Cable-stayed steel truss cooperative system bridge

A technology for steel trusses and bridges, applied in the field of cable-stayed steel truss cooperative system bridges, can solve the problems of cluttered vision, low bearing capacity, and many rods, and achieve the effect of improving wind resistance stability and good dynamic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

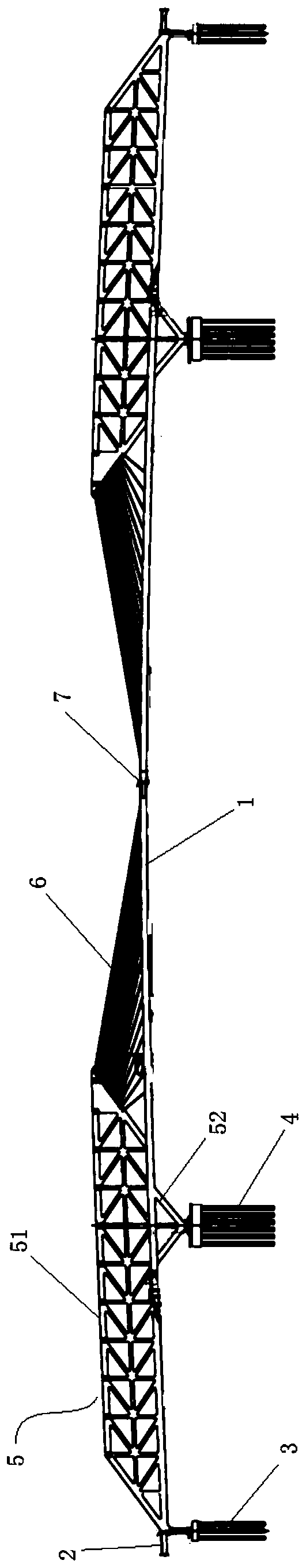

[0023] A cable-stayed steel truss collaborative system bridge, such as figure 1 As shown, the bridge includes a main bridge 1 and an approach bridge 2 connected to both ends of the main bridge 1. A transfer pier 3 is set at the junction of the main bridge 1 and the approach bridge 2, and two middle piers 4 are set in the middle of the main bridge 1. The distance between 3 and middle pier 4 is 160m, and the total span of main bridge 1 is 785m. Both ends of the main bridge 1 are provided with a steel truss cantilever beam 5 structure, including the parallelogram structure of the upper part 51 and the V-shaped structure of the lower part 52. There are cables 6 between the inner end of the upper part 51 and the main bridge 1. The main bridge 1 There are expansion joints and rigid hinges 7 in the middle to transmit longitudinal and transverse bending moments and shear forces, and release temperature forces.

[0024] Specifically:

[0025] The main bridge adopts a cable-stayed and cant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com