Preparation method and application of 3D printing silicon oxynitride ink without organic deposition phase

A 3D printing, silicon oxynitride technology, applied in the direction of additive processing, can solve problems such as deformation, cracking, leaving pores, etc., to achieve the effect of simple preparation process, inhibition of viscosity increase, and avoidance of pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

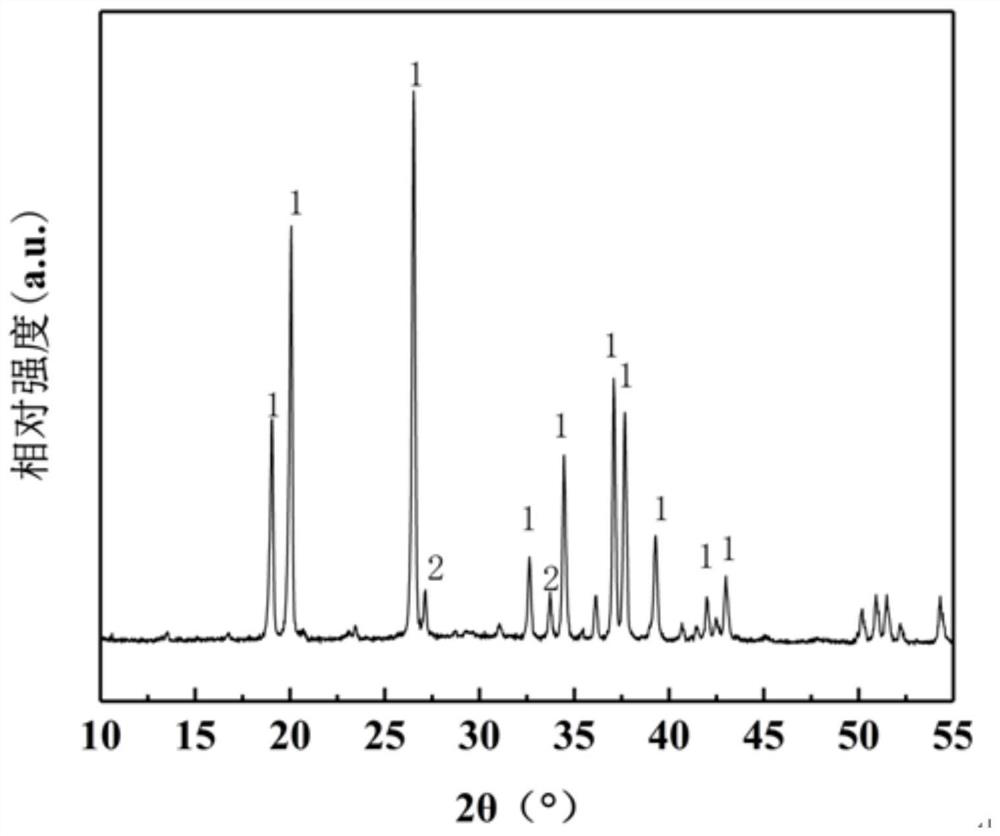

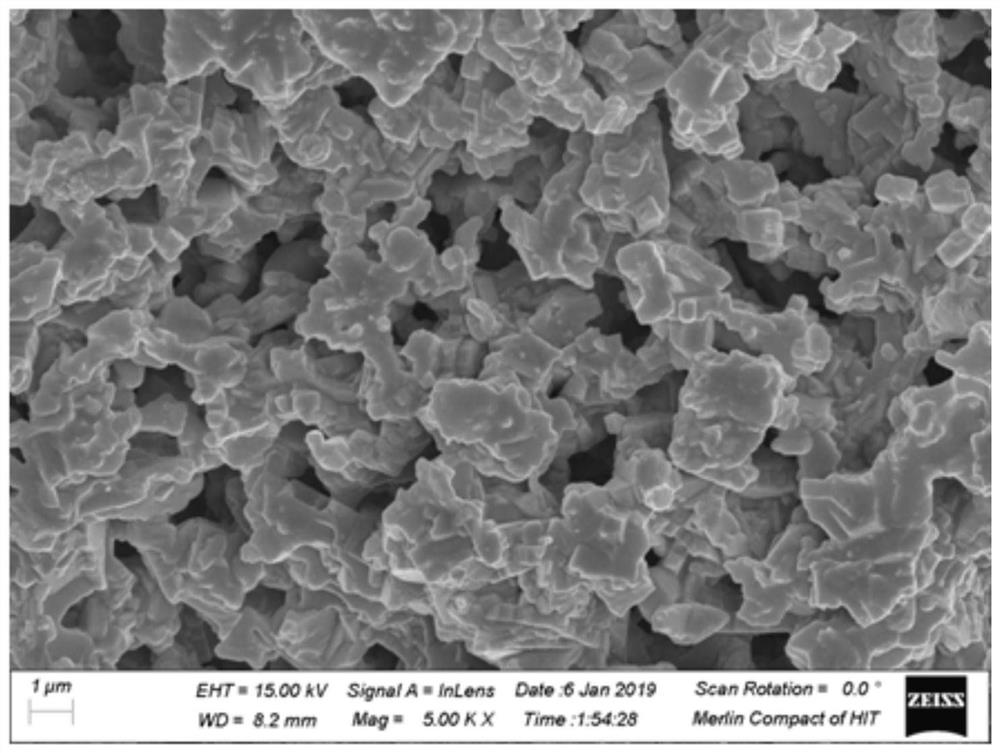

Image

Examples

specific Embodiment approach 1

[0022] Specific Embodiment 1: In this embodiment, the preparation method of 3D printing silicon oxynitride ink without organic deposition phase is carried out according to the following steps:

[0023] 1. Mix silicon nitride, silicon dioxide and sintering aids to obtain mixed raw materials, then ball mill the mixed raw materials, dry them after ball milling, and finally obtain mixed powder after screening;

[0024] 2. Add tetraethylene glycol dimethyl ether and n-hexanol to the mixed powder in step 1 and mix to obtain a solid-liquid mixture;

[0025] The volume fraction of the mixed powder in the solid-liquid mixture described in step 2 is 21.50-21.80 vol%, the volume fraction of tetraethylene glycol dimethyl ether is 69.15-69.35 vol%, and n-hexanol is the balance;

[0026] 3. Mechanically stir the solid-liquid mixture obtained in step 2 for 0.5 to 1 hour to obtain uniformly mixed ink, which is completed; in step 3, mechanical stirring can make the solid-liquid mixture evenly ...

specific Embodiment approach 2

[0030] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the ball milling process described in step one is: the corundum ball and the mixed raw material are loaded into the ball milling tank according to the mass ratio of the ball to material (4~8):1, and Anhydrous ethanol is added into the ball mill tank as a medium, and then the ball mill is not less than 12 hours under the condition that the speed of the mixer is 100-300 rpm. Other steps and parameters are the same as those in the first embodiment. The ball milling process in this embodiment can ensure uniform mixing of raw material powders.

specific Embodiment approach 3

[0031] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the drying process in Step 1 is: stirring and evaporating to dryness in a water bath at 80-90°C. Other steps and parameters are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com