Control system for improving accuracy of belt weighers under bad working conditions and control method of control system

A control system and belt scale technology, applied in the direction of continuous material flow weighing equipment, measuring devices, instruments, etc., can solve the problems of difficult requirements, limited use of belt scales, high requirements for the use environment, etc., and achieve the goal of improving the technical level Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

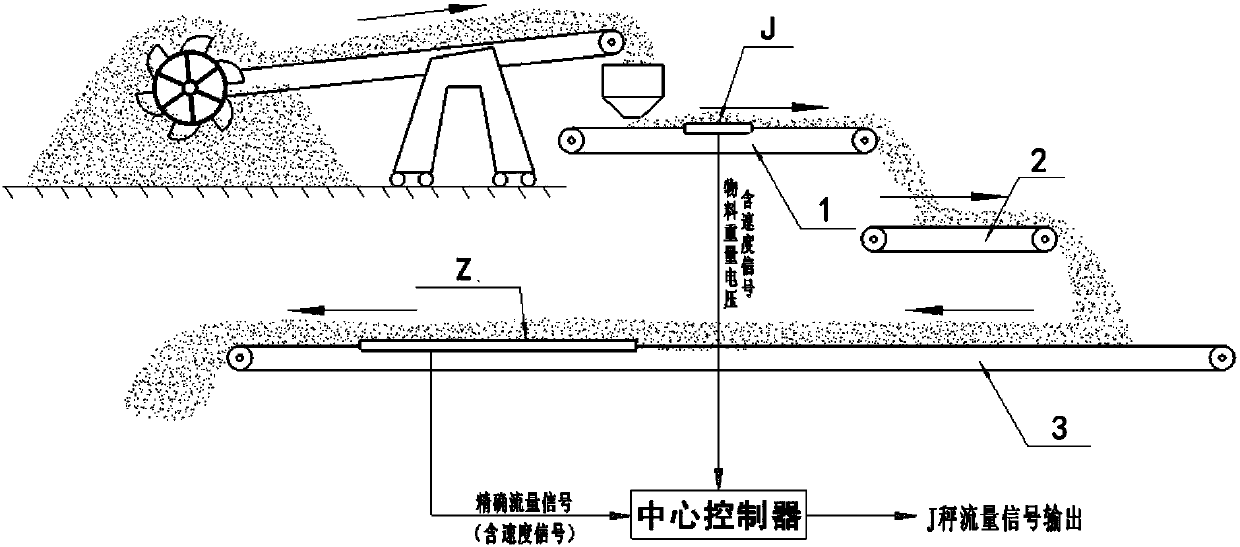

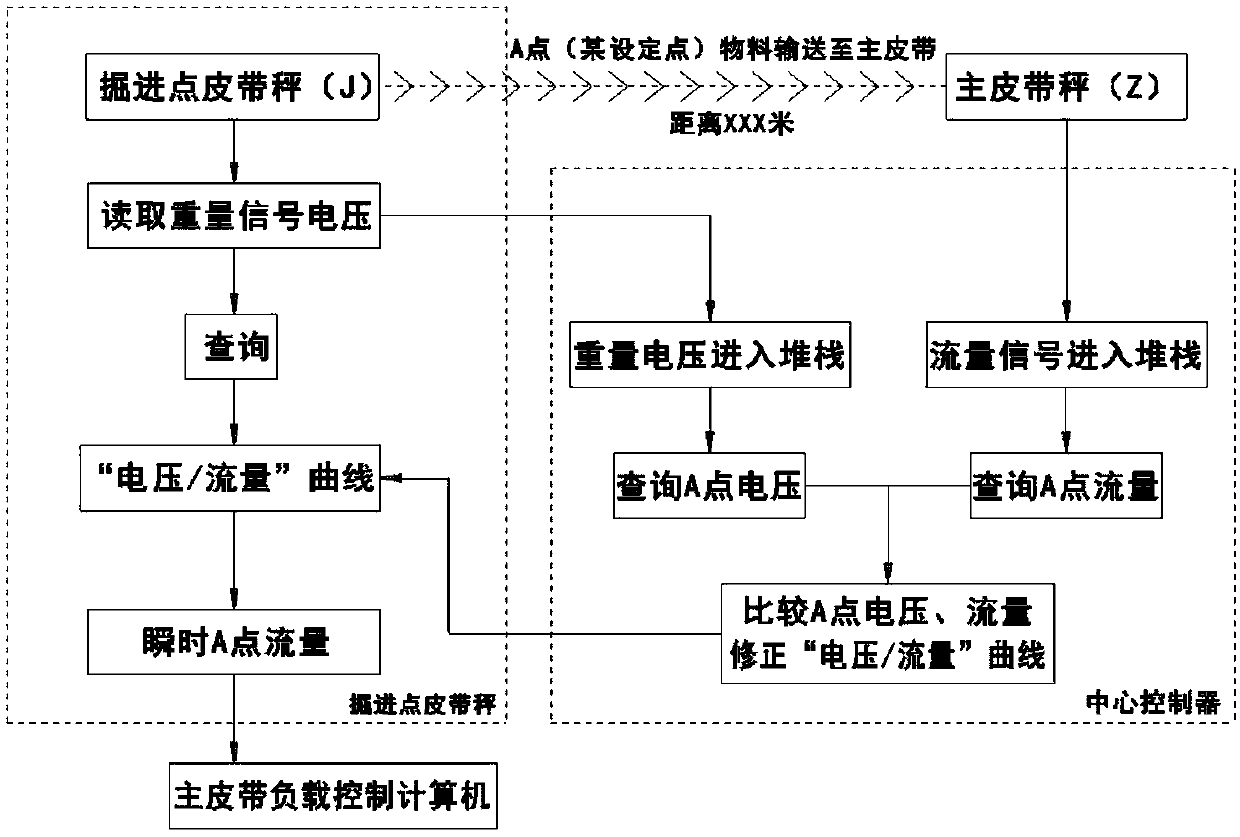

[0032] This embodiment provides a control system for improving the accuracy of belt scales under harsh working conditions, the structure is as follows figure 1 with figure 2 As shown, it includes the belt scale J at the excavation point, the intermediate transport belt 2, the main belt scale Z and the central controller; the belt scale at the excavation point adopts the single-point suspension weighing unit in the array belt scale, and the main belt scale adopts the array belt Scale; excavation conveying belt 1 connects main conveying belt 3 through intermediate conveying belt 2; excavation point belt scale is installed on the excavation conveying belt 1 at the excavation point, collects the weight signal of the transported material nearby, and compares the signal and the corresponding speed signal They are transmitted together to the central controller; the main belt scale is installed on the main conveyor belt 3 following the excavation conveyor belt to accurately collect t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com