Partition flotation system

A flotation and flotation cell technology, applied in flotation, solid separation, etc., can solve problems affecting flotation effect, particle shedding, large maintenance, etc., to achieve flotation efficiency and flotation effect guarantee, and convenient partitioning The effect of flotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

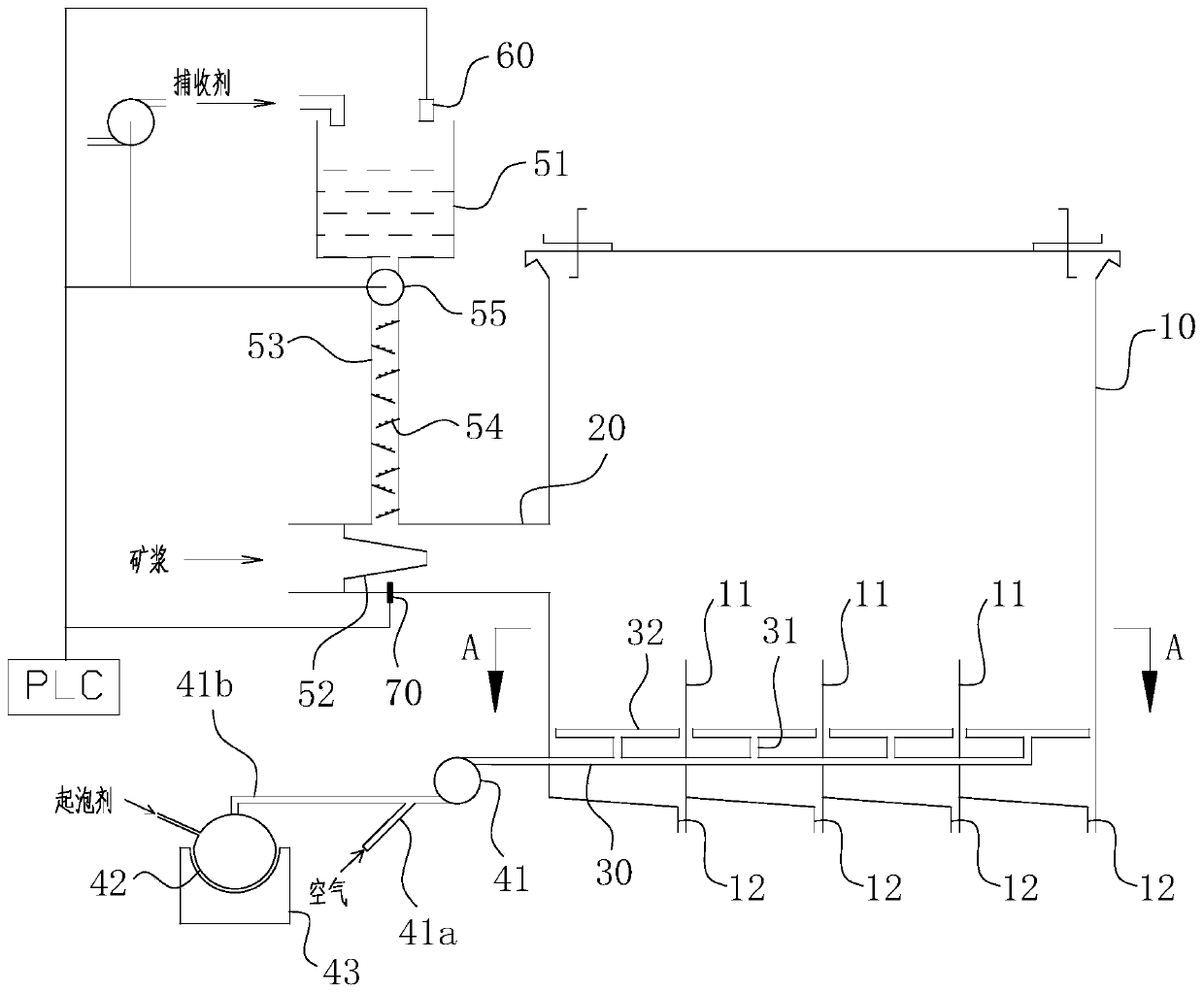

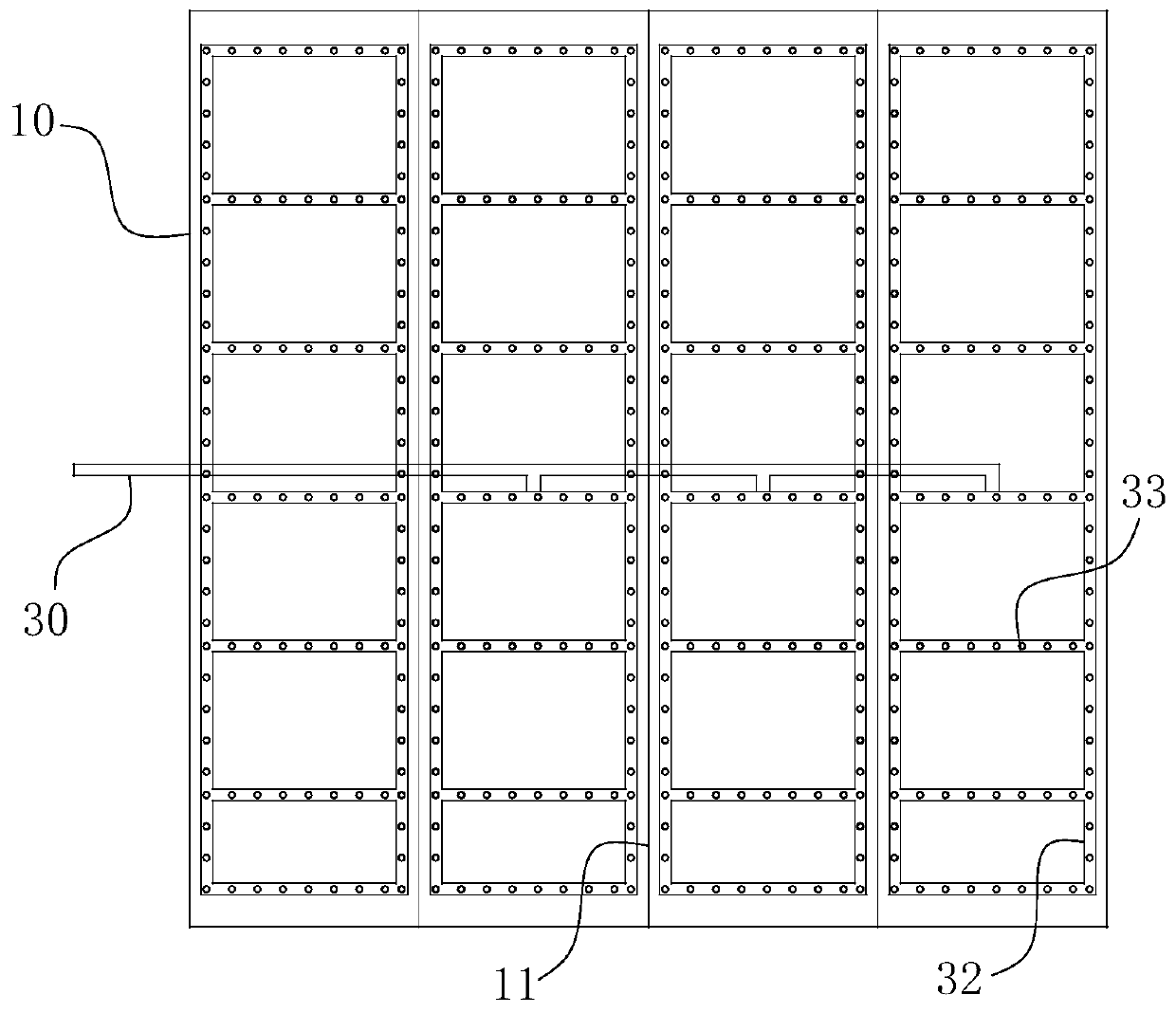

[0031] For ease of understanding, combined here Figure 1-2 , the specific embodiments of the present invention are further described as follows:

[0032] The specific components of the present invention are divided into three major modules, including: a flotation cell 10, a liquid inlet assembly and an air inlet assembly. in:

[0033] Flotation cell 10 appearance reference Figure 1-2As shown, it includes a square trough-shaped trough with its opening facing upwards. A through hole is provided on the left side of the flotation cell 10, and a mixed slurry injection pipe 20 extends from the through hole, so as to inject the mixed slurry. Along the spray path of the mixed slurry, to Figure 1-2 The structure shown is taken as an example. At the bottom of the flotation cell 10, there are three vertical partitions 11 distributed from left to right with the plates vertical and parallel to each other. The three sets of vertical partitions 11 are extended from end to end and fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com