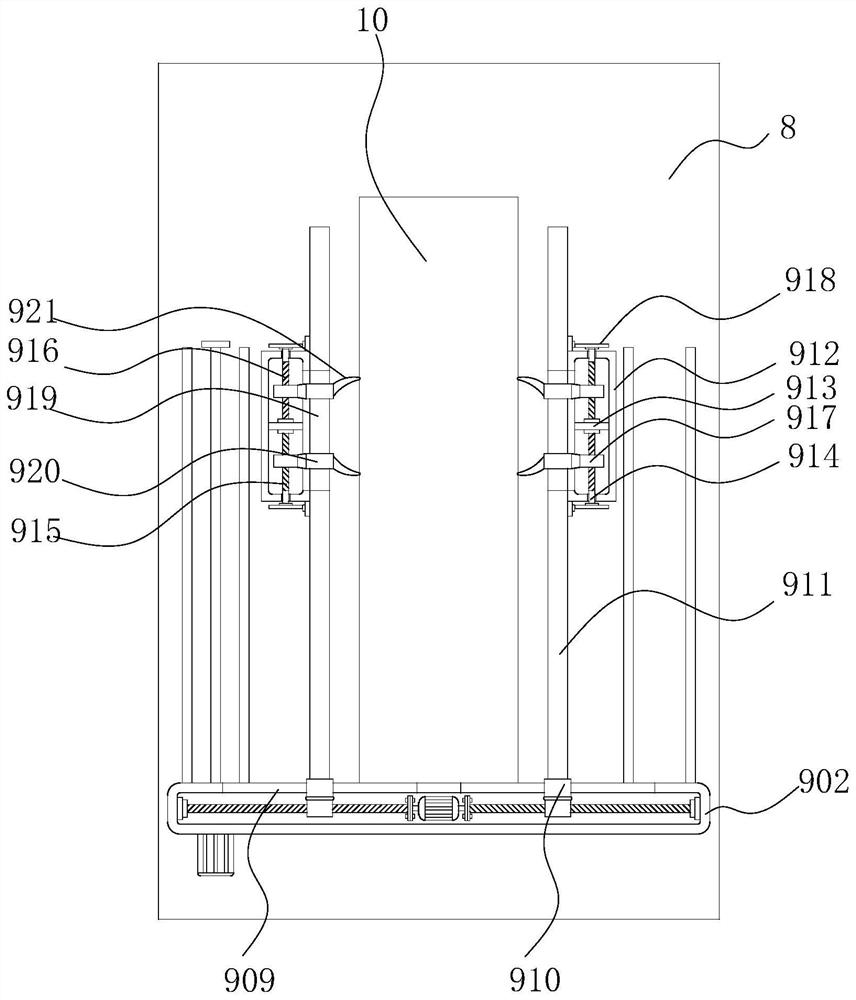

[0020]The positioning mechanism 9 includes a longitu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com